Water Jet Ejector

Get Price Quote

Water Jet Ejectors / Eductor : Water jet ejectors (Liquid Eductors) uses water as motive force. Liquid Jet Eductors use the kinetic energy of a motive liquid to entrain another liquid,completely mix the two, and then discharge the mixture against a counter pressure and are used in large numbers throughout industry for pumping and mixing operations. Water Jet Eductors consist of three basic components, namely a converging nozzle, a diffuser (or venturi), and a body to hold these parts in their relative positions and to provide a suction (or mixing) chamber. In addition, they can be equipped with accessories such as regulating spindles. Water Jet Eductors can also be staged with higher vacuum steam ejectors. In this case, the eductor serves both as the final pumping stage as well as a fairly good direct contact condenser, condensing the motive steam from the high vacuum steam ejectors. When designing eductors experience is all-important to correctly design the nozzle, diffuser, and body and their relative positions as they are all highly critical and vary according to the physical properties of the liquids being handled. Applications are so numerous, it is impossible to note all of them. General uses include lifting, pumping, mixing, and agitating of liquids as well as handling granular solids and slurries. Benefits : Low Cost - Units are small in relation to the work they do and cost is correspondingly low. Self Priming - Eductors are self-priming. They operate equally well in continuous or intermittent service. No Moving Parts - Eductors are exceedingly simple and reliabl-e. There are no moving parts to wear or break in a basic eductor. Even when equipped with accessories such as regulating spindles snap valves, float mechanisms, they require little attention, only periodic inspection and maintenance Corrosion and Erosion Resistant - Because they can be made of practically any workable material, or coated with corrosion-resistant materials eductors can be made highly resistant to the actions of the liquids handled or The environment in which located. Safe - Eductors can be used in hazardous locations where electrically operated alternates would require explosion proofing at considerable cost. Versatile - Various piping arrangements permit adapting to environmental conditions. Eductors of vanoustypes can handle granular solids, semi-solids, and slurries without contamination. Automatically Controlled - Units can be adapted for automatic control by means of a pressure liquid regulating spindle or a snap-valve and float arrangement. Easy to Install - Connections can be made to suit your piping requirements. Little space is required to accommodate units and they are normally so light in weight they can be supported by the piping to which they are attached.

Liquid Collector Ejector

Get Price Quote

1 Piece (MOQ)

Collects the leakage of expensive cutting and grinding oil Eliminates the need to collect the leaked liquids by hand It is possible to use the equipped pump. A special driving force is not required.

Best Deals from Liquid Jet Ejectors

Cast Iron Ejector

Get Price Quote

Liquid Jet Ejectors

Get Price Quote

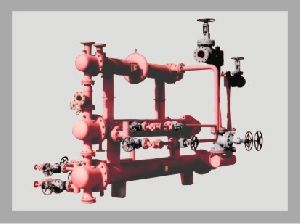

we are offering liquid jet ejectors. liquid jet ejectors are specially designed to operate using water, solvent or any other clear liquid and generate vacuum corresponding to the vapor pressure of the liquid. they are very useful for applications when expensive process fluid is to be recovered. they are most suitable for low non-condensable and high condensable loads in applications like distillation and evaporation. external heat exchanger can be provided to maintain liquid temperature in accordance with vacuum requirement. for higher vacuum, liquid jet ejector can be utilized along with a steam jet ejector combination system. the whole system can be supplied as a pre-assembled skid mounted unit for quick installation. we at crystal tcs have gained considerable expertise at developing the involved technology and designing these devices to suit the needs of the application. add to that our experience in the field and we assure that your application will be completely satisfied.

Steam Jet Ejectors, Liquid Jet Ejectors

Get Price Quote

We are offering steam jet ejectors, liquid jet ejectors. Ejectors may, in one sense, be put into two categories: condensing and noncondensing :- three-stage condensing air ejector and a three-stage noncondensing air ejector. the condensing type utilizes condensers between ejector stages to remove condensable vapor and, therefore, require a source of cooling water. The noncondensing ejector directly together, with succeeding stages handling the motive has its stages connected steam from preceding stages. This type requires no cooling water. However, it uses considerably more steam than the condensing type to handle a given load. ejectors for pilot plants differ from production plant units in as much as noncondensing~type units are normally recommended wherever possible. usually, higher first cost means lower steam consumption and better economy in the long run.

Caustic Ejectors

10,000 Per Set

Our Ejectors deliver chemicals more safely and with greater precision and reliability than traditional delivery methods. There is no moving parts, ejector system is also a safe system because the injected material is not under pressure. If the water flow stops, injection stops instantly. Our ejectors are able to run dry with no problems and because they are made with special lined material & they last longer.The system uses differential pressure between inlet and outlet ports to create a vacuum, which draws chemicals through the suction port. Internal mixing vanes help ensure even distribution and installations do not require a pump or motor.These systems are fabricated using superior quality raw material and possess following parts and features Excellent safety because injected material is not under pressure; if water flow stops, injection also stops instantly Uniform distribution of material means accurate delivery Able to run dry with no problems Ebonite lined / PP Lined corrosive resistance material means long wear life

Liquid Jet Ejector

10,000 Per Units

5 Units (MOQ)

Water Jet Ejector

Get Price Quote

We are offering water jet ejector. water jet ejector is a simple device which works on bernoull’s principle, a jet of moto fluid leaves a converging divering nozzle at a very high velocity which in turn generates very low pressure at the nozzle due to which a vacuum is created & the air or other gases are being sucked in through the in let flange. A single stage water jet ejector can produce vacuum as low as 720 mm/shg.l.e.40 mm hg. Abs. Pressure. With such a simple & handy working procedure, this device is not only economical but also is a substitute for the conventional vacuum pumps.

