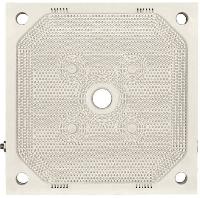

membrane filter plate

Get Price Quote

Being a client-centric firm, we are dedicatedly involved in making available quality Membrane Filter Plate.For the utmost convenience of our customers, we ensure that the transaction is done only under the stern supervision of experts and professionals. This makes our payment procedures more secured and transparent. Advantages of Membrene Filter Plates Short filtration Cycles Short Washing Cycles Detachable Membrane High Elasticity of Membrane Even in the empty Chamber Large Cross-sectional area of Filtrate Outlet

Membrane Filter Plates

Get Price Quote

The initial operation of a membrane filter press is identical to that of its recessed chamber counterpart. However once the filtration cycle is complete and final filtration pressure is achieved the feed into the filter press is stopped. At this point the plates within the Filter Press can be inflated using either air or hydraulic pressure to exert a mechanical force on the filter cake retained in the chamber. The effect of the squeeze is to physically compress the filter cake and force out additional moisture held within the cake giving a drier end result.

Best Deals from Membrane Filter Plates

Membrane Filter Plates

25,000 - 150,000 Per Piece

10 Piece(s) (MOQ)

Membrane Filter Plates

Get Price Quote

The Membrane filter plates are the technological development of the recessed plates. These elements come with variable chamber depth which is adjusted depending upon the filterability and quality of slurries to be treated. Mixed pack membranes are the most common & cost effective configuration where the membrane and recessed plates are set alternatively so every second plate is provided with flexible and replaceable filter face of rubber on both the side. This configuration allows variable chamber depth through membrane squeezing. These plates are mainly used to increase the cake dryness (reduce moisture content), shorten filtration, effective washing and discharge time and they are achieve by inflating the flexible membrane diaphragm filter face, contrary to conventional plates. For inflation of membrane generally water or air pressure is used by pumping in the squeezing chamber. The replaceable membrane are either from Rubber or EP family which has great advantage of elasticity gives extreme deflection of membrane so the final cake receive the consistent high dryness. Due to Squeezing process the Membrane Plates offers following advantages.– Reduction in Moisture content in the final filter cake– Reduction in Filtration, Washing as well discharge time.– Reduction of washing liquid consumption due to more homogeneous cake structure.– Increased Uniformity in dewatering of the filter cake.– Improvement in cake release from the filter press.– Saving in filtration process cost and time. Membrane plates are available with center, top center and corner feed designs for up to 16 bar operating pressure.

Membrane Filter Plates

Get Price Quote

This Membrane Filter Plates operate to a feed pressure of up to 7 bar and the squeezed pressure can be up to 15 bar. PANAMA ENGINEERING can manufacture special plates for special needs for high feed pressures or low squeeze pressures. PANAMA ENGINEERING manufactures membrane plates with thermoplastic or 100% polypropylene.

Membrane Filter Press Plates

Get Price Quote

Membrane Filter Plates

Get Price Quote

the membrane filter plates are the technological development of the recessed plates. These elements come with variable chamber depth which is adjusted depending upon the filterability and quality of slurries to be treated. Mixed pack membranes are the most common & cost effective configuration where the membrane and recessed plates are set alternatively so every second plate is provided with flexible and replaceable filter face of rubber on both the side. This configuration allows variable chamber depth through membrane squeezing. These plates are mainly used to increase the cake dryness (reduce moisture content), shorten filtration, effective washing and discharge time and they are achieve by inflating the flexible membrane diaphragm filter face, contrary to conventional plates. For inflation of membrane generally water or air pressure is used by pumping in the squeezing chamber. the replaceable membrane are either from rubber or ep family which has great advantage of elasticity gives extreme deflection of membrane so the final cake receive the consistent high dryness. due to squeezing process the membrane plates offers following advantages.- reduction in moisture content in the final filter cake- reduction in filtration, washing as well discharge time.- reduction of washing liquid consumption due to more homogeneous cake structure.- increased uniformity in dewatering of the filter cake.- improvement in cake release from the filter press. - saving in filtration process cost and time. membrane plates are available with center, top center and corner feed designs for up to 16 bar operating pressure.

Membrane Filter Plates

Get Price Quote

High dry solids content in the filtration cake (higher than with the chamber filter press) => lower costs of transport and storage of the cake Shortened filtration cycle – compared to the chamber filter press it is possible to perform more filtration cycles over the same time. adaptability to the changing filtration conditions – e.g. differences in the suspended solids concentrations in the fed suspension Possibility of efficient washing of the filtration cake– controlled pressure of membranes ensured continuous flow of washing liquid through the cake. This ensures that the substances are washed out of the cake and the required purity is ensured. Smaller dimensions of the filter press given the same performance compared to the chamber filter press

Membrane Filter Plates

Get Price Quote

Because of its simplicity and flexibility, the chamber Filter Press has been widely applied in clarification and dewatering applications. Membrane Filter Press technology is gaining increased acceptance because it reduces subsequent processing or disposal costs for filter cake.

Membrane Filter Plates

Get Price Quote

Membrane filter press plates utilize an impermeable, flexible member attached to the filter press plate core. This terminology should not be confused with sub micron "membranes" used in ultra filtration or reverse osmosis. In filter presses, a membrane, also called a diaphragm, is designed to inflate by compressed air or pressurized water to squeeze residual moisture out of the formed filter cake. Polypropylene membrane plates supplied in FILTER PRESS INDIA Filter Presses have been in use for more than ten years with significant success. Theses plates are currently in many severe applications - some operating two cycles per hour, 24 hours per day for two years - tens of thousand of cycles without failure.

Membrane Filter Plates

50 - 150 Per Nos

10000 Piece (MOQ)

Membrane Filter Plates, Insulation Material, Conditioning Chamber

membrane filter plate

Get Price Quote

membrane filter plate, Geotextiles, Geobags, water filter fabrics

membrane filter plate

Get Price Quote

membrane filter plate, Fully Automatic Filter Press, Filter Plate

Membrane Filter Press Plates

Get Price Quote

Backed by a team of experienced professionals, we are manufacturing, exporting and supplying an optimum quality Membrane Filter Press Plates. These plates are used in filter that generates higher filtration productivity through reduced dryer cake, cycle times and more efficient washing.

Membrane Filter Plates

Get Price Quote

Membrane Filter Plates, Ozone Air Purifier With HEPA Filters, HEPA Filters

Membrane Filter Plates

Get Price Quote

Membrane Filter Plates, Power Packs, Filter Press Cloth

Polypropylene Membrane Filter Plate

Get Price Quote

Polypropylene Membrane Filter Plate, Filter Feed Pumps, drain cock

Membrane Filter Plates

Get Price Quote

Membrane Filter Plates, Manually Operated Filter Press, Oil Squeezing Press

membrane filter plate

Get Price Quote

membrane filter plate, Waste Reduction, Electrodeionization, uf membranes