Electro Permanent Magnetic Chuck

60,000 Per Piece

1 Piece (MOQ)

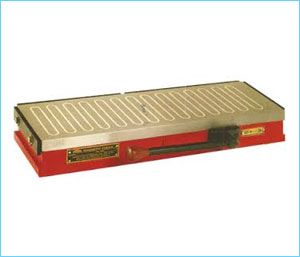

Electro Magnetic Chuck

25,000 Per Piece

1 Piece (MOQ)

Best Deals from Magnetic Chucks

Permanent Magnetic Chuck

8,500 Per Piece

10 Piece (MOQ)

Long Pole Series

Get Price Quote

We are engaged in the manufacturing and supplying of Rectangular Electro Magnetic Chucks. The Rectangular Electro Magnetic Chucks are manufactured using quality raw materials procured from the reliable sources. These Rectangular Electro Magnetic Chucks have powerful magnetic pulling force and these can be used on grinding, milling, planning, and shaper machines. The top plate of Rectangular Electro Magnetic Chucks is made using steel and aluminum sated together. These Rectangular Electro Magnetic Chucks have high mechanical rigidity and proven robustness. These electro magnets are easy to install on machines as they have long bottom plates. These can be clamped from bottom plates on machine table. Electro Magnetic Chucks are manufactured in cross pole and long pole series. Again both series can be classified in two types of poles i.e. Standard poles and Close poles. These Rectangular Electro Magnetic Chucks are tested for water proofing. Poles of chucks are extended for maximum effective magnetic clamping area. These Rectangular Electro Magnetic Chucks have multiple coils for powerful magnetic pull. These Rectangular Electro Magnetic Chucks are manufactured in standard sizes but special size chucks can be made on order. Use : The standard pole electro magnets can be used on grinding, milling, planning, drilling and shaper machines for holding big or medium components where as close pole electro magnets can be used for holding smaller components comparatively.

Belt Grinder Magnetic Chuck

1,500 Per Piece

1 Piece (MOQ)

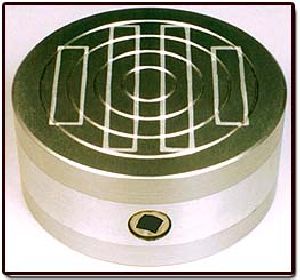

Magnet Chucks - Round

Get Price Quote

Round Magnet are also supplied by us in the market to fulfill the requiremetn of the customer. They come in Standard Pole / Close Pole We have very good range of Quality Magnets in vey competitive prices.

Magnetic Chucks

1,200 - 1,800 Per Set

50 Piece (MOQ)

Magnetic therapy has been known to heal certain health conditions and body aches for years. It gained popularity in Australia, France, India, China, Germany, Japan, and Egypt, and became legitimate in the medicinal field. Because of that, magnetic products such as bracelets, slippers and pads have emerged in the market. Magnetic Mattress pads involve the use of magnets. Most magnetic mattress pads are made of foam and in different sizes. Continuous strip magnets are inserted inside the foam and cover the whole bed to surround the entire body. The magnets aim to restore energetic imbalances that the body undergoes when it is in pain. The benefits of magnetic mattress pads include pain relief especially from backaches and migraines, fast wound and bone healing, improved overall blood circulation, and improved sleeping patterns. In rare cases, the side effects of using a magnetic mattress pad are nausea and dizziness, a decrease in blood pressure, and pain over some local skin areas.

Magnetic Chuck

6,000 Per Piece

Magnetic Chuck, electric discharge machine, 5030 ZNC EDM Machine

Electromagnetic Chuck

Get Price Quote

1 Piece (MOQ)

Through Pole Permanent Magnetic Chuck

20,500 Per Piece

As per requirement Piece (MOQ)

Details : Holding device for surface grinding machine, Tool & cutter grinder, Spark erosion Machines & also for light milling. Poles individually magnetized for full loading power. Magnetic pull is 40-50% more than IS specification. Better magnetic grip due to close poles.

ELECTRO-PERM MAGNETIC CHUCK

Get Price Quote

Electro-perm magnetic chuck offers minimum mechanical deformation with solid one piece housing. This chuck is a COLD device. These chucks do not consume electrical power only when activation and deactivation of magnets power is required. This results in very less consumption of electricity as compared to conventional electrical chucks. EPM chucks are economical for operation and maintenance and also most powerful chucks. These chucks are switched ONand OFF with simple electrical pulse. A variable output from 20% to 100% is controlled from one push button switch.EPM chucks are entirely independent of external power supply during the holding of work pieces. So no risk when power fails. The demagnetization cycle of EPM chucks reduces possible residual magnetism in the work piece.

Permanent Round Magnetic Chuck

Get Price Quote

Prod. No. 57 High power chucks Solid top and bottom plates ensure retained accuracy Full loading power over entire plate Hand release with lathe chuck key provided Standard pole and fine pole available

Permanent Magnetic Chuck

Get Price Quote

PML offers highly efficient and durable range of Permanent Magnetic Chucks. The ranges of magnetic chucks are of international quality standard to compete with the best magnetic tools in the market. PML gives importance to each component during manufacturing process and delivers them according to customer's individual specifications. PML offers Rectangular as well as Round Magnetic chucks. They are built using high power Ceramic / Alnico V magnets. These are mainly used for surface grinding machines, tool & cutter grinders, spark erosion machines, etc. PML’s Chucks have strong magnetic grip to hold any ferrous material. The top metal plate is extra thick to ensure maximum accuracy after regrinding. Permanent Magnetic Chucks don’t need power supply and hence do not cause any unexpected accident related to power failures. Since the Chucks don’t need power supply, the cost of operation to the user reduces substantially.

