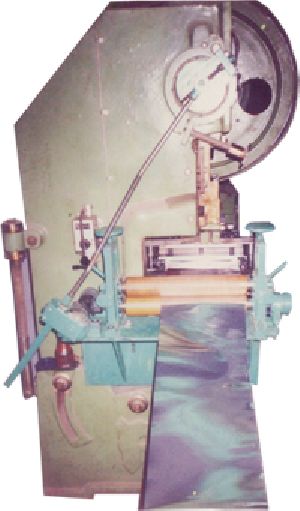

Blanking Circlips and Washer Mechanical Roll Feeder

80,000 Per Piece

1 Piece (MOQ)

Mechanical Gripper Feeder

Get Price Quote

1 set Piece (MOQ)

We are offering mechanical gripper feeder. samay-asia mechanical gripper feeder for stamping press.

Best Deals from Mechanical Feeder

Electro Mechanical Vibrating Feeder

30,000 Per Piece

1 Piece(s) (MOQ)

Mechanical Vibro Feeder

Get Price Quote

1 Piece (MOQ)

We are one of the leading Manufacturers, Suppliers, Distributors of this highly commendable range of Mechanical Vibro feeders

Mechanical Screw Feeder

25,000 - 85,000 Per Piece

1 Piece(s) (MOQ)

UGP-7120FS Straight Line Feeding with Mechanical Auto Feeder with Speed 120PPM

6 - 8 Per Piece

1 Piece (MOQ)

MECHANICAL VIBRATORY FEEDER

Get Price Quote

Feeding capacity from 1 tph to 250 tph. Fitted with unbalance motors. tray width 500mm.to 1500 and length 700mm to 2000mm.

mechanical feeder

99,500 - 110,000 Per Piece

1 Piece (MOQ)

mechanical feeder

Get Price Quote

The new Syntron® Crusher Loading (Mechanical) Feeder is a traditional mechanical style vibratory feeder with built-in feeder and a Rotating Feed Distributor (RFD). The Crusher Loading Feeder retains the high reliability and robust design of FMC Syntron mechanical feeder and the peripheral discharge, which has its origins in the distribution of snack foods and cereals onto radial scales, enabling equal distribution of fine and coarse product. The trough is fully lined to account for wear, and it is suspended by the same method as traditional vibratory feeders. The suspension framework can be mounted on a trolley that can simply be moved out of the way for crusher maintenance. The Crusher Feeder is used extensively as mining equipment to handle materials such as coal and aggregate to supply cone crushers and gyratory crushers.

Electro Mechanical Vibrating Feeder

Get Price Quote

we are the renowned electromechanical vibrating feeder manufacturer, exporter and supplier in chennai, tamil nadu. This electromechanical vibrating feeder is of high frequency reciprocating machine to convey bulk material. The continuous flow rate helps electromechanical vibrating feeder in conveying material from storage to processing or between processes. This electromechanical vibrating feeder can help in handling all kinds of material even if they are hot, lumps, damp, dusty or abrasive for various functions. Our electromechanical vibrating feeder is used for different processes like washing, drying, cooling etc. provided with base mounted over hangingsupplied with combined single motor drivecan be customized.

electro mechanical feeders

Get Price Quote

STAR TRACE" Heavy -Duty Vibro Motor Powered Vibratory Feeder is a High frequency reciprocating machine of heavy duty capable on conveying bulk material from storage to processing or between processes at a continuous controlled rate of flow. Thus Vibrating feeders are used in processing industries for handling all types of materials such as hot, damp, lumps, dusty or abrasive for various functions like flow material from storage, proportioning and blending, packaging, mixing, weighing, sprinkling, screening, scalping, crushing, washing, drying, heating, cooling, dusting, spreading, batching and etc. STAR TRACE Heavy - Duty Vibrating Feeders can be supplied with base mounted over hanging or combined single motor drive or with twin dual or Dual twin motor drives or with multiple drives to serve as vibrating conveyors. These feeders are having a tray mounted on thedrive units. This drive unit is located beneath the tray. STAR TRACE Vibratory Motors are used in Vibro feeders are totally enclosed 3 Phase, squirrel cage induction motors with adjustable, eccentric weights mounted at both the ends of the shaft to set up vibrations during rotaion. The design of shaft and the selection of bearings has been carefully done to withstand heavy radial loads. Two identical motors mounted parallel to each other on a right and left, which is free to move in all directions, will produce to each other on a right and left, which is free to move in all directions, will produce linear vibrations. When connected for contra - Rotaion so know this principle is adopted for handling large bulky material in large feeders. This Vibratory motor stator frame is fabricated in steel or cost in spheroidal graphetic Iron and the windings / connections are properly reinforced to with stand the heavy vibrating forces. Vibratory motors can be adopted for conveyors and feeders for handling large quantities of materials is moved by linear force along with conveyor. Usually vibratory motors are fixed at an angle between 30o to 45o to the plane of the conveyor. This gives the system both upward and forward motion and horizontal vibrations to the tray which ensures a free, smooth, uniform and volumetric flow to the material that is fully variable.

