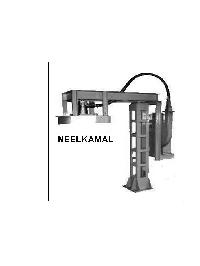

Ladle Preheater

Get Price Quote

We design Ladle Preheaters of both horizontal and vertical designs as per the requirements of the clients. Our Ladle Preheater has earned a name for itself owing to its flexible ladle heating. This Ladle Preheater of ours reduces the production cost because of being energy saving and having faster rate of heating. Features Oil fired Gas fired Easy operation Low maintenance Why Buy Our Ladle Preheater? Pocket friendly Flexible heating Faster heating Consumes very lower energy

Ladle Preheater

50,000 Per Set

Completely indigenised components High pressure - no back pressure no smoke- ladle completely closed by lid Gas train for gas control Stainless steel lid with ceramic module lining Motorised/hydraulic up down, tilting, swinging motion High heat resistant burner Temperature measurement & control Nozzle, Electrode etc. easily cleaned Continuous flame monitoring Auto Ignition Fully automated unit PLC control (optional) Innovations Ladle Drying and Preheating. Ladle Preheating Systems are custom designed and manufactured by Dhanaprakash. More than 250 installations in India and abroad. Any Ladle, Any Fuel, Any Position, Any Metal - PLC programmable systems. Quick, Smokeless, Energy Efficient. Recipient of G S Parkhe Award of MCCI in 1997. Concept Ladle completely covered by insulated Lid - No Heat Loss. Ladle bottom temperature is Higher than top. Auto Ignition, Fuel & Air on/off, temperature sensor for control. Instant preheating to 10000C. Waste Heat Recuperator preheats Combustion Air. All ladles of foundry single Preheater. Motions, Air, Fuel supply automated with interlocks. Single fuel or Dual fuel.

Best Deals from Ladle Preheater

Ladle Preheater

Get Price Quote

Ladle preheater ALL models wieght are Small model 25 kg-50 kg.Universal model 100 kg – 2000 kg.Big model 2000 kg – 10000 kg.Ladle Pre-Heaters this are more power heaters.

Ladle Preheating System

Get Price Quote

If you are not aware with what ladle pre heater is? It is used for heating refractory linings of lip-pouring and bottom-pouring ladles. We, super combustion technologies are one of the biggest manufacturers, suppliers, and exporters of ladle pre heater. This rugged constructed pre heater is very convenient for usage as well as easy to maintain. We manufacture highly efficient machines which saves a lot of your money. We know your demands vary, therefore our range of available sizes of this machine. No matter where you live in the world, we can export it very easily to you. All you have to do is tell us your requirements through our enquiry form or by placing a call.

Ladle Preheater

800,000 - 2,500,000 Per Piece

INDAID an ISO 9001:2015 certified Company manufactures Laddle Pre-heaters upto 25 Tons capacity for Foundry and Steel Plant applications. Both Horizontal and Vertical Laddle Pre-heaters are offered and the equipment is tailor made to suit individual laddle capacities. The fuel used may be Oil or Gas. The preheaters use energy efficient burners and are Ceramic Fibre Modular Lined for maximum energy efficiency.

Ladle Preheater

Get Price Quote

Ladle Preheater : Ladle preheater find application in heating refractory linings of bottom pouring and lip pouring ladles Available in Diesel, LPG, gas fired options. Salient feature: Saves fuel and time by ensuring ladle lining is ready to receive molten metal. Improves metal quality by reducing heat losses from metal.

Ladle Pre Heater

Get Price Quote

We are offering ladle pre heater jkfe manufactures ladle pre heater, is most effective and utilize maximum heat generated by burner. Machine can be provided in vertical as well as horizontal design. Machine for size up to 70 ton ladle can be supplied. cost- effective and rigid design less fuel consumption maximum utilization of heat generated by burner.

Fixed Ladle Pre Heater

150,000 - 300,000 Per Piece

1 Piece (MOQ)

Ladle Preheater

100,000 - 200,000 Per Piece

1 Piece (MOQ)

premium cyclone vertical preheater

1,250,000 Per Set

1 Set (MOQ)

Laddle Pre-Heaters

Get Price Quote

The pre heaters that we offer are high on parameters such as quality, durability and cost effectiveness. These are fabricated from high grade raw material such as steel and iron, which also ensures a longer service life. This heat treatment equipment is used mainly to preheat material, before it is utilized in any other process.The pre heaters are available in a variety of sizes and are extremely easy to operate

Horizontal Ladle Pre-heater

Get Price Quote

The horizontal heating position of ladle is mainly used for preheating and keeping the ladle warm, after or before changing and cleaning of the slide gate. Especially here the proper sealing of the ladle mouth is done by means of the specially designed trolley mounted vertical lid. In, horizontal preheaters the lid sizes and shape shall change as per the ladle opening. Heating stations are designed for single or various heating positions (e.g. The preheater is trolley mounted type) On request the preheater can be equipped with an additional door in the ladle cover for an oxygen purging lance. Depending on the conditions on site, the unit can be designed for travelling on rails. The movement can be effected pneumatically or electro-mechanical.

Ladle Preheating System

Get Price Quote

We Design, Develop & Manufacture Ladle Heating Systems for various applications. These systems can be energized by LDOLPGHFOCOKE OVEN GASOXY FUEL Oil Consumption - 5-7 Litres Ton of LML (Liquid Metal Level) Oil Consumption - 3 Litres Ton of LML (Liquid Metal Level) Short flame length leads to uneven heating across the ladle leaving a cold zone at the bottom Long & lazy flame leads to uniform heating across the Ladle length eliminating chances of any cold zone in the Ladle Slower Heating Faster and Uniform Heating Lining made of CASTABLE

Vertical Ladle Preheater

40,000 Per Piece

1 Piece (MOQ)

Ladle Preheating System

Get Price Quote

In a typical heating application of ladles in steel plants ENCON film burners can save as much as 50-60% of fuel. The ladle heating time has been reduced substantially and a specific fuel consumption of about 3-3.5 liters per tonne of ladle capacity has been achieved.

Ladle Preheater

Get Price Quote

Ladle Preheater

350,000 Per Piece

Foundry Ladle Preheater

100,000 Per Piece

Ladle Pre Heater

Get Price Quote

1 Set(s) (MOQ)

We are offering ladle pre heater. Salient features : easy to operate fuel : lpg diesel kerosene efficient sturdy design

Ladle Pre Heater

Get Price Quote

Ladle Preheaters are used to heat refractory lining of various sizes of Lu: and Bottom Pouring Ladles.A cowl lined with high grade refractory ramming mass is fitted on one end of the horizontal frame and the combustion air blower is mounted on the opposite end of the horizontal frame.The Ladle Preheater is fitted with a high air pressure atomizing type oil burner with sensitrol oil valve to obtain maximum drying temperature of I 000 Deg. C. The burner is fitted vertically down at the centre of the cowl. The horizontal frame can be swivelled manually on the vertical axis and locked in position ass desired. The Blower Motor is totally enclosed fan cooled suitable for 400/440 Waits, 3 Phase, 50 Cycles A.C supply.