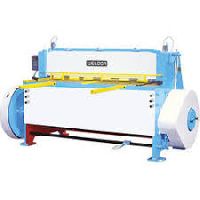

Under Crank Mechanical Shearing Machine

Get Price Quote

We are one of the leading Under Crank Shearing Machine Manufacturers. These machines are designed through structural analysis technique which ensures scratch free production, high accuracy and repeatability. Interlock Shearing Machine which we manufacture are the most trusted and reliable machines in the market, being one of the prime Shearing Machine Supplier in India we know that quality assurance and customer satisfaction is a key to success for any business to grow and succeed. Click Here For Technical Specifications

Mechanical Undercrank Shearing Machine

Get Price Quote

note : dimensions, design, weight, & specifications can be change as market demands or further improvement of machine without notice..

Best Deals from Mechanical Under Crank Shearing Machine

Mechanical Under Crank shearing Machine

175,000 Per Piece

1 Piece (MOQ)

Mechanical Under Crank shearing Machine

Get Price Quote

Frame is so designed as to take load during cutting operation. Its interlocked design supports the bed. The Ram is guided throughout its length by accurately machined guideways. Drive mechanism is so designed as to transmit maximum power. It consists of Gear, Pinion & Fly Wheel. Fly Wheel made of high grade C. I. provides sufficient energy during cutting operation. Each moving part is provided with lubrication through hand operated lubrication pump for smooth operation.

Mechanical Under Crank shearing Machine

250,000 Per Piece

1 Piece(s) (MOQ)

Mechanical Under Crank shearing Machine

Get Price Quote

Rigid Steel Frame of Kishan shears are optimally designed to avoid weak sections and is of interlocked design. The Ram is guided throughout its length by accurate machined guide ways ensuing proper clearance and clean out.Revolvig Key Cluth Iinked with the Main Gear engages every time when Fool Pedal Is pressed. Drive provided through V-Belt & all journals are fitted in Gun Metal Beanngs. Brake is adjustable and incorporated on end of Crack Shaft.

Under Crank Mechanical Shearing Machine

Get Price Quote

Under Crank Mechanical Shearing Machine

Get Price Quote

They are commonly used for cutting large sheets, bars and plates of metallic and non-metallic materials into different shapes. Our machines are engineered for rapid and accurate cutting. We supply modern, tough and long lasting shearing machines. The key features include higher safety, low maintenance and optimum productivity.These machines comply with standard quality control regulations. Our shearing machines are made to minimize material wastage. They are crafted for continuous and repeated output. We provide diverse models with various technical specifications. Shearing machines are useful in automobile, printing, food processing, engineering, electronic, plastic, wood working, electrical, construction and many other industries.

Mechanical Under Crank shearing Machine

Get Price Quote

KNTM Brand Mechanical Shears fabricated from IS-2062 graded. Rolled steel plates. Table and cutting beam are deeply reinforced and fines machine after stress reliving. The interlocked design put the direct support to frame. Thus frames are strain free and eliminate welds at load support. Thus the accuracy of the machine is never disturbed. FRAME CONSTRUCTION Mechanical Under Crank Shearing machine Frame fabricated from IS-2062 graded. Rolled steel plates. Table and cutting beam are deeply reinforced and fines machine after stress reliving. The interlocked design put the direct support to frame. Thus frames are strain free and eliminate welds at load support. Thus the accuracy of the machine is never disturbed. BED Super strong bed of closed box type construction, Street relieved in a furnace, forms a rigid backbone for the shear and a solid backing for the lower knife. Dovetail slots in front of the bed are provided for front gauge. Slots on top of bed area also provided for machined pas across the bed for convenient setting of front gauge brackets any desired spacing. Depressions in the top at the bed provide ample clearance for fingers in handling sheets narrower than the bed. UPPER BEAM Ram is also of solid steel plates, carrying the upper knife. Its minimum weight ensure lesser load on the bearings, The upper beam moves in flat heat treated steel guide plates to avoid plates to avoid deflection, for smooth running and maintain the accurate straightness of the upper knife. HOLD-DOWN MECHANISM Solid clamping by powerful spring loads hold down is one of the reasons for accuracy in our shears. Heavy uniform pressure is applied along the full length of the work piece, preventing slippage regardless of versions in thickness. Hold down pressure in easily adjustable for clamping soft material. Different thickness of material can be cut without future adjustment with consistently accurate and burr free results. ROLLING KEY CLUTCH Made of alloy steel for positive engagement and continuous operation having three key ways. Single rolling key system is incorporated in the machine ensuring easy and efficient working of the machine. SHEAR KNIVES Knives are manufactured strictly as per standard material of D2 HCHCr. Every step from designing metallurgical specifications, heat treatment, grinding and inspection is carefully controlled. The blades are standards are standardized and are easily replaced. ACCURATE GAUGING The Rigid and accurate construction of the back gauge provided with the machine allows consistency in the width of sheets being cut. LUBRICATION Single shot lubricator provides oil to all the lubrication points, when necessary. Thus, all bearing parts and guide surface etc. DRIVE Drive through V-belts on flywheel and reduction gears are made of steel, hob cut for the smooth running and longer life.

