Magnetic Particle Testing Training Service

Get Price Quote

Our Magnetic Particle Inspection Training Service offers comprehensive instruction to professionals seeking proficiency in this vital non-destructive testing technique. Through a blend of theoretical concepts and hands-on practical exercises, participants learn to detect surface and near-surface flaws in ferromagnetic materials with accuracy and precision. Led by experienced instructors and utilizing state-of-the-art equipment, our training equips individuals with the skills and knowledge required to conduct thorough inspections across various industries, including automotive, aerospace, and manufacturing. Trust us to empower your team with the expertise to ensure the integrity and safety of critical components.

magnetic particle testing service

Get Price Quote

Our magnetic particle testing service offers precise inspection of ferromagnetic materials to detect surface and near-surface defects. Utilizing advanced magnetic particle inspection techniques, we apply magnetic fields and particulate substances to reveal cracks, voids, and other irregularities. Our certified technicians ensure thorough testing and accurate results, helping you maintain structural integrity and safety. We are committed to delivering reliable, high-quality service to support your quality control and maintenance needs with efficiency and expertise.

Looking for Magnetic Particle Testing Service Providers

magnetic particle testing service

Get Price Quote

Trinity NDT is your trusted partner for Magnetic Particle Testing (MPT) services. With a commitment to excellence and safety, we offer a comprehensive range of MPT solutions to ensure the integrity and reliability of critical components and materials in various industries. Our Magnetic Particle Testing Services Include: Magnetic Particle Inspection: We utilize state-of-the-art equipment and methodologies to detect surface and subsurface flaws and defects in ferromagnetic materials. Our highly skilled technicians ensure accurate and reliable results. Portable MPT Solutions: We offer on-site and field services, providing convenience and flexibility for inspections in various environments, including manufacturing facilities, construction sites, and more. Customized Testing: Trinity NDT tailors its MPT services to meet your specific requirements. We understand that each project is unique, and we are dedicated to providing personalized solutions. Industry Expertise: Our experience spans a wide range of industries, including aerospace, automotive, oil and gas, and manufacturing, making us well-equipped to handle diverse testing needs. At Trinity NDT, we adhere to strict quality and safety standards, ensuring the highest level of accuracy and reliability in our Magnetic Particle Testing services. We take pride in contributing to the safety and performance of your projects. Contact us today to learn more about how Trinity NDT's Magnetic Particle Testing services can meet your inspection needs.

magnetic particle testing

2,000 Per test

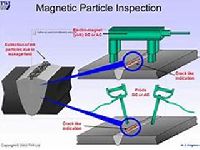

Magnetic Particle Inspection (MPI) MAGNETIC PARTICLE INSPECTION Magnetic Particle Inspection (MPI) is an NDT method that can use magnetism to detect surface and subsurface discontinuities in ferromagnetic materials. MPI is generally used to determine parts fitness for use. It is a relatively easy and quick method that is widely used in various sectors such as automotive, oil and gas, aerospace, petroleum, power generation, etc. This method detects surface or subsurface discontinuities such as cracks, porosity, laps, seams, inclusions in ferromagnetic materials. One of the major advantages of this method is, it is a relatively fast method and gives an immediate indication on the surface. This method works by inducing the magnetic flux in the part to be tested. If any discontinuities or detect is present on the surface or near the surface the magnetic field distorts and leaks around the defect. By application of magnetic medium on the surface, the particles attract the area where flux leakage has occurred producing a visible indication of the defect. This indication can be evaluated by the operator any necessary measures are taken if any. Our techniques for magnetic particle inspection include: · Yoke · Bench (for headshot direct induction) · Coil shot · Prods · Central conductor ALPHA SONIX has skilled NDT personnel that have gained years of experience in performing MPI and are Level 2 and 3 qualified with ASNT. We provide the testing both on-site at our customers’ premises. When selecting ALPHA SONIX for your magnetic particle inspection (MPI) needs, you have an assurance that your maintenance schedules will be met and you will benefit from the expertise that our inspectors provide. Our reports will provide you with the necessary data to take preventive measures and will help in the management of assets.

