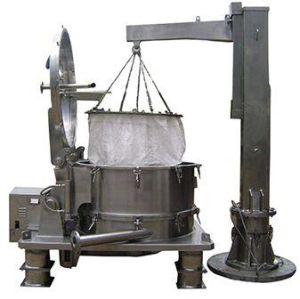

Three Point Lifting Bag Centrifuge Machine

135,000 Per Piece

1 Piece (MOQ)

Four Point Bag Lifting Centrifuge Machine

Get Price Quote

We hold specialization in providing a broad range of Bag Lifting Centrifuge Machine to the patrons. These heavy-duty centrifuges are manufactured using supreme quality raw material, which is obtained from certified vendors of the market. The dehydrated solid can be easily discharged by the filter bag situated at bottom. We are looking for queries from all over India.

Best Deals from Lifting Bag Centrifuge Machine

Bag lifting Type Centrifuge

Get Price Quote

Bag Lifting Type Centrifuges are basically upgraded form of Manual Top Discharge Centrifuges. These machines have lip detachable from the basket which helps in easy removal of filter bag with solid material from outside the basket. The time required for cake removal in bag lifting type centrifuge Machines is very negligible & also Manual contact with cake is minimised. The lifting of bag/cake is carried out by means of cGMP Hydraulic Lifting Device which eliminates usage of chain pulley lifting mechanism, thereby preventing product contamination Special Characteristics of our Bag Lifting Type Centrifuges Instant discharge / unloading of cake by means of hydraulic lifting device Comparatively increased of production due to reduced batch time. Cake spillage / Loss will is negligible Cleaning or changing of filter cloth outside centrifuge Reduced Human contact. Fully opening of Lid gives/ Ensures more space for better cleaning Sturdy design & construction as per cGMP norms. Four point suspension type which requires negligible Foundation Centrifuge manufactured as per international standards with inertia platform & AntiVibration mounts to ensure smooth operation. Vapour Tight Arrangement Nitrogen purging system for Basket & bearing housing/ casing Safety Device such as Zero Speed Lock for the Centrifuge cover. Full validation services available including DQ, IQ/OQ, FAT / SAT protocols. cGMP construction for Pharmaceutical Models. Kilolab Model to Production Models available Enhanced/ Optional Features of our Bag Lifting Type Centrifuges : Fully opening Outer case/ Body with CIP cleaning for better cleaning/ accessibility and validation purpose for special pharmaceutical process application Variable Frequency Drive with the Dynamic Braking System Cake thickness monitor system. Excess Vibration Monitoring & Tripping system Fluid Coupling High Speed RPM for Basket for special application

Four Point Suspended Lifting Bag Type Centrifuge

Get Price Quote

Leveraging on our vast infrastructure facility, we are capable of manufacturing, supplying and exporting Four Point Suspended Centrifuges. Manufactured under the strict supervision of expert professionals, these products are stringently checked on various parameters to ensure flawlessness. We also have R&D experts, who conduct regular surveys and researches for improvising our existing range of products. With the help of our wide distribution network, we are able to deliver these Four Point Suspended Centrifuges at clients premises within the set time frame. Features: • High production capacity• Longer functional life• Easy to maintain and install Additional Details :• Increases the production capacity• Help in uniform distribution of slurry• Bearing housing support C.I. with SS lining provision• Help in quick and easy loading/unloading operations• Robust construction support• Provide smooth running and rapid acceleration• Supported by the necessary belt drive

Lifting Bag Centrifuge Machine

Get Price Quote

Hydraulic rescue tools are used by emergency rescue personnel to assist vehicle extrication of crash victims, as well as other rescues from small spaces. These tools include cutters, spreaders, and rams. Hydraulic rescue tools are powered by a hydraulic pump, which can be hand, foot, or engine-powered or even built into the tool. These tools may be either single-acting, where hydraulic pressure will only move the cylinder in one direction, or dual-acting, in which hydraulic pressure is used to both open and close the hydraulic cylinder. Previously rescuers often used circular saws for vehicle extrication, but these suffered from several drawbacks. Saws can conduct sparks, which could start a fire, create loud sounds, stress the victim, and often cut slowly. Alternatively, rescuers could try to pry open the vehicle doors with a crowbar, which, at times, could compromise the stability of the vehicle, injure the victims further, or inadvertently trigger the airbags of the vehicle.

