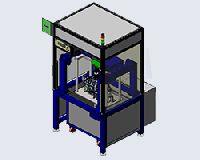

Leak Test Equipment (DeltaTM3)

Get Price Quote

Item Code : DeltaTM3 DELTA TM3 pneumatic modules are the ultimate achievement in traditional leak testing with absolute pressure decay measurement. They are the best solution for any who wish to integrate a reliable and compact testing station in automated systems. The absence of any button or display allowed for a smaller footprint, making it possible to fit this equipment in any facility, as close as possible to the test piece, minimising superfluous volumes and achieving a higher speed and sensitivity during tests. DELTA TM3 directly manage the test timing and pressure, the user only needs to provide compressed air. DELTA TM3 pneumatic modules can be connected to and controlled by any PLC using only a digital output for start the test and two digital input to read the result, passed or rejected, of the test. Further more with the RS485 serial line with ModBus protocol any PC, PLC or HMI terminal is able to display and set all the test data and parameters. Main features of DELTA TM3 are : Many different fullscale ranges: -0.9 / 2 / 6 / 10 / 20 Resolution of 1 Pa for models up to 6 bar and 10 Pa for models up to 20 bar Reliable pneumatic circuit, complete with valves and transducer 99 test tables Calculation of leak in cc/min or cc/h based on the volume of tested product Digital interface for PLC RS485/USB communication interfaces for PC, PLC o HMI Virtual Instrument (driver) for National Instrument LabView available

Marine Diesel Engine Analyzer

275,000 Per Piece

Best Deals from Leak Test Equipment

Leak & Pressure Test Connector

18,000 Per Piece

1 Piece (MOQ)

Sealant Enterprises is the best manufacturer and supplier of leakage and pressure testing coupling. In the medical manufacturing industry, reliable quality testing is of the utmost importance particularly when it comes to leak testing. An accurate and reliable leak test starts with leak test seals and connectors you can trust. Leaking seals are the primary cause of misleading leak test results, especially in pneumatic test environments. When testing medical devices for leaks, there are specific test requirements that should be included in your leak test environment. For example, you will need leak test seals and possibly part holding fixtures built to secure hard-to-seal fittings, such as fittings for flexible tubing and lure connectors. You also want to test products in which all touch points are made of stainless steel, urethane, and silicone-based sealing materials to ensure Food and Drug Administration (FDA) compliance. It is important to understand the specific design, fixture, and seal considerations for medical device manufacturing and leak testing, which we will review below. Test Station Design Considerations for Medical Device Leak Testing Before you can build an efficient leak test station, you need to start with a plan that considers the following: Automated vs. Manual Part Handling Whether you are using automated part handling, manual testing, or a mixture of both, you need to allow sufficient cycle time for an accurate test. With an automatic leak test, the system automatically senses the part and then connects with sufficient seal force to hold the part in place when test pressure or vacuum is applied. You can then start the test. When you conduct the test manually with Leakage and pressure Test Couplings, you need to account for variables that may affect the results: Is the sealing/locking force sufficient to hold the part in place for an accurate test? What kind of operator movement do you need to incorporate into each manually activated seal or clamp? How efficiently can the operator conduct manual load/unload of the parts for the leak tests? Line Configuration Line configuration is also an important consideration. The line setup will determine where to place your tooling and whether it is a lean cell design, single-piece flow design, or batch testing setup. Choose to deal with us and get the best Leakage and pressure Test Couplings from us.