Magnetic Particle Testing Services

Get Price Quote

In case there are any particles of ferromagnetic material present in any surface, it might attract the magnets or iron and cause problem in different processes. At Dwija Engineering LLP, we are known to be offering highest grade magnetic particle testing services in Ahmedabad (Gujarat, India). We can test the presence of all types of ferromagnetic material like iron, cobalt, nickel, or their similar alloys with magnetic properties. Your production lines are tested by us and we produce magnetic line of force to ensure that there are any magnetic properties or not in them. So, contact us to get best in class services. Dwija engineering LLP is a renowned company that is engaged in manufacturing, exporting and supplying a large number of products in the regional and global marketplace. We are counted amongst the best company that provides magnetic particle testing in Ahmedabad. We ensure that no particles of ferromagnetic material that might attract the magnets or iron, is present in any surface. We are known to offer the highest grade magnetic particle testing services (MPT) in Ahmedabad. We have a professional team that can detect the presence of all types of ferromagnetic material like iron, cobalt, nickel, or their similar alloys having magnetic properties. Our professional team experts tests our clients’ production lines. Also, we produce magnetic line of force to ensure the presence of any magnetic properties in them. We work with our clients to meet their required demands within the given time span and avoid any type of hassle while rendering our services. We are completely committed to customer satisfaction. We have several years of experience in the field of engineering. So, contact us if you don’t want magnets or iron to cause problems in your production line, get the best magnetic particle testing services at the most reasonable charge.

magnetic particle testing

Get Price Quote

Magnetic Particle Inspection (MPI) is a Non-Destructive Testing (NDT) process for detecting surface and slightly subsurface discontinuities in ferroelectric materials such as iron, nickel, cobalt, and some of their alloys. The process puts a magnetic field into the part. The piece can be magnetized by direct or indirect magnetization. Direct magnetization occurs when the electric current is passed through the test object and a magnetic field is formed in the material. Indirect magnetization occurs when no electric current is passed through the test object, but a magnetic field is applied from an outside source. The magnetic lines of force are perpendicular to the direction of the electric current which may be either Alternating Current (AC) or some form of Direct Current (DC) (rectified AC). The presence of a surface or subsurface discontinuity in the material allows the magnetic flux to leak, since air cannot support as much magnetic field per unit volume as metals. Ferrous iron particles are then applied to the part. The particles may be dry or in a wet suspension. If an area of flux leakage is present the particles will be attracted to this area. The particles will build up at the area of leakage and form what is known as an indication. The indication can then be evaluated to determine what it is, what may have caused it, and what action should be taken, if any. This examination should apply in a row stage and final stage. Process mostly used for bar stage,forging casting and after heat treatment process .

magnetic particle testing service

2,000 - 4,000 Per Price

magnetic particle testing

Get Price Quote

MAGNETIC PARTICLE INSPECTION For Detection of Surface and Subsurface cracks Magnetic particle inspection is often carried out to help determine an item’s fitness for use or conformity. This quick and relatively easy to apply technique is widely used in all industry sectors including aerospace, automotive, petrochemical, structural steel, and power generation to inspect a variety of products and equipment such as engine, suspension and braking system components, castings, forgings and weldments etc.

Magnetic Particle Testing Services

3,000 - 6,000 Per D

MT detects surface and near-surface imperfections such as cracks, seams and laps in ferromagnetic materials, and is used to assess location, size, shape and extent of these imperfec- tions. When the test object is magnetized, flaws perpendicular to the magnetic field direction cause f lux leakage. Magnetic particles applied to the surface are held at the location of the imperfection by flux leakage.