Mechanical Under Crank shearing Machine

Get Price Quote

Owing to our speedy distribution network, we are capable to render quickly and hassle free deliveries. We have a team of quality inspectors who check the entire lot of raw material on several counts, prior to procurement. Thus, quality of the finished products is never fortified.

Mechanical Under Crank shearing Machine

Get Price Quote

we are one of the leading under crank shearing machine which is a statement in itself, these are designed through structural analysis technique which ensures scratch free production, high accuracy and repeatability. Interlock shearing machine which we manufacture are the most trusted and reliable machines in the market. Being one of the prime shearing machine supplier in india we know that quality assurance and customer satisfaction is a key to success for any business to grow and succeed.

Mechanical Under Crank shearing Machine

Get Price Quote

HP Singh Machinery Pvt. LTD is one of the leading expertises in manufacturing and exporting Mechanical Under Crank Shearing Machine. We provide these machines in the market at very economical price. Shearing are available in Capacities (size) of 4 feet 5 6 8 10 12 feet & 13 feet length thickness of machine is 0.100 mm up to 4 mm capacities, rolling key clutch, spring loaded mechanical hold down pads, increased productivity & reliability.

Mechanical Under Crank shearing Machine

Get Price Quote

We have in store for our clients a wide range of Mechanical Under Crank Shearing Machines. The high-grade raw material is sourced from the authentic vendors of the market to manufacture these machines in compliance with the set industry standards. The Mechanical Under Crank Shearing Machines are offered in various technical specifications to meet the variegated demands of our customers.

Mechanical Under Crank shearing Machine

Get Price Quote

We are offering mechanical under crank shearing machine etc. We are leading manufacturer of mechanical under crank shearing machine,please send us your requirement detail.

MECHANICAL SHEARING - UNDER CRANK

Get Price Quote

Mechanical Under Crank shearing Machine

Get Price Quote

We are leading supplier of huge range of Mechanical Under Crank Shearing Machine.

Mechanical Under Crank shearing Machine

Get Price Quote

Our Mechanical under Crank Shearing Machine consists of a strong bed, of closed box type, that forms a rigid backbone best for shearing and support for the lower knife. It achieves very high accuracy during operation. These mechanical shearing machines are available with different specifications as per standardShears fabricated from IS Graded, Rolled steel plates. Table and cutting Beam are deeply reinforced and finely machined after stress relieving. The interlocked design put the direct support to frame, Thus frame is strain free and eliminate welds at load supports. Therefore the accuracy of the machine is never disturbed, Super strong bed of closed box type construction, stress relieved in a furnace, forms a rigid backbone for the shear and a solid backing for the lower Knife. Dovetail slots in front of the bed are provided for front gauge. Slots on top of bed are also provided for machined pad across the bed for convenient setting of front gauge brackets at any desired spacing.Depressions in the top of the bed provide ample clearance forfingers in handling sheets narrowerthan the bed.

Mechanical Under Crank shearing Machine

Get Price Quote

Shearing Machines have been designed and developed through structural analysis technique for continuous production, accuracy and repeatability having the following main features: Spring loaded mechanical Hold down pads hold the sheet securely, to avoid slipping and bowing resulting in clean square cuts. Holddown units are provided with oversize pads to avoid impressions on sheet metal on request.

Mechanical Under Crank shearing Machine

Get Price Quote

Rigid, Interlock designed, heavily welded construction of MS plates and sections to take full load with minimum deflection. The arm is guided throughout its length by fiber guideways ensuring proper clean cut. A rigid clutch mechanism is provided for giving continuous strokes for production. The spring loaded Mechanical Hold Down maintains a positive and uniform pressure along the full length of work piece avoiding slipping and bowin of sheet resulting a clean square cut.

