Solid Liquid Extraction System

Get Price Quote

Uncover the transformative potential of Solid-Liquid Extraction with K-Jhil. Essential in various industries, this sophisticated process revolutionizes separation by efficiently isolating valuable components from solid matrices. Explore the principles and advantages of this technique, renowned for its precision and quality outcomes. At K-Jhil Scientific, we lead the charge in extraction technology, offering unparalleled capabilities through our Solid-Liquid Extraction Pilot Plant. Join us at the forefront of innovation and elevate your separation processes with K-Jhil’s expertise.Salient Features : Solid Matrix : The starting material is often a solid substance containing the desired component. Solvent : The liquid that selectively dissolves the solute from the solid matrix. The choice Of solvent is crucial for successful extraction. Solute : The target component that needs to be separated from the solid matrix Applications : Pharmaceuticals : Extraction of flavors, colors, and bioactive compounds from herbs, spices, and botanicals. Food and Beverage : Versatile applications in chemical processing for separation and purification. Environmental Remediation : Removal of contaminants from soil or water through selective extraction. Chemical Processing : Separation of valuable chemicals from industrial waste or by-products.

Liquid Extraction Plant

10 Per Piece

1 Piece (MOQ)

Features Density between phases Easy to install Reasonable price

Best Deals from Liquid Extraction Systems

liquid extraction systems

1,500,000 Per Piece

1 Piece (MOQ)

Liquid Extraction Columns

250,000 - 1,500,000 Per Piece

1 Piece (MOQ)

We are having Vital experience of Design, Installation & operation of Extraction Columns Following are the benefits to get Extraction Column designed & Purchased from us : To optimize the diameter and Height of packing to minimize capital cost. To Optimize the extraction liquid flow to reduce pumping and energy cost. Optimize the flow Concentration of solvent in lean phase to minimize energy cost.

Fully Automated Liquid Extraction System

Get Price Quote

10 pieces (MOQ)

liquid Extraction Unit

Get Price Quote

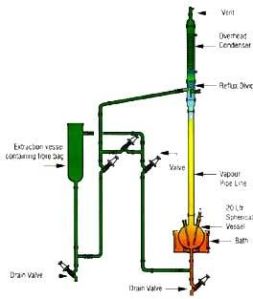

Liquid extraction, sometimes called solvent extraction, is the separation of constituents of a liquid solution by contact with another insoluble liquid. The unit described here is for a semi-batch operation. The liquid to be extracted is poured into an extraction vessel. Solvent is boiled in a reboiler vessel and condensed in an overhead condenser, the condensed liquid collected in a reflux divider and passed through pipework to the extraction vessel. The pipework incorporates valves in order that the solvent can enter the extraction vessel at either the base of the top, depending on the relative densities of the solvent and liquid to be extracted. The solvent and the extracted liquid pass back to the reboiler and the process is repeated until the extraction is complete. The extraction vessel is then drained and the solvent evaporated from the reboiler vessel and collected in the extraction vessel enables the two liquids to be drained from their respective vessels. The unit is available in vessel sizes of 10, 20, & 50L and is suitable for operation under atmospheric pressure.

Liquid Extraction Plant

Get Price Quote

Liquid-liquid extraction or solvent extraction is a separation process which is based on different distribution of the components to be separated between two liquid phases.

liquid Extraction Unit

Get Price Quote

10 Set(s) (MOQ)

We are offering liquid extraction unit. liquid extraction, sometimes called solvent extraction, is the separation of constituents of a liquid solution by contact with another insoluble liquid. The unit described here is for a semi-batch operation. the liquid to be extracted is poured into an extraction vessel. Solvent is boiled in a reboiler vessel and condensed in an overhead condenser, the condensed liquid collected in a reflux divider and passed through pipework to the extraction vessel. The pipework incorporates valves in order that the solvent can enter the extraction vessel at either the base of the top, depending on the relative densities of the solvent and liquid to be extracted. The solvent and the extracted liquid pass back to the reboiler and the process is repeated until the extraction is complete. The extraction vessel is then drained and the solvent evaporated from the reboiler vessel and collected in the extraction vessel enables the two liquids to be drained from their respective vessels. the unit is available in vessel sizes of 10, 20, & 50l and is suitable for operation under atmospheric pressure.

liquid extraction systems

Get Price Quote

Order Extraction System

Get Price Quote

Rufouz Hitek Engineers are highly specialized in the manufacturing of effective Extraction System to fulfill all your industrial requirements. It is highly advanced and most efficient method. We also design systems for such products which vapor pressure is usually same. Extraction normally has many additional steps as compared to others for recycling the solvent.

