Lost Wax Process

Get Price Quote

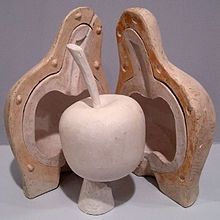

WAX INJECTION - Investment Castings process starts with production of wax patterns by injecting wax in to dies. A pattern is required for each castings. Wax patterns have exact dimensions of the required finished castings, subject to shrinkage etc. PATTERN ASSEMBLE - Wax patterns are then assembled to one or more runners and then runners are attached to pouring cups. This assembly when completed is called tree or cluster. SHELLING - This process involves dipping the tree or cluster in to different types of ceramic slurry, draining it then again coating. This process is repeated until desired shell thickness is achieved. DEWAXING - The coated cluster is placed in a high temperature furnace where the pattern melts and runs out through the gates, runners and pouring cu. This leaves a ceramic shell containing cavities of the casting shape desired with passages leading to them. CASTINGS - Before pouring molten metal, shells are fired to burn out residual wax, and to give desired strength in shells, so as to bear pressure & heat at the time of pouring. Moulds may be poured with help of vaccum, pressure or centrifugal force. CLEANING & FETTLING - Ceramic slurry is then removed by knocking or by abrasive blastings.Each casted component is then removed by either plasma cutting torch or by cutt off wheels. FINISHING & DISPATCHING - Each component is then cleaned through gates etc by grinding and then polishing by Shot/Sand blastings.Castings is then ready for final inspection and dimensional check etc.After this process is completed castings are then ready for dispatching.

Lost Wax Castings

260 Per Kilogram

As we know the value of quality raw materials, we source them only from dependable vendors. By applying such inputs, we make sure that our finished goods remain flawless. To avoid any type of mechanical and biochemical harms, we pack our products in high-grade packing items that are sturdy as well. Moreover, we provide product details on it as well. Specifications : Material : Stainless Steel Available Material : Aluminum, Zinc, Copper, Brass Type : Casting Brand : Godani

Best Deals from Lost Wax Casting

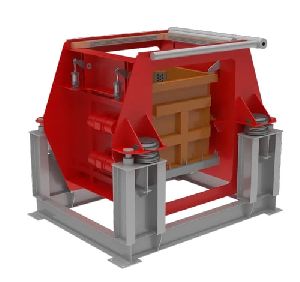

Automatic Lost Foam Compaction Table

849,000 Per Piece

1 Piece (MOQ)

lost foam casting

Get Price Quote

Lost Foam Casting / Lost Wax Casting Die dies are used to create the foam patterns used in the LFC process. These dies are typically made of aluminium or steel and are precision-machined to create the desired pattern. The foam pattern is coated with a refractory material, which is then heated to create a hard shell. Molten metal is then poured into the shell, filling the void left by the foam pattern and forming the desired part.

Lost Wax Casting

Get Price Quote

We are main supplier of this product.

Lost Wax Casting

Get Price Quote

Lost Wax Casting for Automobile components

550 Per kg

100 KG (MOQ)

Lost Wax Investment Castings

240 - 580 Per Kilogram

Lost Wax Castings

250 Per Kilogram

Lost Wax Castings

Get Price Quote

Offering Lost Wax Castings, Energy Technocast is a leading manufacturer & supplier of quality investment castings products for a wide range of industries including Industrial valves, Fittings, Industrial process pumps, Fire fighting industry, Automobile industry, Defense & Aerospace industry, Marine industry, Medical implants & Custom general engineering.

Lost Wax Castings

Get Price Quote

Lost Wax Casting

Get Price Quote

This technique used by many jewelers because they can produce manual and interesting designs. Main advantage of the lost wax casting is you can use own models plus designs for caster cast and polishing of pieces. Energy Technocast always follows high quality procedure of lost wax casting to produce efficient investment casting parts and designs. We are strictly following international standard and specification to produce precise shapes and high dimensional parts.

Lost Wax Casting

Get Price Quote

Investment casting or lost wax casting is well known ancient metal casting process gives freedom to design most difficult shapes with perfect dimensional accuracy. The process is suitable for casting precision metal through wax utilization and metal dies. It is slightly expensive than sand or die castings but assures high quality product with better surface finish and high tensile strength at the end. Being reliable Investment Casting Manufacturer and exporters in India, we have earned prominent name worldwide. We at Castech India use high quality raw materials procured from top vendors in the industry. We are the trusted Casting Manufacturers and suppliers in India focus more on delivering product with high strength and well finishing.

Lost Wax Casting

Get Price Quote

From using 2D drawing of investment casting provided by customer, we manufacture die (patterntools) of Aluminum material using CADCAM. We send drawing to customer for approval making appropriate changes in drawing based on lost wax casting process requirement. We technically support our customers for developing cost effective product based on materialmachining cost savings.

Lost Wax Casting

Get Price Quote

We have diversified into manufactore of investment castings by lost wax process in 2003. Parikh udyog is aiming to manufacture critical, precision & value added castings of various high quality grades.

Lost Wax Casting

Get Price Quote

Lost Wax Casting

Get Price Quote

Lost wax process castings are ancient and popular approach in India that assures most intricate and précised components to clients at very competitive prices.Lost wax process castings are green manufacturing solution and convenient too.

Lost Wax Casting

Get Price Quote

Lost Wax Casting

Get Price Quote

Lost Wax Casting

Get Price Quote

Lost wax casting are known for Manufacturing, Exporting high quality Investment Casting Components. We adhere to all set industry standards and use only high grade metals to forge finest Investment Casting Components. We have gained the trust of our clients for supplying durable, corrosion resistant and excellent finish Investment Casting Components at affordable prices. Timely delivery of all orders is our priority.