Mechanical Under Crank shearing Machine

Get Price Quote

WELDOR Shearing Machines have been designed & developed through structural analysis technique of continuous production accuracy and repeatability.1. Frame: Rigid steel frame of Weldor Shears are optimally designed to avoid weak sections at load supports an is of interlocked design. The ram is guided throughout its length by accurate machined guideways ensuring proper clearance and clean cut.2. Hold-down system: Spring loaded mechanical Hold down pads hold the sheet securely, to avoid slipping and bowing resulting in clean square cuts. Hold down units are provided with oversize pads to avoid impressions on sheet metal on request.3. Knives: Weldor Shears are provided with high quality single segment (HcHcr) knives for longer tool life. ease in assembling of knife reduces down - time. the knife blades are four edged.4. Lubrication: All bearing parts and guide surfaces are lubricated through hand-operated lubrication system.

Mechanical Under Crank shearing Machine

Get Price Quote

The machinery is constructed with a rigid steel frame with an interlocked design, created to avoid weak sections. In order to ensure proper clean cut and clearance, ram is guided throughout the length with ground guide ways. The hold down system of under crank shearing machine is loaded with springs and holds sheets to avoid slippery and bowing result in a clean square cut. The finger guard is fitted in front of hold down for the safety of the operator. The four edge, single and segmentally high carbon, chromium steel blades are suitable for cutting and longer use. The bearing parts and guide surfaces of the machine are lubricated by the centralized hand operated lubrication system. Mechanical Back Gauge gives readings of the distance between back gauge and shear through a scale in order to avoid errors and maintenance of encountered electronic equipment. The Accessories list of Mechanical Under Crank Shearing Machine includes Electrical System consisting of motor & Control Panel of Starter, Gear and wheel guard, V-Belts, Hand operated back gauge, Manual Lubrication System, T-slot front gauge, Front scale gauge, instruction Manual, Hydraulic hold-down system, Automatic lubrication system, Ball roller or Ball Transfer, Foundation bolts, and Extension squaring arm.

Mechanical Under Crank shearing Machine

Get Price Quote

For the diverse requirements of our clients we are involved in offering a wide assortment of Shearing Machine. We offer them to our esteemed patrons after checking them on several parameters under the vigilance of our quality controllers. These products are widely used for cutting to size and cater diverse requirements of the clients.

Under Crank Mechanical Shearing Machine

Get Price Quote

Mechanical Under Crank shearing Machine

Get Price Quote

Under Crank Shearing Machine is suited for cutting to size general purpose unalloyed steel. Structural steel sheets up to 4mm thickness with high productivity. Each machine, designed to the most accurate of efficiency, offers outstanding operational performance dimensional accuracy telling on high output and dependability. Frame Construction:Guillotine shearing fabricated from Is-226 Grade. Rolled steel plates. Table cutting Beam are deeply reinforced and fines machine after stress reliving. The interlocked design put the direct support to frame. Thus frames are strain free and eliminate welds at load supports. Thus the accuracy of the machine is never disturbed. BED: Super strong bed of closed box type construction. Stress relieved in a furnace. Forms a rigid backbone for the shear and a solid backing for the lower knife. Dovetail slots in front of the bed are provided for front gauge. Slots on top of bed are also provided for machined pad across the bed for convenient setting of front gauge brackets at any desired spacing. Depressions in the top of the bed provide ample clearance for fingers in handling sheets narrower than the bed. Upper Beam: Ram is also of solid steel plate, carrying the upper Knife. Their minimum weights ensure lesser load on the bearings. The upper beam moves in flat heat treated steel guide plates to avoid deflection, for smooth running and maintain the accurate straightness of the upper knife. Hold-Down Mechanism: Solid clamping by powerful spring loaded hold down is one of the reasons for accuracy in our shears. Heavy uniform pressure is applied along the full length of the work piece, preventing slippage regardless of variations in thickness. Hold down pressure is easily adjustable for clamping soft material. Different thickness of material can be cut without further adjustment with consistently accurate and burr free results. Rolling Key Clutch: Made of alloy steel for positive engagement and continuous operation having three key ways. Single rolling key system rolling key system is incorporated in the machine ensuring easy and efficient working of the machine. Shear Knives: Knives are manufactured strictly as per standard material of HCHCr/OHNS. Every step from designing metallurgical specification, heat treatment, Grinding and inspection is carefully controlled. The blades are standardized and are easily replaced. Accurate Gauging: The rigid and accurate construction of the back gauge provided with the machine allows consistency in the width of sheets being cut. Lubrication: Single shot lubricator provides oil to all the lubrication points, where necessary. Drive: Drive is through V-Belts on flywheel and a reduction gears are made of steel, hob cut for smooth and longer life.