Liquid Jet Ejectors

Get Price Quote

Steam Jet-Liquid Jet Ejector systems to handle small quantities of non-condensable and non condensable vapors and to scrub Gas also of outlet gases, its also available in various MOC for Batch and Continuous Application also. Ejector system are used in several industries Like OilPetro Chemicals, Vacuum Drying, Dehydration, Evacuation Vacuum Filling, Conveying, Venting.

WATER EJECTOR

2,999 Per Piece

Item Description : Water Ejector having 100mm MRT & 63mm Male Inst. inlet with 100mm MRT outlet made of Alu. Alloy with Handle. Connections : 63 mm Instantenous Male Inlet, 4” RT Male Suction, 4” RT Male Discharge capacity : approx. 400 GPM at 5 kg/cm2 inlet pressure.

Liquid Jet Ejectors

Get Price Quote

In a liquid Jet Ejector, the motive fluid is a non-compressible liquid (generally water) with no heat energy hence with a single stage centrifugal pump we can not increase its pressure much. As a result motive fluid velocity at the nozzle tip is very less and it affects its non-condensable load handling capacity drastically.

Liquid Jet Ejectors

Get Price Quote

Liquid jet ejector system provides a low maintenance,low cost alternative to other vacuum systems.They are simple in construction consisting of suction housing,diffuser and motive nozzle. The operation of liquid jet pumps is based on high velocity liquid jet emerging from the motive nozzle entraining air or gas in the suction housing and compres- sing it to atmospheric pressure. Liquid jet pumps with flange connections are mainly used for production of vacuum in vacuum distillation,in technical institutes,in production plants and vacuum drying They are used for evacuating siphon lines,suction lines of circulating pumps and and condensers. It requires a complete package unit consisting of a liquid jet ejector,a tank, a circulating pump and a cooling tower unit(cooling tower with circulating pump)cooler. The lowest suction pressure which can be obtained with a suction capacity of zero(blank vacuum)corresponds to vapour pressure of the motive liquid,which is dependent upon the temperature of the liquid.

WATER EJECTOR

Get Price Quote

MOC : Copper Alloy (Gunmetal) / Alu. Alloy (Light Alloy)/Stainless SteelInlet : 63 mm size Male Instantaneous Inlet to Operate with Pressurized Water 100 mm Size Round Threaded (BSRT) Suction InletOutlet : 100 mm Size Round Threaded (BSRT)Finish : Painted Fire Red/ PO Red with Male Instantaneous Inlet Polished

Liquid Jet Ejectors

Get Price Quote

liquid jet ejectors are specially designed to operate using water, solvent or any other clear liquid and generate vacuum corresponding to the vapor pressure of the liquid. They are very useful for applications when expensive process fluid is to be recovered. they are most suitable for low non-condensable and high condensable loads in applications like distillation and evaporation. External heat exchanger can be provided to maintain liquid temperature in accordance with vacuum requirement. For higher vacuum, liquid jet ejector can be utilized along with a steam jet ejector combination system. the whole system can be supplied as a pre-assembled skid mounted unit for quick installation. they are available in stainless steel, carbon steel, duplex steel, hastelloy, titanium, rubber lined, pp, ptfe and pvdf. how it works liquid jet ejectors are jet pumps, motivated by a high pressure liquid. They use the kinetic energy of the pressure liquid to entrain gases and vapors, slurries and other liquids or granular solids and then discharge the resultant mixture against a counter pressure. key advantages maintenance free easy to operate facilitate for low level installation simple in design reliable in operation no moving parts, hence minimal maintenance inline mixing of liquid and gas virtually silent operation suitable for hazardous areas custom designed

Condenser Four Stage water Ejector

Get Price Quote

Four Stage Ejector is having construction and working similar to Single Stage, Two Stage & Three Stage Ejector. When ejector is to be installed at low ambient temperature area, primary booster should be steam jacketed to prevent building up of ice on the diffuser internal bore. Sometimes both primary and secondary boosters are completely jacked to avoid deposition of product inside the ejector. The Four Stage Ejector consists of following components: » Primary Booster Ejector » Secondary Booster Ejector » Booster Condenser » Vacuum Ejector » Inter Condenser » Low vacuum Ejector

Stainless Steel Water Jet Ejector

100,000 Per Units

WATER EJECTOR

Get Price Quote

Usage : For removal of slumy and mud, etc. Material of Construction : Aluminium alloy body, Aluminium G.M nozzle Size : 4"(100 mm). Item Description : Water Ejector having 100mm MRT & 63mm Male Inst. inlet with 100mm MRT outlet made of Alu. Alloy with Handle. Connections : 63 mm Instantenous Male Inlet, 4” RT Male Suction, 4” RT Male Discharge capacity : approx. 400 GPM at 5 kgcm2 inlet pressure. Finish : Buff Polished Painted Guarantee : For the period of 12 months from the date of supply.

Liquid Jet Ejectors

Get Price Quote

Liquid Jet Ejectors are simple in construction consisting of suction, Diffuser and Motive Nozzle. The operation of Liquid Jet Ejectors is based on high velocity liquid emerging from the motive entraining air or gas in the suction housing and compressing it to atmospheric pressure. Easy to install. Minimum maintance. Easy Operation. Because of simple construction they are widely used for following Purpose.

Water Steam Jet Vacuum Ejector

Get Price Quote

Water jet ejectors

Get Price Quote

We are manufacturing water jet ejectors In different MOC Like MS, SS 304 & 316, PP and Graphite. These are available at competitive prices