Industrial Hydrogenator

190,000 Per Piece

1 Piece (MOQ)

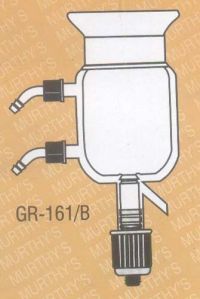

Kilo Lab Glass Reactor

Get Price Quote

A pioneer and a global leader in designing, manufacturing, and supplying the Kilo Lab Glass Reactor and Pilot Plants, Ablaze Export Pvt. Ltd. is here to serve you better with better quality industrial equipment. We manufacture our products using all premium quality materials such as Borosilicate glass, which is used in designing our Kilo Lab Glass Reactor along with the overhead condensers and the heat transfer systems having attached process controls. We manufacture and supply customized Kilo Labs designed with all the necessary and cleverly accessible fill-up points, collecting points, and sampling points to gain significant control of all the processes in the Kilo Lab. We manufacture the glass reactors so transparent that you can have an explicit vision of the entire process and can observe, record data, and analyze the process in real-time for the optimization as per the requirement. Ablaze Export Pvt. Ltd. offers you a wide range of customized distillation systems assembled with the Jacketed Glass Reactor for Kilo Lab. It includes the condensers, vapor column, dean stark, reflux provision, add on and receiver vessels, phase separator, along with various valves placed at an appropriate distance, and all the other supporting metal structures. All our units are supported by the TCU (Thermal Control Unit) that helps the circulation process in the Jacketed reactors. We also manufacture and offer a triple wall glass reactor for the kilo labs and pilot plant that has 50 liters of working capacity. Pertinent Features of Kilo Lab Glass Reactor Suitable for high value, low volume production from 25 liters to 630 liters Transparency for Better Understanding during Process Development Glass Lined Reactor for Cryogenic (-90ºC) Reaction Glass Lined Steel Stirrer for Zero Contamination High mechanical stability & heat transfer Baffle with PT100 temperature sensor provided Twin Distillate Receivers for continuous operation without breaking a vacuum CIP Capable Fundamental Objective The prime objective of the Kilo Lab Glass Reactor is to produce a simulation for flexibility and agility to guide a compelling portfolio of a resulting potential product along with maintaining the standard Environmental Health and Safety (EHS) Policy and the product quality as well. Kilo Lab is known to help in manufacturing the small number of Products from the active pharmaceutical elements and also in evaluating the production as well as the development process before starting the commercialization plant. Kilo labs support the discovery of the fact if the promising product is extensible in the Kilo lab or not and if it can save your business from high expenses and more research time. We do understand the fact that constructing and running a developing process in Kilo Lab only once will never assure that the product with the same potential and qualities will be created in the cGMP manufacturing process. That is why we are in a constant race of developing and designing Kilo Lab Glass Reactor in such a manner that you will be able to test your new processes several times even before shifting them to the development stage in the pilot plant.

Best Deals from Laboratory Reactors

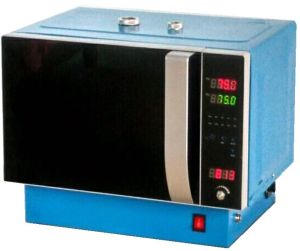

microwave ultraviolet ultrasonic extraction system

9,800,000 Per Piece

1 Piece (MOQ)

This the first of its type microwave workstation. It integrates microwave heating, ultrasonic energy and ultraviolet irradiation, as well as integrates the versatility of performing both open vessel and closed vessel pressurised reactions, which makes the workstation the most flexible and reliable available anywhere in the market for microwave chemical research. Nuwav-promaster has an intelligent icon based operation system and 7-inch high resolution touchscreen control, which is very simple and user friendly. The system can not only adapt to various chemical reactions but also create a combined effect in comparison to a single energy source in the field of synthesis and extraction. The product is equipped with the condensation, reflux, fluid replacement and inert gas purging interfaces. Regardless of organic reaction, synthesis, extraction, pharmaceutical research, protein chemistry, novel material science, polymer synthesis and many other fields. Nuwav-promaster will provide various possibilities and feasibility in the field of microwave chemical research. Microwave automatic frequency conversion and control, dual temperature control technology (contact-less ir and pt) can ensure the accurate recording and representation of temperature for each reaction. 7 inch high resolution touchscreen, intelligent icon based software with graphical representation of processes and reaction process videography facility. 316l stainless steel cavity and outer body ensure that all kinds of chemical reaction process smoothly.

laboratory reactors

Get Price Quote

The Series 5500 reactors are based on the popular 4560 and 4590 line of Mini and Micro Reactors. A redesigned compact magnetic drive, stirrer motor, and aluminum block heater that also serves as the stand keep the size and costs down. These systems will interest not only the the user with limited space or budget, but also the user looking to build a cost-effective multiple reactor system for combinatorial chemistry or high throughput investigations.

Microwave Synthesizer

Get Price Quote

Laboratory Glass Reactors

125,000 - 499,999 Per Piece

1 Piece (MOQ)

hydrogenator

Get Price Quote

We hold expertise in manufacturing, supplying and exporting the Hydrogenator. We also offer Coded Gas Liquid Reactors and Hydrogenator having efficient impellers and agitators for gas liquid reactions. Through our designs, we ensure that during rotation of the impeller, a vacuum is created at the tip due to Venturi action. This vacuum overcomes the liquid head. Fresh or unreacted gases from the vessel upper crest re-circulate into the liquid/slurry through the hollow shaft. Higher gas flow rates and finer bubbles sizes impart a very high gas-liquid interfacial area. A unique flow pattern provides desired movement of the catalyst and excellent contact of the gases with the catalyst or solids. The impellers of Hydrogenator are suitable for reactions like Hydrogenation Chlorination Oxidation Ammonolusis Ethoxylation Carbonation Phosgenation Bromination Sulphonation Flurorination

