Icolor Lf700+label Finishing System

Get Price Quote

LI-4600 weighing labeling system

Get Price Quote

A simple automatic weighing and labeling system start-stop type. Maximum speed in 20 packs weighing mode minute, Ethernet Network Ready,10.4 " color touch screen TTF,Printer: thermal head with memory management, which enables high quality printing at 200 dpi.

Best Deals from Label Systems

Label Inspection System

800,000 Per Piece

1 Piece(s) (MOQ)

Sno description specifications: model : optomech - label inspection system speed : up to max 200 bottles per minute. bottle size : height 200 mm max : width or diameter 95 mm max advanced machine vision software with the following features: � shows the picture of the bottlelabel being inspected on screen. � list�s the frequency of errors and displays on the screen. � signals the ejection of the rejected bottles from the line. � the operator can set the tolerances for each defect. � the operator can save the parameters of each defect in a database and retrieve the same later. � all measurement reports are stored in the database, to be recalled anytime. � reports can be exported to excel. hardware: � data processor and control systems. � touch screen user interface � 2 machine vision cameras. � machine vision lenses. � lighting for the cameras. � photo sensor for detecting the bottles. � pneumatics for ejection of the rejected bottle. � uninterrupted power supply for control systems. � tower light. � ejection verification sensor. � pressure switch. The machine detects the following defects:- � unlabeled bottles. � label upside down bottles. � label shifting (vertical & horizontal ) � tilted label. � wrong label. � half cut label. � double label. � dog ear�s. � 2d datamatrix code validation.

Cab Label Printing System

Get Price Quote

German engineering, can print graphics, liner & 2d barcodes, alphanumeric characters. Less maintenance.

Label Inspection System

Get Price Quote

Begapt label inspection system is 100% automatic quality inspection of the label.System reads all types of barcode,pharmacode ,2d code ,RSS code ,PDF codes batch codes (OCR/OCV) on the production line at very high speed. System Features Multi camera support.. Reads all types of barcode, 2D code, RSS code Pharmacode,PDF code Accurate reading of batch codes(OCR/OCV). omni direction codes reading. Label color inspection. Embossed char reading. Codes printed on aluminum foil. Faulty label rejection. FDA(21 CFR part11) complaint. Extensive reporting module. Remote monitoring.

Vision System for Label

10,500 Per Piece

Label Inspection System

Get Price Quote

Our clients can avail from us Label Inspection System. The Vision System is used in Production line for the 100% quality assurance. It inspects for visible defect in the product/printing at high speed. Vision Inspection is completely replacing Manual inspection using higher accuracy and higher speed compare to Manual Inspection. Applications This system is mainly used for quality assurance in Pharmaceutical Industry, Food & Beverage Industry, Cosmetic Products Industry, Printing Press Industry, Packaging Industry etc. The different applications of system includes : To verify Label Pattern and Color VerificationTo check and verify OCR (Optical Character Recognition), Barcode, Pharmacode, 2D code on Label. These OCR contains the detail of the product like Batch no., M.R.P., Manufacturing Date, expiry date etc.To check & verify the Numbers (Digits/Characters) at the time of Printing on Scratch-Cards, Recharge Vouchers, ATM/Debit/Credit Cards, Lottery Coupon, Application Forms etc.Most useful to �Track N Trace� system which has been recently made compulsory in many countries for Pharmaceutical ProductsTo verify the Printing Quality Technical Specifications It is totally customized solution according to different application and products.This system includes following hardware : High Resolution Ethernet CameraMega-Pixel Vision OpticsHigh Intensity IlluminationIndustrial PC with high ConfigurationSensorsAir/Piston based Rejection SystemThe system is having Software for making decision according pre Defined Criteria.We have VISION PHARMA PLUS software. The software is designed especially for Pharma, Beverage, Cosmetic Products and Printing industries.Camera, Optics and Illumination are used mainly for grabbing image of moving object on conveyor belt at high speed. Then camera transfers image to the Industrial PC(I-PC). Sensor is used to synchronize vision system with machine.There is software in the I-PC, processes and inspects particular image of the product/object and check that inspection criteria are fulfilled or not. If product is failed to fulfill pre-defined inspection criteria, Software generates Rejection signal and transfers that signal to Rejection system so that product is rejected and stores values or images in report file which can be rejected.Rejection System may be Air based or Piston based, depending upon weight and dimension of product. On receiving rejection signal, rejection system rejects/sorts particular defective product from production line.Particularly the printed data may be fixed(static), incremental variable, Random variable etc. In case of Static data, the data is fed once at the time of starting the batch. For Incremental data, data is fed once in the software and increment counter is kept in the software so at every product the counter increased and compare with the data from label. And in case of variable data (specially used in Recharge Voucher, ATM/Debit/Credit Card), the database is loaded in the Software same as in the printer and make it verified with data printed on every card. Industries Where This Product Is Used Pharmaceutical product manufacturerPharma Machinery ManufacturerBeverage Machine ManufacturerBeverage ManufacturerPharma Row Material ManufacturerPrinting Press IndustryScratch Card Machine ManufacturerScratch Card Printing Press IndustryCosmetic Product Machine manufacturerSticker Label Printing IndustryCosmetic Product Manufacturer Features Machine Vision System is PC based Industrial Automation that is used for 100% Quality Assurance at very high speed.Machine Vision System is throughout consistent during the work. No energy decay. 24 Hours availability without failure Closed loop control with maximum accuracyPlenty of data saving and fetchingHigh frequency MeasurementVery law maintenance cost and handling charge

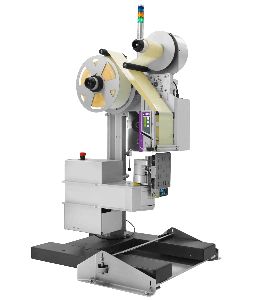

Print and Apply System

200,000 Per Piece

Automatic Overprinting System

Get Price Quote

Label Inspection System

Get Price Quote

1 Piece(s) (MOQ)

100% & whole area inspection on garbled text and print dirt on sticker & label printing for pharmaceutical and beverage

Label Feeding System

Get Price Quote

2200 Pallet Print and Apply Labeling system

Get Price Quote

5 Piece (MOQ)

Labelling System

Get Price Quote

We are manufacturer of labelling system.

Spear Seal

Get Price Quote

The recloseable pressure-sensitive label system from Constantia Flexibles. Using proprietary equipment, Constantia Flexibles prints and applies a pressure-sensitive label to pre-printed flexible film, which is then die cut to provide the consumer with a recloseable feature. Proven label technology Outstanding reclose function Inhouse development / innovation Perfect printing quality

Label Inspection System

Get Price Quote

Our clients can avail from us Label Inspection System. The Vision System is used in Production line for the 100% quality assurance. It inspects for visible defect in the productprinting at high speed. Vision Inspection is completely replacing Manual inspection using higher accuracy and higher speed compare to Manual Inspection.

IML Systems

Get Price Quote

Side Entry Robot Label cassette (Magazine) EOAT (End of Arm Toolings) Static charger Vacuum pump Safety frame Stacking unit (Optional)

automatic labeling systems

Get Price Quote

automatic labeling systems, Grape Varieties, Pomegranates

automatic labeling systems

Get Price Quote

automatic labeling systems, automatic filling system, batching systems

bottle labelling Systems

Get Price Quote

bottle labelling Systems, High speed net weighing bagging machine