mechanical feeder

Get Price Quote

1 Piece (MOQ)

we Offers mechanical feeder, feeder for power press.

Mechanical Gripper Feeders

Get Price Quote

Standard transmission including one 900 gear box, one connecting shaft (length must be adapted to the press dimensions) and one rubber coupling. Transmission for speed over than 350 strokesmin including one 900 gear box and its support, one connecting shaft (length must be adapted to the press dimensions), one flexible coupling and one angle setting coupling. Cascade roll basket to hold the strip on the entry side. Mounting bracket to be fixed to the press

Mechanical Roll Feeder

Get Price Quote

Known to have unmatched quality, our mechanical roll feeder for power presses are available in the range of 2 roll feeder. These are designed to provide maximum possible output in the smallest time frame. To ensure their long service life, the feeders incorporate wear resistant roller. The product also has small turning inertial which enables fast stopping at any stage further ensuring feed precision. Main application area of our quality mechanical roll feeder for power presses are rolling metals coils, Aluminium and Brass.

Mechanical Gripper Feeders

Get Price Quote

Accurate and easy pitch adjustment. Accuracy to the tume of ± 25microns, obtainable with piloting. The Grippers are made out of carbide ot give life ling service. All rotating parts are fitted with antifriction bearings to give long life and reduced maintenance. High speed of upto 650 strokes Features Accurate and easy pitch adjustment. Accuracy to the tume of ± 25microns, obtainable with piloting. The Grippers are made out of carbide ot give life ling service. All rotating parts are fitted with antifriction bearings to give long life and reduced maintenance. High speed of upto 650 strokes per minute. Roller Cam for Pilot release setting, which gives great precision in adjustment of the fixed gripper. Micrometer pitch setting arrangement provided. Silent in operation - no air required. Trouble free in operation. Mechanically synchronized with the press thus avoiding feeding mismatch at high speeds. Drive from press crankshaft to the Feeder is fitted with an overload safety coupling. Hardened gears provided in the right angle gear box for long life. Stock buckling guides for thin material. Easy setting for strip thickness. Accessories Standard transmission including one 900 gear box, one connecting shaft (length must be adopted to the press dimensions) and one rubber coupling. (SUKU/11). Transmission for speed over than 400 strokes/min including one 900 gear box and its support, one connecting shaft (length must be adopted to the press Dimensions), one flexible coupling and one angle setting coupling. Cascade roll basket to hold the strip on the entry side. Mounting bracket to be fixed to the press.

mechanical feeder

Get Price Quote

We are one of the best leading supplier of MECHANICAL FEEDER

Vibratory Feeders Electro Mechanical

Get Price Quote

JAYKRISHNA manufacturers vibratory motor base feeders, which utilize the force Set up by two synchronized counter rotating, heavy-duty vibrator motors. At two points in each complete revolution, the centrifugal forces of each vibrator coincide, resulting in a linear force. Our feeders are custom built to meet any application needed. Feeders are built rugged to produce the consistent flow rates and trouble free operation needed for efficient processing. The feeder can be designed wither base mounted or suspension/ hanging type. Motorised Vibratory Feeder Technical Specification : The Mechanical Vibratory Feeder consist of a tray made out of Mild Steel. The body housung of the Vibrator is made from heavy duty M.S. Plates. As the motor get energised the Vibration sets the material in motion. The Vibration of the feeder will be controlled with the help of adjusting the loads of the motor. The Feeder will be mounted on heavy duty spring Bar/Brackets or Base Mounting. Application Liners can be provided for special application e.g. Feeding of ORE & pellets in the blast furnace. Enclosed body for feeder can be manufacturer for extracting minerals for storage bins and conveying to kilns