Magnetic Particle Testing Services

Get Price Quote

This process used for detecting surface and slightly subsurface discontinuities in ferroelectric materials such as iron, nickel, cobalt, and some of their alloys. The process puts a magnetic field into the part. The reason we use this test is to find small defects in objects before they become bigger defects and cause serious problems. In magnetic particle inspection, a magnet or electrical current is used to establish a magnetic field in the object. Iron filings are then dusted on to the surface of the object. The filings should align along the magnetic lines of force. If a crack or other defect is present, the magnetic lines of force will be disrupted and the magnetic particles will cluster along the edges of the flaw.

magnetic particle testing

Get Price Quote

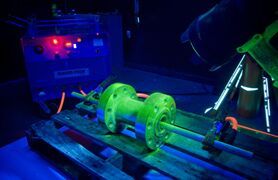

A technician performs MPI on a pipeline to check for stress corrosion cracking using what is known as the "black and white" method. No indications of cracking appear in this picture; the only marks are the "footprints" of the magnetic yoke and drip marks.A close-up of the surface of a (different) pipeline showing indications of stress corrosion cracking (two clusters of small black lines) revealed by MPI. Cracks that would normally have been invisible are detectable due to the magnetic particles clustering at the crack openings. The scale at the bottom is numbered in centimetres.Magnetic particle Inspection (MPI) is a non-destructive testing (NDT) process for detecting surface and shallow subsurface discontinuities in ferromagnetic materials such as iron, nickel, cobalt, and some of their alloys.

magnetic particle testing

500 Per Meter

Mt (magnetic particle testing) it is a non-destructive testing (ndt) process for detecting surface and slightly subsurface discontinuities in ferromagnetic materials such as iron, nickel, cobalt, and some of their alloys. The process puts a magnetic field into the part. The piece can be magnetized by direct or indirect magnetization. Direct magnetization direct magnetization occurs when the electric current is passed through the test object and a magnetic field is formed in the material. Indirect magnetization indirect magnetization occurs when no electric current is passed through the test object, but a magnetic field is applied from an outside source. Dry particle inspection in this magnetic particle testing technique, dry particles are dusted onto the surface of the test object as the item is magnetized. Dry particle inspection is well suited for the inspections conducted on rough surfaces. When an electromagnetic yoke is used, the ac or half wave dc current creates a pulsating magnetic field that provides mobility to the powder. The primary applications for dry powders are unground welds and rough as-cast surfaces. Dry particle inspection is also used to detect shallow subsurface cracks. Dry particles with half wave dc is the best approach when inspecting for lack of root penetration in welds of thin materials. Half wave dc with prods and dry particles is commonly used when inspecting large castings for hot tears and cracks. Wet suspension inspection wet suspension magnetic particle inspection, more commonly known as wet magnetic particle inspection, involves applying the particles while they are suspended in a liquid carrier. Wet magnetic particle inspection is most commonly performed using a stationary, wet, horizontal inspection unit but suspensions are also available in spray cans for use with an electromagnetic yoke.

Magnetic Particle Testing Services

Get Price Quote

Magnetic particle testing is a method for detecting cracks and other discontinuities on surface and subsurface of Ferro-magnetic materials. Sensitivity of detection is maximum at the surface and diminishes rapidly with increasing depth of sub-surface defects. Detection of defects depend on the fact that when a material is magnetized, discontinuities which lie transverse to the direction of magnetization cause distortion of the magnetic lines of flux and a leakage field is formed at or above the surface, some of these particles are held by the leakage flux. These magnetically held collection of particles form outline of effects and show location, shape and extent of the discontinuities. A number of factors such as direction and strength of the magnetic field, magnetic character of the part, location and orientation of discontinuities and type of the magnetic powder applied, affect the formation of the powder pattern, and therefore exact location of the flaw is indicated by the method.