Liquid Extraction Plant

Get Price Quote

We are one of the trusted companies in India, which is manufacturer and exporter of Liquid Liquid Extraction unit. The unit we provide is based on latest technology, which is mechanically designed and tested by our engineers so that it can give the best of its performance. Our unit is fully customized to meet our client’s requirement.Features : Easy maintenance Sturdy structure Fine functionality Liquid extraction, sometimes called solvent extraction, is the separation of constituents of a liquid solution by contacting with another insoluble liquid. The unit described here is for a semi-batch operation.Process Description :The liquid to be extracted is poured into an extraction vessel. Solvent is boiled in a reboiler vessel and condensed in an overhead condenser, the pipework to the extraction vessel. The pipework incorporates valves in order that the solvent can enter the extraction vessel at either the base or the top, depending on the relative densities of the solvent and liquid to be extracted.The solvent and the extracted liquid pass back to the reboiler and the process is repeated until the extraction is complete. The extraction vessel is then drained and the solvent evaporated from the reboiler vessel and collected in the extraction vessel enabling the two liquids to be drained form their respective vessels.The units are available in vessel sizes of 10, 20, & 50 Ltr. and are suitable for operation under atmospheric pressure.

Liquid Extraction Plant

125,000 - 351,000 Per Piece

1 Set (MOQ)

UD Offers different Extraction solutions Mixer Settler Mixer-settlers, both as stand-alone and as in-column type, are offered for special applications. Due to the pump-mix turbine no additional feed pumps are required in most cases. Continuous Packed Bed Liquid Liquid Extraction The key benefit of a packed column is the high throughput which leads to small column diameters. Together with specially adapted liquid distributors, our structured packing provides the best extraction performance Agitated Extraction Column In applications with high mass transfer and/or changing physical properties, this is the column of choice. The compartment geometry can be adapted to compensate for changing conditions resulting in a constant high column performance. The main features are the special mixing turbines and the perforated partition plates. All Items can be coupled with Computers for Control and Data Acquisition through SCADA. UD Offers Glass Rotating Disc Extractors The Rotating Disc extractor is a continuous, counter-current, liquid-liquid extractor, used for extraction of product or impurities from aqueous or organic streams by extraction with suitable organic solvent or water. The technique with its excellent repeated mixing and settling feature at each stage creates an extraction capability that is equivalent of several washings in a batch kettle. Solvent consumption can be reduced almost to 50% and power consumption to 70% than the batch operation. Simple and non-laborious operation with use of simple automation makes it possible to get consistent results.Used for extraction of product or impurity from bulk drug reaction mass, impurity removal from agrochemical product streams, extraction of product from mass stream in plant extract stream, biochemicals, recovery of product or toxic component from waste water stream Agitated Extraction is Practically Universally Suitable for all type of Liquid Liuid Extraction.Limiting Condition is minimum density difference 0.05 Kg/M3 between both phases and a not to form Stong tendancy to form stable emulsion in order to allow a smooth agitation In applications with high mass transfer and/or changing physical properties, this is the column of choice. The compartment geometry can be adapted to compensate for changing conditions resulting in a constant high column performance. The main features are the special mixing turbines and the perforated partition plates. Advantages : Adaption of Compartment and Agitator Geometry to the specific Product and Operating Condition The Optimal Droplet Size can be adjusted ed by varying Agitation Speed Insensitive to Solids In applications with high mass transfer and/or changing physical properties, this is the column of choice. The compartment geometry can be adapted to compensate for changing conditions resulting in a constant high column performance. The main features are the special mixing turbines and the perforated partition plates.

Supercritical Fluid Extraction System

3,500,000 - 120,000,000 Per Unit

Salient Features Supercritical fluid extraction systems with pressures upto 700 bar for lab scale units & upto 450 bar for commercial plants Semi or fully automated PLC based plants with CO2 recycling PED, U stamp, CE, CSA, UL certification optional Customizable designs as per client requirements World-class technology for natural products There is a tremendous demand for high purity & residual solvent free extracts of natural products. Also there is increasing requirement of eco-friendly manufacturing processes for the extraction of natural products Supercritical fluid extraction technology provides an economical solution toproviding a safe & eco-friendly way for extraction of natural products. Its superiority over the conventional technologies of extraction, especially for natural products in the food and pharmaceutical industry is well recognized Supercritical CO2 textile dyeing is an emerging innovative waterless technology for dyeing of textile fabrics that will revive the textile industries Commercial Applications of SCFE extractor systems Extraction of natural products such as spice oil & oleoresins, flavors, fragrances, colors Decaffeination of tea & coffee Production of uniform &ultra fine particles Supercritical CO2 (SCO2) textile dyeing of fabrics Supercritical CO2 (SCO2) cleaning of high precision metal components Drying of aerogels Advantages of SCFE system Extract with delicacy & freshness close to natural High potency of active components Longer shelf life extracts Eco-friendly & green technology with no residual solvent & effluents High flexibility of process conditions Simultaneous fractionation of extracts High yields compared to solvent extracted products Low batch times for extraction Recycling of CO2 Low operating cost Advantage of CO2 as a solvent Carbon dioxide is generally regarded as safe (GRAS) for food products Inexpensive & easily available Non-toxic, non-flammable and inert to most materials Process description for lab-scale plants The Carbon dioxide gas from the cylinder is first liquefied & then pressurized above the critical pressure of CO2 (73.8 bar) to the required pressure necessary for extraction. This high pressure liquid CO2 is then heated above the critical temperature of CO2 (31 °C) to the required temperature. CO2 which is now in supercritical phase (SCCO2) enters the extractor where the raw material is fed in powder form & the extraction is achieved on the basis of solubility. The compounds dissolved in SCCO2 finally come to the separator at atmospheric pressure & get precipitated. CO2 leaving the separator is then measured by passing it through a CO gas flow meter. Process description for commercial scale plant The raw material in powder form is fed to the extractor. The liquid carbondioxide from the CO2 tank is precooled by passing it through the precooler. This precooled liquid carbon dioxide is then pressurized by means of a positive displacement plunger pump to a pressure above the critical pressure of CO2 (i.e. 73.8 bar). High pressure liquid CO2 is then heated above the critical temperature of CO2 (i.e 31 °C) by passing it through preheater. CO2 which is now in the supercritical state enters the extractor in which the raw material is loaded. The SCCO2 dissolves substances on the basis of solubility, depending on operating conditions. The SCCO2 with soluble extracts enters the separators where the pressure & temperature are reduced sequentially so that solubility decreases & extract precipitates in the separators. Finally the clean CO2 without any traces is recycled back to the CO2 tank via condenser.