MELD-4000-P Dry Air Leak Testing Machine

Get Price Quote

The Major Features and Benefits of these instruments are Fully programmable test pressure limits, allowable leak rate, test cycle times to suit individual application. Short testing time. Low investment and running cost. Objective and quantified statement of quality with GO-NO GO results. Sufficient accuracy. User friendly and fully automatic machine with/ without pneumatic/ hydraulic fixtures can be provided. Features Process counter and statistical calculations. Remote computer controlled programming and execution. Statistical process control software for use on PC. Bi- directional Interface to communicate with other devices Interface with machine control and highways. Customized Manual/ Pneumatic or hydraulic Clamping/Sealing Test fixtures. AutomotiveAir Brake Circuit, Ball Valve Casing, Bellows Seal, Brake Accumulator, Brake Circuit, Brake fluid reservoir, Brake master cylinder, Camshaft Cover, Castings, Clutch Master, Clutch Housing, Cylinder Block, Differential, Engine Block, Engine Combustion Chamber, Engine Cover, Exhaust Manifold, Exhaust Pipe, Fuel float, Fuel injector, Fuel Nozzle, Gear Box Housing, Heater Core, High and Low Pressure fuel Circuit, Injection fuel circuit, Intake manifold, Intake Valve, Manual Transmission, Muffler Oil Circuit, Oil Heater, Oil Manifold, Piston, Power Steering Reservoir, Pump Housing, Silencer, Shock Absorber, Hydraulic, Spiral wound gaskets for camshaft, Camshaft, Cylinder Head, Engine, Steering Box( Hydraulic), Supercharger, Tank Fluid Circuit, Throttle Body, Transfer Case, Turbo Compressor, Washer Fluid reservoir.Automotive ComponentsAir Filter, Battery, Carburetor, Catalytic Converter, Diesel Filter, Diesel Injector, Flow Control Valve, Fuel Cap, Fuel Filter, Fuel Gauge, Fuel Pump, Fuel Tank, Gas tank, Gear Box, Heat Exchange, Horn, Hydraulic Pump, Oil Cooler, Oil Filter, Oil Gauge, Oil Pressure Switch, Oil Pump, Power Steering Pump, Pressure Relief Valve, Pneumatic Spring, Radiator, Rubber Hose, Shock Absorber, Spark Plug, Tank, Fuse Box, Fuel Circuit, Thermostat, Vacuum Solenoid, Water Fluid Pump, Water PumpEngineeringValves, Seated Assemblies, Pumps, Hydraulic Systems, Refrigerant Systems, Castings, Heat Exchangers, Radiators, Aerosol CansFood and PharmaceuticalsPacking Tins, Bottles, Plastic Jars, Cookers, Boilers, Vacuum Flasks, Aerosol Cans, ContainersCustomizationWe can develop complete turnkey leak test solutions for your applications using our engineering expertise in application of leak detection techniques, Design of Electrical and Electronics circuitry, Pneumatic and Hydraulic Clamping/ Sealing Fixtures/ PLC based programmable loading and Unloading Systems

Leak Test Equipment

50,000 - 55,000 Per Piece

1 Piece (MOQ)

Time Control. 59 min: 59 sec Vacuum. Adjustable up to 550mmHg Keyboard. 4 soft touch keys Audio Alarm Yes Desiccator 8" ,10" or 12" Vacuum Pump Oil free Pump, MV27" $5%,1/4HP Motor Test Unit size (400 ×345 x200)mm

Wet And Dry Leak Testing Machine

Get Price Quote

1 Piece (MOQ)

Technical Specifications • Single or Multiple •Pressure range 0-16 bar air •Structure MS powder coated / painted •Tank SS or Glass •Testing medium : Air •Analogue Gauges or digital gauges available •Usually for casting bodies for leakage test •Dry and water dip both •Water dip leakages visually seen •Test done also using high accuracy leak testers

Leak Test Equipment

Get Price Quote

dry leak testing machine

Get Price Quote

The Leak testing machine gives correct data outputs for SPC analysis. The Leak testing machines also have automatic passfail markings. Vimal Industrial systems combines standard leak test instruments with specially designed fixtures and sealing mechanisms in its Leak Testing machine. Do contact us for any information on Leak Testing machines.

Food Leak Tester

Get Price Quote

The MODEL 9001HP Leak Tester allows beverage ends to be tested for leaks in the score and tab area. The MODEL 9001LP Leak & Buckling Tester is used to determine the buckling resistance of food/utility ends and to test for the presence of leaks in food/utility ends.OperationAn appropriate set of Change Parts, determined by the type and size of a sample being tested, are installed on the unit. Two ends are placed in the Change Parts and sufficent pressure is applied to either buckle or pass/fail the ends. The water-filled chamber will also reveal leaks in the ends under test when pressure or vacuum is applied.Change PartsThis unit requires the use of Change Parts.The 9001HP uses 9837 Change Part.The 9001LP uses any of the following Change Parts: 9748 ; 9749 ; 9750 ; and 9751.Features GOOD VISIBILITY OF ENDS IN TEST REVEALS SMALL LEAKS LIGHTING HI-LIGHTS LEAKS TESTS UNDER PRESSURE AND VACUUM TESTS TWO ENDS AT A TIME SEPARATE GAUGE FOR EACH END LAZY HAND INDICATORS WIDE RANGE OF ROUND AND NON-ROUND CHANGE PARTS