magnetic particle testing

Get Price Quote

This method is used for the detection of surface and near-surface flaws in ferromagnetic materials and is primarily used for crack detection. The specimen is magnetised either locally or overall, and if the material is sound the magnetic flux is predominantly inside the material. If, however, there is a surface-breaking flaw, the magnetic field is distorted, causing local magnetic flux leakage around the flaw. This leakage flux is displayed by covering the surface with very fine iron particles applied either dry or suspended in a liquid. The particles accumulate at the regions of flux leakage, producing a build-up which can be seen visually even when the crack opening is very narrow. Thus, a crack is indicated as a line of iron powder particles on the surface. The method is applicable to all metals which can be strongly magnetised – ferritic steels and irons, but not generally austenitic steels. The method of magnetisation must produce a magnetic field with lines of force at a large angle to the expected direction of the cracks to be detected, so that it is usual to apply the magnetisation more than once in different directions, for example in two directions mutually at right-angles, but methods of swinging the field direction during magnetisation are available.

magnetic particle testing

Get Price Quote

Magnetic particle Inspection (MPI) is a non-destructive testing (NDT) process for detecting surface and slightly subsurface discontinuities in ferromagnetic materials such as iron, nickel, cobalt, and some of their alloys. The process puts a magnetic field into the part. The piece can be magnetized by direct or indirect magnetization. Direct magnetization occurs when the electric current is passed through the test object and a magnetic field is formed in the material. Indirect magnetization occurs when no electric current is passed through the test object, but a magnetic field is applied from an outside source. The magnetic lines of force are perpendicular to the direction of the electric current, which may be either alternating current (AC) or some form of direct current (DC) (rectified AC).

magnetic particle testing service

Get Price Quote

It's necessary to conduct flawless magnetic particle testing services to identify defects on the surface of ferromagnetic materials. The whole task gets done by running a magnetic current through it. We at Suman NDT Repair Service concentrate on offering top-notch magnetic particle testing services as per the guidelines. We combine the latest scientific techniques and innovative ideas to deliver wonderful magnetic particle testing services. Our expert members are knowledgeable about all the aspects of effective magnetic particle testing. Being a noteworthy brand, we always take care of the different needs of our clients. Our charges are also much lesser than the other brands. Thus contact Suman NDT Repair Service to receive outstanding magnetic particle testing services.

NDT Training - Magnetic Particle Testing

2,500 Per Pack

Magnetic particle Inspection (MPI) is a non-destructive testing (NDT) process for detecting surface and slightly subsurface discontinuities in ferromagnetic materials such as iron, nickel, cobalt, and some of their alloys. The process puts a magnetic field into the part. The piece can be magnetized by direct or indirect magnetization. Direct magnetization occurs when the electric current is passed through the test object and a magnetic field is formed in the material. Indirect magnetization occurs when no electric current is passed through the test object, but a magnetic field is applied from an outside source. The magnetic lines of force are perpendicular to the direction of the electric current, which may be either alternating current (AC) or some form of direct current (DC) (rectified AC). A technician performs MPI on a pipeline to check for stress corrosion cracking using what is known as the "black and white" method. No indications of cracking appear in this picture; the only marks are the "footprints" of the magnetic yoke and drip marks. A close-up of the surface of a (different) pipeline showing indications of stress corrosion cracking (two clusters of small black lines) revealed by magnetic particle inspection. Cracks that would normally have been invisible are detectable due to the magnetic particles clustering at the crack openings. The scale at the bottom is numbered in centimetres.

magnetic particle testing

6,000 - 8,000 Per DAY

magnetic particle testing, Third party Inspection

magnetic particle testing

Get Price Quote

We are providing magnetic particle testing services. We are magnetizing the inspection job and applying magnetic particle (dry or wet magnetic particle)on surface of the part. Then we will get the indication on the job surface (indication -> particle accumulation) due to the magnetic flux leakage. Using this visible indication we can identify the type of defects in the material. This ndt method is called as “magnetic particle testing”

Magnetic Particle Testing Services

Get Price Quote

Magnetic particle testing or MPT is a nondestructive testing method for locating surface and near surface discontinuities in ferromagnetic materials.