Mechanical Under Crank shearing Machine

Get Price Quote

Shubhampress Automation Mechanical Under Crank Shearing Machine have been designed and developed through structural analysis technique for continuous production, accuracy and repeatability. Shubhampress Automation Mechanical Under Crank Shearing Machine have been designed and developed through structural analysis technique for continuous production, accuracy and repeatability. Frame :Rigid steel frame of Shubhampress Automation shears are optimally designed to avid weak sections at load supports and is of interlocked design. The ram is guided throughout its length by hardened and ground guide ways ensuring proper clearance and clean cut. Hold-Down System : Spring loaded mechanical hold-down pads hold the sheets securely to avoid slipping and bowing result in clean square cut. Hold down units are provided with oversize pads to avoid impression on sheet metal. Blades : Shubhampress Automation shear are provided with Four Edge, single & segment ally High Carbon, Chromium Steel Blades suitable for M.S. &.S.S. Cutting and Extra long life. Lubrication : All bearing parts and guide surfaces are lubricated Through centralize hand-operated lubrication system. Mechanical Back Gauge : This is a standard equipment provided on all Shubhampress Automation Shears. Scale on the back gauge gives instantaneous reading of distance between shear and back gauge, thus avoiding errors and maintenance encountered in electronic equipment. Finger Guard : Fitted in front of hold-down for operator safety without obstructing viewing. Standard Equipment : Electrical System consisting of motor & Control Panel of Starter, Gear and wheel guard, V-Belts, Hand operated back gauge, Manual Lubrication System, T-slot front gauge, Front scale gauge, instruction Manual Optional Equipment : Hydraulic hold-down system, Automatic lubrication system, Ball roller or Ball Transfer, Foundation bolts, Extension squaring arm. Note :Electrical and Blades are not under Warranty. Mechanical Guillotine Shearing Machines : "Shubhampress Automation" brand mechanical shearing machines are available in two versions i.e. under crank and over crank having capacities starting from 500 mm to over 3000 mm and with thickness varying from 2 to 12mm. Machines incorporate several standard, optional features like hold down systems- mechanical, hydraulic manual or auto lubrication systems- mechanical back gauge; ball roller or ball transfers; extension squaring arm finger guard etc. Special versions can also be offered to meet specific production requirements.

Mechanical Under Crank shearing Machine

Get Price Quote

The spring loaded mechanical hold down pads hold the sheet securely, to avoid slipping and bowing resulting in clean square cuts. Hold down units are provided with oversize pads to avoid impressions on sheet metal on request.DRIVE : Motor, mounted on an adjustable platform, drives the large, cast iron fly wheel through v-belts. The power is Further transmitted to the fly wheel shaft through steel pinion and main gear box and than transmitted to main gear. Gun-Metal bushes are provided all the rotating parts .CLUTCH : Rollin key clutch is linked with the main gear and engages every time when the foot switch is pressed.BRAKE :Spring tensioned braked fitted at the end of the crank shift to damp inertia.

Mechanical Under Crank shearing Machine

Get Price Quote

SHAILESH shearing machines have been designed and developed through structural analysis technique for continuous production, accuracy and repeatability.Rigid steel frame of SHAILESH shears are optimally designed to avid weak sections at load supports and is of interlocked design. The ram is guided throughout its length by hardened and ground guide ways ensuring proper clearance and clean cut.

Mechanical Under Crank shearing Machine

Get Price Quote

Mechanical Under Crank Shearing Machine fabricated from IS-2062 graded rolled steel plates table and cutting beam are deeply reinforced and fines machines after stress reliving. The interlocked design put the direct support to frame. This frame is strain free and eliminates welds at load supports. Thus the accuracy of the machine is never disturbed.Pneumatic Clutch With Photo Safety Curtains,Electrical Motor, Starter & V-Belt,Four Edge Interchangeable Shear Blade Operation & Maintenance Manual Book

Mechanical Under Crank shearing Machine

Get Price Quote

We are offering mechanical under crank shearing machine.

Mechanical Under Crank shearing Machine

Get Price Quote

Mechanical Under Crank shearing Machine, H Type Power Press Machines