Bag Leak Check Machine

Get Price Quote

dry leak testing machine

200,000 Per Piece

1 Piece (MOQ)

Leak Test Equipment

399,000 - 400,000 Per Piece

dry leak testing machines

Get Price Quote

Differential Sensor Based Leak Testing Machine to meesure pressure drop up to 0.1 Pascal. These machines are multi channel to test various chambers at different pressures and reject levels.Fully automatic Quality control machines for proper traceability. These machines are based on Pressure Decay Method. These machines consist of pressurizing the system with a defined pressure gas, usually dry air. Then the part is isolated from the gas supply and, after a stabilizing period, its internal pressure is monitored over time. The pressure drop is measured in the time. If the pressure in the system drops fast, there is a large leak present in that component or section of the system. If the system’s pressure drops slowly, there is a small leak present. If the pressure remains the same, that component is leak-free. The leak rate can easily be computed considering the volume of the component.Advantages of these machines are: Fastest, most consistent test technique for 90+% components. Non-Operator Dependant and test data can be collected by printer or computer. Passed product can be automatically marked (ink, stamping, and engraving) to insure parts are tested prior to subsequent processes. No cleaning/drying operations required after testing. System accuracy immune to most environmental conditions. p;Can be configured for 100% testing downstream of most bonding operations

Leak Test Equipment

Get Price Quote

We at SYSCON strive to give the best possible support solution to our customers. Air Leak Testing is a highly specialized field and Air Leak Testing Systems involve customization. Today SYSCON bring expertise and technology from Ms Fukuda Company Limited, Japan, who are world leaders in Air Leak Testing and Flow Measurement Systems. Name any automobile part like, Engine Blocks, Engine Heads, Cover Cylinders, Shock Absorbers, Engine Valves, Gear Boxes, Power Steering, Oil Filters, Oil Pans, Manifold, Crank Cases, Fuel Parts, Mufflers, Batteries, Cooling Systems, electrical Parts, Brake Parts, Boosters, Air-conditioning parts, Engine Assembly, Cast Products and Non-Automotive products like Cans, Tins and many more;

dry leak testing machine

Get Price Quote

Leakage Test Rig For Fuel Tanks Of Cars, Two Wheelers, Tractors (water Immersion Method) Leak Testing Machine For Plastic Fuel Tank, Oil Tank, Washer Wind Shield Etc. (pressure Decay Method) Leakage Testing machine Dry type For Silencer, Muffler, Catalytic Converter Etc. (pressure Decay Method) Leak Testing Machine For Radiators Leakage Test Rig wet type For Axle Housing (water Immersion Method) Leakage Test Rig For Valve Seat of Cylinder Head (pressure Decay Method) Leak Testing Machine For Cylinder Head Water Gallery Leakage Test Rig For Exhaust Pipes Leakage Test Rig For Two Wheeler Filters Leakage Test Rig For Any Other Automobile Component

Leak Test Equipment

89,600 Per Piece

dry leak testing machine

Get Price Quote

Dry leak testing machine, These machines are highly efficient and needs low voltage consumption. Our skilled workforce use high end technologies and modern machines while manufacturing these machines This types machines are generally used for the detect the exact position of leak under water. It is automatic function that after each & every NOK component it will take the component inside the water & fill the air for visual inspection of leak.

dry leak testing machine

Get Price Quote

Component Testing Can Be Done On Dry Mode.Auto Manual Function (PLC Compatible).Micro-Porosity Detect Sensor "ATEQ" Make-France.Automanual punch marking for “OK” component.Excellent illumination system in water.Fixture changing facility for various type for component.

leak testing equipment

Get Price Quote

Description :-Leak testing equipment refers to a class of nondestructive testing equipment commonly used to measure the escape of liquids, vacuum or gases from sealed components or systems. There are some arrangement of leak testing equipment that require a separate sensor or leak detector as an input. These devices are often equipped with various other components such as calibrators, gauges, pumps and cases.Application :These equipment find a wide application in the following areas: Research & Development System Manufacturing Furnace/Metallurgy Refrigeration Manufacturing Air Conditioning Manufacturing Chemical Industry Analytical Requirements Automotive Component Industry Oil & Gas Plants

Leak Test Equipment

Get Price Quote

Armed with the latest designing tools ACSPL will study the feasibility of the application preferably and guide the user throughout the applicability. The user can have hands on experience of the final product.