Bag Lifting Type Centrifuge Machine

200,000 Per Piece

Suspension / MountingAll the bottom driven basket centrifuges can be supplied either in 3 point type suspension or the newer 4 point type mounting (on VISCO Damper / Sordino Damper) anti vibration mounts.Material of constructionCarbon Steel, Stainless Steel, Hastalloy, Rubber Lined, Fluoro Polymer Coatings like Halar (ECTFE), PVDF (ETFE ), Teflon (PFA) etc. Lining / Coating can be provided on the contact parts as well as on the exterior body for prevention from spillage and corrosive atmosphere.Advantages of 4 Point Mounting Level of vibration is much lower & operates very smoothly. Can be mounted on upper floor and can be easily relocated. Almost negligible maintenance cost. Working area is free from abstracts and a clean area can be maintained. Types / Models of Basket Centrifuges Pilot Plant Centrifuge Bottom Driven Top Discharge Type Centrifuge Bag Lifting Type Centrifuge Bottom Discharge Type Centrifuge with/without Scrapper Top Driven Bottom Discharge Centrifuge Additional Features (Optional) Residual Heel (Cake Removal System) Cleaning in Place (CIP) Leak Test as per DIN 24 400 Nitrogen Blanking System Speed Indication with Zero Speed Switch Automation Cake Sensor

Lifting Bag Centrifuge Machine

Get Price Quote

Bag lifting Type Centrifuge

Get Price Quote

DESCRIPTION: Introducing the four suspension Bag lifting Type Centrifuge Machine is modified to detach and lift the Top-capring of the basket along with filter bag, attached to it. The center opening of the filter bag allow the filterate solids, to be discharge of solids is easy and fast. ADVANTAGE : Flexible Cake Discharge Less manual labor involved Cake handling loss negligible Uniform distribution of slurry Uniform washing of cake No manual contact with cake/solid No Foundation Required Easy Relocate the Centrifuge Machine in the plant Quick Cleaning OPTIONS : Fully Opening Outercase CIP system Gas Tight Drice System (Belt & Pulleys) Zero Speed Interlock Charge regulator Vibration Tripper Vibration Monitoring System Nitrogen Purging Control System Hydralic lifting Device

Four Point Bag Lifting Centrifuge Machine

Get Price Quote

Lifting Bag Centrifuge Machine

Get Price Quote

This device meets with cGMP and dispenses with the need for an overhead hoist. This device was made of Carbon Steel and clad with Stainless Steel and can be placed next to the machine inside GMP area. With this we can eliminate chain & pulley mechanisms for lifting & prevents product contamination.

Bag lifting Type Centrifuge

Get Price Quote

Bag Lifting Type Centrifuge is the heavy duty centrifuges with fast acceleration and smooth running. After centrifuging process the solids are unloaded by lifting the basket top along with filter bag and solids. The filter bag is fitted with removal basket top with a bag holding ring. The ring holds the filter bag firmly while filtering and lifting. The bottom opening of the filter bag allows the drainage of solids so as to make the discharge of solids simple and swift. It involves least manual labor and facilitates for effortless loading and unloading along with superior production capacity per batch.Features : Easy and fast unloading. Reduction in batch time. Complete discharge of solids. Requires minimum manpower Cake spillage on the floor is minimal. Manual contact with cake is avoided Easy cleaning of the basket in and out More volumetric charge per machine available The time required for cake removal is negligible Full opening of the lid helps in easy maintenance Original Crystal Structure will remain intact as there is no scrapping. Application : Chemical industries Medicine manufacturing Dyes and chemical processing Bottom Driven Top Discharge Centrifuge is the most versatile & basic model of basket centrifuge for solid & liquid separation. After centrifugation, the solids are scrapped and removed manually from the top. The machine works with quick loading and unloading and possesses a hassle-free functional life. Featuring bottom driven top discharge provision, the presence of precision manufactured external body support along with interlock safety cover makes this centrifuge highly preferred. Features : Mechanical clutch pulley Standard 3 pendulum suspension Variable frequency drive (inverter) Inertia plate and anti vibration mounts (4 point mounting) Simple construction Low maintenance cost Suitable for sticky, hard and lumpy products Application : Centrifuges/Hydro Extractors are perfect for extraction of water/liquid in Pharmaceutical, Chemical, Textile Industries and ETP plants

Lifting Bag Centrifuge Machine

250 - 4,500 Per Pieces

Lifting Bag Centrifuge Machine, bucket filter, star filter bags

Lifting Bag Centrifuge Machine

Get Price Quote

Lifting Bag Centrifuge Machine, MS Limpeted Reactors, Batch Dryer

Lifting Bag Centrifuge Machine

Get Price Quote

Lifting Bag Centrifuge Machine, Curd Separator

Lifting Bag Centrifuge Machine

Get Price Quote

Lifting Bag Centrifuge Machine, Chemical Micro Pulverizer