Liberty Lite Microwave Peptide Synthesizer

Get Price Quote

The Liberty Lite provides advantages over existing peptide synthesizers with it’s patented use of microwave irradiation during both the deprotection and coupling steps (15 minute cycle times), in situ temperature control, Flex-Add delivery system, and efficient solvent usage. Additionally, the system can be upgraded at any time to a complete Liberty Blue system. lex-Add Technology In-Situ Fiber Optic Temperature Control The Microwave Advantage The best software The Control software makes programming and running the Liberty Lite system fast and easy. • Pre-programmed default methods for the full synthesis scale range • Easy-to-use “Change Bottle” feature for rapid system setup • Usage and reagent calculators make reagent preparation simple • Fully customizable methods and cycles • Self-diagnostics and automated cleaning routines

hydrogenators

130,000 Per Piece

1 Piece(s) (MOQ)

Hydrogenators are specially designed for various gas-liquid reactions. These vessels are built for longer life and to withstand constantly varying temperatures and pressure due to internal reaction condition. These gas induction reactors are fitted with specially designed agitator which creates very high gas-liquid contact area by recirculation of headspace gases, leading to superior mass transfer rates. Agitator is available with two sealing options such as mechanical seal & magnetic drive. Manufacture as per client’s requirement and specifications. Material of Construction Offered in Stainless Steel 304, 304 L, 316, 316 L, 317 L, 904 L or Mild Steel, Carbon Steel material or special grade as inquired buy Client. Capacity Available in the ranging form 50 Litres to 30,000 Litres. Agitator design to suit the reactants viscosity and density. Stirrer Types: Anchor shaft, propeller, paddle, turbine will be available.

Microwave Synthesizer

297,000 - 350,000 Per Piece

1 Set (MOQ)

shaker hydrogenator

Get Price Quote

Used mainly for synthesizing or modifying organic compounds by catalytic hydrogenation. Used to study catalyst activity. Available from 100 ml to 2 liters capacity in glass & metal interchangeable vessels. Maximum pressure of 20 bar (300 psi) for metal vessel & 3 bar (45 psi) for glass vessel Charging, operating etc. is very simple, also vigorous mixing reduces the reaction time considerably. Very small & compact system without gland hence requires minimum spares & maintenance. Very economical considering the interchangeability of different capacity vessels in one unit.

Thermoreactor

Get Price Quote

Laboratory Glass Reactors

Get Price Quote

We are offering laboratory glass reactors. catering to the needs of the client, we offer laboratory glass reactors to the clients. We employ cutting edge technology for the manufacturing of our laboratory glass reactors. The laboratory glass reactors are tested on different parameters to ascertain their flawless quality. Moreover, we can offer the laboratory glass reactor in bulk quantities, as desired by the clients. Owing to these efforts, we have become a prominent laboratory glass reactors manufacturer and supplier. why our laboratory glass reactors? chemical resistantwell-designeddurable resistance to cracks click here for more details

Discover Microwave Synthesizer

Get Price Quote

Sterile Area Reactor

500,000 - 8,000,000 Per Nos

Laboratory Reactor

Get Price Quote

We are one of the well reputed Laboratory Reactor Manufacturers and Exporters. The Laboratory Reactor offered by us can be customized as per the needs of the clients. Our Laboratory Reactor is manufactured using high-grade components and technologically advanced machinery. The Laboratory Reactor is suitable for vacuum operation and can be availed at pocket friendly prices from us. Consists of : Stand system Laboratory stirring unit EUROSTAR power control-visc P7 with high torque Anchor stirrer LR 2000.11 with flow borings Safety shutdown Reactor cover In the free connections of the reactor cover a dispersing unit (ULTRA-TURRAX®), temperature sensors, flow breakers and other equipment can be installed. Features : Seals in contact with the product are made of solvent- resp. temperature-resistant perfluoroelastomer (FFPM). Infinitely adjustable speed. Integrated torque trend display for the measurement of viscosity changes. Through control actuated by microprocessor the set speed is held constant, even under load.Single-walled or double-walled vessels made from Borosilicate glass or Stainless Steel are available, each with or without bottom discharge valveLR-2.ST with double walled reactor vessel LR 2000.1 Laboratory Reactor Is Used For : Chemical reaction, mixing, dispersing, and homogenization processes on a lab scale. Production of crèmes and lotionsGrinding and disintegrating of solids and fibers in liquids or polymers. Download

hydrogenator

Get Price Quote

Hydrogenator offered by us utilizes a unique self gas inducing type multiple impeller system. The gas in the head space is induced inside the liquid by creating vortex due to top axial flow impellers (high solidity ratio hydrofoil impeller) and narrow baffles in that region. The feed gas being sparged through a sparger at bottom and the head space gas brought down by vortexing are, dispersed in fine bubble form by a radial hydrofoil impeller (hollow parabolic blade) installed at bottom.

Microwave Synthesizer

Get Price Quote

Microwave synthesizer can meet various experiment condition, User-friendly, ease to use design. Widely used in research such as Organic Synthesis, Pharmaceutical Chemistry, Organic Extraction, Food Science, Analytical Chemistry, Inorganic Chemistry, Protein Chemistry research, Material Chemistry, Etc. NuWav-Uno is a versatile reaction workstation that is superior to regular heating technique. The system has two different types of sensor Pt and Contact-less IR sensor which fulfil all your reaction requirement. The system is safe, convenient and reliable to be operated in any environment that is full of Organic Solvent.

Microwave Synthesizer

Get Price Quote

Microwave Synthesizer

600,000 - 1,500,000 Per Piece

We have microwave synthesiser with number of models. Best in results.