Leak Test Equipment

Get Price Quote

This Leak Test Machine is of superior quality and known for its high-performance, durable construction, reliability, low maintenance need, hassle-free performance and long running life. We check our manufactured product at our in-house manufacturing facility by following all industry guidelines to deliver a feature-rich product to our clients.

dry leak testing machine

Get Price Quote

We manufacturer high quality Leak Testing Machines to suit various leak testing applications in production testing, quality control and r & d applications. This is programme based Micro Controller Machine capable of easy and accurate volume leak testing down to 1 cc min and measuring test pressures over a range from vacuum to 200 bar using dry air as a source. It can test the products for leakage as per the latest standards.

dry leak testing machine

Get Price Quote

The Dry Leak testing machines are used to leak test components for porosity or leakage due to any damage. The medium for the test is air.The testing is done using a pressure decay method with a specified test pressure and an allowable leak rate. The interfacing of the machine and controls is done with an imported indigenous leak detection instrument, The photograph shows a dry leak testing machine for a four cylinder head. Cylinder blocks, brake system components, or any similar components can be checked using this method.

leak testing equipment

Get Price Quote

Description :-Leak testing equipment refers to a class of nondestructive testing equipment commonly used to measure the escape of liquids, vacuum or gases from sealed components or systems. There are some arrangement of leak testing equipment that require a separate sensor or leak detector as an input. These devices are often equipped with various other components such as calibrators, gauges, pumps and cases.Application :These equipment find a wide application in the following areas: Research & Development System Manufacturing Furnace/Metallurgy Refrigeration Manufacturing Air Conditioning Manufacturing Chemical Industry Analytical Requirements Automotive Component Industry Oil & Gas Plants

dry leak testing machine

Get Price Quote

A hydraulic press is used for lifting or compressing large items. Hydraulic mechanism is used to generate the force which increase the power of a standard mechanical level. Hydraulic presses are widely used in a manufacturing environment. We offer Hydraulic Press-C-frame, H-Frame -4-Pillar,2 piller which have precision grounding base plate with diagonal T-slots. Developed in compliance with international quality standards, the heavy-duty H-frame of the press enables high force applications. Due to re-tooling time, the hydro pneumatic becomes flexible and delivers consistent performance in given environment. We also offer customization on our range as per the specifications of clients.

high pressure leak test machine

150,000 Per Piece

Leak Test Equipment

350,000 Per unit

Leak Test Equipment

Get Price Quote

Presto’s Vacuum Leak Tester purposely complies with various national and international quality standards. The testing instrument is used to analyze visually the consistency of the foiled cups when kept under vacuum. To perform the vacuum leak test, a definite amount of vacuum is created inside the chamber to evaluate the integrity for the purpose of the leak proof of the foil packaging. The test is done to assure that the seals are unbroken and perfectly fine. It is a test procedure which is performed before transporting the product for warehousing or storage.

RADIATOR WET LEAK AIR TEST Cabinet

Get Price Quote

FEATURES: Stainless steel Test Cabinet with top open cover with rigid clamps and transparent poly carbonate sheet for test visualization Pressure regulators for adjustment of air test pressure and hydro test pressure Solenoid operated valves for air and water application Safety interlock for releasing pressure from test component when emergency push button is pressed Tower light indication for status of test . Green light when system is without pressure. Red light when component is under pressure. High Precision Pressure Sensor for feedback and display. Pneumatic cylinder for dipping the test component inside water and taking out of water when test is over ( holding time completed ) Air operated pump for hydro burst test with water fluid Push Buttons for initiation of leak , burst test and up-down movement of test components.

Leak Test Equipment

Get Price Quote

Leak Test Equipment, automation machine, Plc, Industrial Automation Systems