Permanent Magnetic Chuck Fine Pole

25,000 - 90,000 Per Piece

10 Piece (MOQ)

Standard Pole Rectangular Magnetic Chuck

Get Price Quote

Powerful and most suitable for grinding of medium and Large components. Suitable for light milling and drilling perations. Supplied as OE in most surface grinding machines.

Magnetic Chuck

Get Price Quote

1 Piece (MOQ)

electro permanent magnetic chucks

Get Price Quote

Productivity #Accuracy #Reliability: Reinforced Electro permanent systems with extremely High magnetic power. Absolute safety against Power or Cable Fault. Cold operating ensures Ultra Precision machining. An enormous Reduction in clamping and setup times. Customized solutions to suit your requirement. #Simpler #Safer #Super Electro Permanent Magnetic [EPM] Chuck Combines the clamping force of high quality Permanent Magnets with the advantage of switching facilities an Electrical Devices is thereby providing in piratical applications all the prerequisites for precision, safety and ease of operation. A totally original and unique Electro Permanent system is controlled electronically and the clamping zone comprises of a series pf alternate poles. An electric impulse of very high magnitude but of a very short as the chuck is switched ON with the job completing the magnetic circuit the magnets work at BH. Rem & hence is able to provide a magnetic energy perfectly suitable for heavy cuts and thrusts during Grinding, Planning and Milling operations. With these properties we can provide you performance results which has so far been unobtainable from conventional permanent magnetic chucks and hardly obtained in best electromagnetic chucks available. Dimensional Stability The solid construction of the EPM chuck eliminates mechanical distortion and unlike electromagnetic chucks there is in heat generation hence the chuck when once attached to the machine bed will be as geometrically stable as the machine itself providing working surface with uniform holding power required of precision machining. The chuck is entirely static and hence it is not subject to mechanical wear. Total Security The Electronic Control unit is specially designed for Easy and Safe operation of Electro Permanent Magnetic Chucks. Power circuit is controlled by Thrusters and is operated by Remote Control. The switching On/Off of the chuck is done by means of Illuminated push-buttons. The Power consumption is considerably reduced saving almost 98% of precious energy, as only a current pulse for few seconds is required to switch the chuck on and off. Hence the running and maintains cost of the EPM chucks are virtually nonexistent. When in operation the chuck is entirely isolated & independent of power supply. This gives total security against POWER FAILURE and eliminates any risk of accidental release of work piece. Wide Range EPM chucks are available in Grinder series and Milling series in sizes from 200 mm to 1500mm in length and 150 to 400mm in width having longitudinal or transverse poles. Large Magnetic area can be arranged by multiple mounting of chucks which can be operated by a single controller. Special designed to suit yiour particular applications. They are supplied in full working order complete with side plates and power supply cable. FEATURES No electricity required to keep the chuck ON. All Metal Top Plate of Brass and Steel lamination provides full active area. Variable power makes it possible to adjust the magnetic force. It drastically reduces the loading, unloading the work pieces. Hold all type and sizes of work pieces. No heat built up, no deformation provides high precession accuracy. APPLICATION For grinding application of all sizes of jobs. These chucks are suitable for horizontal spindle surface grinding machines as the main cutting thrust is towards the length of the chuck, poles at right angle of the wheel give more gripping of the job. GENERAL APPLICATION These chucks are also available in long pole design. Large area can be arranged by multiple mounting of chucks side by side which can be operated by a single controller. Special purpose chucks can also be designed to suit particular applications. Pole pitch of 2mm (1.5+0.5) can be made at extra cost.

Round Magnetic Chuck

Get Price Quote

Holding device for Rotary surface grinding and also for Lathe & cylindrical grinding machines. Accuracy as per IS : 4816- 1987 Magnetic pullis 20-40% more than IS specification. Assembled with Powerful Magnets. On-Off by key

permanent magnetic chucks

Get Price Quote

Square pole size 50 x 50 Magnetic force higher than 350 kgs per pole Electro-permanent technology with no deformation owing to rise of temperature Minimum mechanical deformation with solid one-piece housing Distortion free clamping with mobile pole extension without stray magnetic fields and no magnetization of the tool workpiece larger than the table size are machinable

Magnetic Chucks

Get Price Quote

The company has created a strong foothold in the business of providing world class Magnetic Chucks. Our Magnetic Chucks are available for grinding, drilling, milling and spark erosion machines. These Magnetic Chucks are vey power full and can be used on milling machines as well. Our quality experts stringently inspect these Magnetic Chucks on various parameters, in order to meet the set industrial standards. Furthermore, the clients can avail these quality-tested Magnetic Chucks in a wide range of sizes to suit all requirements. Attributes Excellent qualityDimensional accuracyDurable life