Mechanical Gripper Feeder

Get Price Quote

Offers mechanical gripper feeder. Standard features round guides with linear ball bushings. capability to mount to any type of press. transmission through bevel gear box and cardian shaft from the press. lubrication oiling by grease nipple. accuracy of +-0.025mm with mechanical pilot synchronisation easy setting of pitch length. all adjustments are easily reachable. quick opening of the gripper for the strip insertion. release of the fixed gripper for die piloting in order to obtain & accurate positioning at high speed. adjustment for various thickness by means f knuckled knobs placed at the upper part of the feed. standard transmission for speeds uptill 300 strokes per minute including gear box, transmission shaft and rubber coupling. mounting stand bracket. cascade roll basket.

mechanical feeder

Get Price Quote

The chute is designed to prevent the waste from being compacted and allows for a uniform distribution across the grate. This is the basic requirement to obtain an even combustion.The feeder chute is a well proven design. All parts of the feeding device exposed to any heat effect are water cooled. The whole mechanical feeding system is located in an airtight shell, ensuring no leakages of dust, waste material or gases. Thus any emissions into the environment are prevented.

Mechanical Gripper Feeder

150,000 Per Piece

5 Piece (MOQ)

Mechanical Gripper Feeders

Get Price Quote

Features Accurate and easy pitch adjustment. Accuracy to the tume of ± 25microns, obtainable with piloting. The Grippers are made out of carbide ot give life ling service. All rotating parts are fitted with antifriction bearings to give long life and reduced maintenance. High speed of upto 650 strokes per minute. Roller Cam for Pilot release setting, which gives great precision in adjustment of the fixed gripper. Micrometer pitch setting arrangement provided. Silent in operation - no air required. Trouble free in operation. Mechanically synchronized with the press thus avoiding feeding mismatch at high speeds. Drive from press crankshaft to the Feeder is fitted with an overload safety coupling. Hardened gears provided in the right angle gear box for long life. Stock buckling guides for thin material. Easy setting for strip thickness. Accessories Standard transmission including one 900 gear box, one connecting shaft (length must be adopted to the press dimensions) and one rubber coupling. (SUKU/11). Transmission for speed over than 400 strokes/min including one 900 gear box and its support, one connecting shaft (length must be adopted to the press Dimensions), one flexible coupling and one angle setting coupling. Cascade roll basket to hold the strip on the entry side. Mounting bracket to be fixed to the press.

Electro Mechanical Feeder

Get Price Quote

We are offering electro mechanical feeder. we develop heavy duty vibro motor powered vibratory feeder that is a high frequency reciprocating machine of heavy duty, capable of conveying bulk material from storage to processing or between processes at a continuous controlled rate of flow. Vibrating feeders are used in processing industries for handling all types of materials such as hot, damp, lumps, dusty or abrasive for various functions like flow of material from storage, proportioning and blending, packaging, mixing, weighting, sprinkling, screening, scalping, crushing, washing, drying, heating, cooling, dusting, spreading, batching and etc. We supply heavy-duty vibrating feeders with base mounted over hanging or combined single motor drive or with twin dual or dual twin motor drives or with multiple drives to serve as vibrating conveyors. These feeders are having a tray mounted on the drive units. This unit is located beneath the tray.

Mechanical Gripper Feeder

Get Price Quote

Mechanical Gripper Feeder, Press Automation Equipment, Pneumatic Feeder

Mechanical Gripper Feeder

Get Price Quote

Mechanical Gripper Feeder, Pneumatic Feeders, Material Handling Equipments

mechanical feeders

Get Price Quote

mechanical feeders, Cylinders, Pneumatic Air Feeder

Electro Mechanical Feeder

Get Price Quote

Electro Mechanical Feeder, Bin Vibrator, electro magnetic feeder

electro mechanical feeders

Get Price Quote

electro mechanical feeders, Magnetic Filters, Magnetic Pulley

Push Pull Mechanical Feeder

Get Price Quote

Push Pull Mechanical Feeder, Mechanical Roll Feeder

Mechanical Vibro Feeders

Get Price Quote

Mechanical Vibro Feeders, Pan Conveyors, Pre-Assembly, Airlift

mechanical feeders

Get Price Quote

mechanical feeders