Supercritical CO2 Extraction System

Get Price Quote

A green technology to extract absolutes with the help of supercritical CO2 as a solvent instead of conventional solvent extraction and steam distillation which take up a lot of energy and time for extractions. This SCFE is faster and greener. You get pure extracts free from pesticides, impurities, free from solvent even in ppb levels. Go for the Green Technology of the Future.

liquid extraction

Get Price Quote

The Liquid-Liquid Extraction allows liquid mixtures to be separated using liquid-liquid extraction. The liquid mixture to be separated is delivered from the feed tank into the bottom of the extraction column using a gear pump. There, it moves in countercurrent towards the solvent, which is delivered into the top of the packed column by a diaphragm pump. The mixture to be separated is made up of a transition component and carrier liquid. The carrier liquid and the solvent are insoluble in one another and therefore a phase boundary is established in the column. This can be adjusted using two regulating valves. The movement of the transition component from the carrier liquid into the solvent occurs inside the packed column. Two three-way valves can be used to operate the system as a closed or an open process. To obtain the transition component and allow reuse of the solvent, the extract can be processed using a distillation unit. This consists of a round-bottomed flask with a packed column and a distillation bridge with Liebig condenser. A hemispherical heating mantle is used to heat the bottom product in the round-bottomed flask. The bottom temperature is measured by a sensor, displayed digitally and controlled using a PID controller. The temperature at the top of the distillation column is also measured. Distillation removes the solvent from the transition component which is collected at the bottom of the unit and can be drawn off as a product. The distilled solvent is collected in a tank and can be reused in the extraction process. For a ternary material system, boiling petrol is recommended as the carrier liquid with benzoic acid as the transition component and distilled water as the solvent. A pH and conductivity meter is included to monitor the efficiency of the separating process.

liquid Extraction Unit

Get Price Quote

We offer high quality liquid extraction unit that is designed for liquid-to-liquid extraction as a means of separation. The liquid extracted is treated with the solvents of different density. The unit is supplied with solvent feed either from top of from bottom, or with common arrangement. Moreover, we are identified as one of the most reputed mini liquid extraction unit exporters, based in india.

liquid Extraction Unit

Get Price Quote

Liquid Extraction Unit that we manufacture, export and supply is also known as solvent extraction unit in which separation of constituents of a liquid solution is done by contacting it with another insoluble liquid. Our Liquid-Liquid Extraction Unit is for semi-batch operation. We make available our Liquid Extraction Unit in vessel size of 10, 20 and 50 ltr. It is suitable for operation under atmospheric pressure. Functioning : The extracted liquid is poured into an extraction vessel and the solvent is in a reboiler vessel and condensed in an overhead condenser. The condensed liquid is then collected in a reflux divider and passes through pipework to the extraction vessel. The pipework incorporates valves in order that the solvent can enter the extraction vessel at either the base or the top, depending on the elative densities of the solvent and liquid to be extracted. The solvent and the extracted liquid pass back to the reboiler and process is repeated unit the extraction is complete. The extraction vessel is then drained and the solvent evaporated from the reboiler vessel and collected in the extraction vessel enabling the two liquids to be drained from their respective vessels.

Supercritical Fluid Extraction System

2,500,000 Per Unit

Solid-Liquid Extraction Packed Bed Type

Get Price Quote

Fluid Extraction System

Get Price Quote

One Set(s) (MOQ)

We are offering rumen fluid extraction unit for cattle and camel.