Rose Gold Master Alloys for handwork

30,000 Per kg

100 gm (MOQ)

handwork rose gold jewellery alloy..Established in the year 2009, we “Jewelcare India” are a prominent firm that is engaged in Manufacturer, Supplier,Exporter a wide range of Gold Alloy, Casting Raw Material, etc

Copper Manganese Master Alloy

840 Per Kilogram

100 Kilogram (MOQ)

Best Deals from Master Alloy

Red Gold Parad Alloy

Get Price Quote

100 Kilogram (MOQ)

Master Alloys

Get Price Quote

1 Ton (MOQ)

Beryllium Copper Master Alloy

3,000 - 10,000 Per Kilogram

Yellow Gold Alloy

Get Price Quote

Yellow Gold Alloy

Get Price Quote

master alloy

Get Price Quote

20000 Kilogram (MOQ)

copper master alloys

Get Price Quote

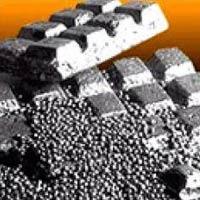

A master alloy is a base metal such as aluminium, copper or nickel combined with a relatively high percentage of one or two other elements. An example is AlTi10 – a binary alloy consisting of 10% titanium in aluminium. A master alloy is a semi-finished product. It is manufactured for use as a raw material by the metals industry. Master alloys are produced in various shapes.A wide variety of high-quality master alloys are used as alloying elements to improve selective mechanical properties of our customer’s final alloy products. The unique combination of physical and mechanical properties of many of our master alloys provide a dynamic range of metallurgical alternatives to meet specific performance requirements.

Palladium,Silver,Platinum,Ruthenium Master Alloys

25,000 Per per Kg

The alloys have the following advantages : Master alloys are prepared under strictly controlled conditions using high purity metals leading to uniform composition and world class quality. They blend easily with gold giving gold alloys with optimum hardness and annealing properties leading to the production of defect free jewellery. These alloys do not oxidise during casting, thereby resulting in clean castings. Specific alloys suitable for casting are available in addition to general purpose alloys. The alloys are ready for immediate delivery. They are backed by extensive technical support. Special alloys can be developed for your specific needs.

copper master alloys

Get Price Quote

We make alloys confirming to international standard suitable to customers requirements for application into manufacturing of Engineering Components, Plumbing & Sanitary Ware, Hardware Products, and Decorative Articles. Different Sizes of the ingots can be provided to fit the customers furnace batch size.

Yellow Gold Coin Alloy

3,000 - 20,000 Per Kilogram

Master Alloys

225 Per Kilogram

1 Kilogram (MOQ)

We are offering sp 154 master alloys for white gold. Composition (wt. %) : ag 20, ni 17, cu 48, zn + deoxidizers – bal. Carat : 10 - 14 colour : white melting temp of alloy : 940c application: the alloy sp 154 is a versatile product as it is usable from 10 to 14 carat and for both hand-made and investment cast jewelry. It imparts the desired softness, smooth surface finish and porosity-free finished product. An ideal composition for “invisible” diamond jewelry. recommended practice: 10k 14k application : casting casting alloying temp. : 1040c - 1060c 1050c - 1070c casting temp. : 1020c - 1040c 1030c - 1050c flask temp. [normal cast] : 630c - 660c 630c - 640c flask temp. [stone cast] : 600c - 620c 600c - 620c quenching time : 20 - 25 minutes. 20 - 25 minutes • cast tree cleaning & drying procedure: after primary removal of the investment during quenching, submerge tree in a hot (80-100oc) 50% phosphoric acid solution for 15-20 minutes. Rinse well with cool water to remove remaining investment powder and base metal oxides. Dry with compressed air. • for reusing the castings we recommend 60% fresh carat gold with 40% castings. • for cold working handmade operations it is suggested that after heating to annealing temp(650oc to 750oc) the item should be allowed to cool in air, and not recommended to quench in water.

copper master alloys

Get Price Quote

Being an excellent conductor of electricity, the main industrial usage of Copper is for the production of cable, wire and electrical products for both the electrical and building industries. The construction industry accounts for a large usage of copper in areas such as pipes for plumbing, heating and ventilating, building wire and sheet metal facings. Its applications also include transportation, industrial machinery and white goods sector. At BMC, we deal in copper cathodes, re-melted copper and copper scraps.

Copper & Tin Master Alloys

Get Price Quote

We offer a wide range of Copper & Tin Master Alloys which are significantly used for manufacturing high quality copper rods and extrusions. These products are available in the form of shots, waffle plates, powder and ingots and packed in wooden boxes 500 kg steel drums. These master alloys are also used as grain refiner in automotive pistons.

Gold Master Alloy

15,000 Per Kilogram

1 Kilogram (MOQ)

Copper-Arsenic Master Alloy

760 Per Kilogram

copper master alloys

Get Price Quote

Aluminium Copper master alloy is the alloy of Aluminium and Copper which is used as additive for Copper in Aluminium alloys as a hardener. This alloy is dissolved fast in Aluminium melt and gives maximum recovery of Copper . Aluminium based master alloys which contain the hardener elements in high concentrations, provide a convenient and economical way to add them to Aluminium to achieve desired properties. These master alloys readily dissolved into the liquid Aluminium at lower liquid Aluminium temperatures, thus minimizing dross formation, solubility of hydrogen ,reduced energy consumption and longer furnace life. The chemical composition and physical properties of the Aluminium Copper master alloy is given bellow: panerai replica watches

Gold Master Alloy

10,000 Per Kilogram

1 Kilogram (MOQ)

Legor Alloy

1,850 Per Kilogram

25 Kilogram (MOQ)