Sand Screening Machine

Get Price Quote

We are offering sand screening machine. technical features: manual / power capacity (dry sand): 2 cu. M. / hour power : 1h.p. Electric motor transmission:oil filled reduction gear box and "v" groove pulley with bealt

Linear Rectangulare Vibrating Screening Machine

Get Price Quote

1 Piece (MOQ)

Best Deals from Mining Equipment Accessories

vibro screening machine

40,000 - 400,000 Per

Technical specification:-The heart of the Vibroscreen is its special heavy duty, Robust Motor, having out of balance weight at top & bottom. By changing their lead angle, various spiral-screening patterns are obtained to suit different application.It is also called Vibro energy separator.

Screening Machine

Get Price Quote

1 Piece (MOQ)

Sand Screening Machine

64,000 Per Unit

1 Unit (MOQ)

Mining Spare Parts

Get Price Quote

PU Bucket Panels

2,000 - 6,000 Per piece

Polyurethane Bucket Panels by Vam Poly Plast Pvt Ltd - Durable Solutions for Material Handling Vam Poly Plast Pvt Ltd, headquartered in Hyderabad, India, is a trusted manufacturer of Polyurethane Bucket Panels. These panels are expertly engineered to provide durable solutions for material handling, ensuring exceptional performance and longevity in various industrial applications. Key Features and Benefits High-Quality Polyurethane Construction: Our Bucket Panels are meticulously crafted from top-tier polyurethane material, ensuring exceptional quality and reliable performance. Impressive Wear Resistance: These panels offer impressive wear resistance, making them ideal for applications involving abrasive materials, thus extending their service life. Enhanced Material Flow: Vam's Polyurethane Bucket Panels facilitate smooth material flow, optimizing the efficiency of material handling equipment. Reduced Downtime: The robust polyurethane material contributes to minimal downtime, reducing maintenance frequency and operational disruptions. Customization Options: We provide customization in terms of size and specifications, allowing you to select the perfect Bucket Panel for your specific material handling application. Applications in Focus Our Polyurethane Bucket Panels excel in various material handling applications, including: Mining and Quarrying: Improve the durability and efficiency of material handling equipment in mining and quarry operations. Agriculture: Enhance the performance of agricultural machinery for crop handling and storage. Construction: Optimize the material handling process at construction sites for increased productivity. Connect with Us: If you're ready to elevate your material handling efficiency with our Polyurethane Bucket Panels, our experienced team is ready to assist you. Contact us for comprehensive technical details, customized solutions, and expert guidance tailored to your specific material handling needs. Choose Vam Poly Plast Pvt Ltd for dependable Polyurethane Bucket Panels that offer durability and efficiency, ensuring optimal performance in your industrial material handling operations. We're committed to providing solutions that make a difference.

Vibratory Sand Screening Machine

Get Price Quote

1 Piece (MOQ)

We are one of the leading fabricators of superior quality Vibratory Sand Screening Machine. Manufactured using finest grades of raw material, these vibratory sand screening machine is available in 1350-L x 1150-W x 1190-H size and widely acknowledged across construction and allied industries. Provided with solid rubber wheel for easy mobility.

Cylindrical Screening Machine

400,000 Per Piece

1 Piece(s) (MOQ)

Compost Screening Machine

Get Price Quote

Vibro Screening Machines

45,000 - 375,000 Per Nos

1 Piece (MOQ)

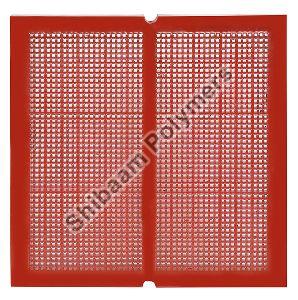

PU Modular Screen

Get Price Quote

Used for Cement Plants Steel Plants Mining Industry Power Plants Mineral Beneficiation Plants Coal Washeries Applications Secondary Tertiary & Final Screenings

Polyurethane Screen

Get Price Quote

100 Kilogram (MOQ)

Trommel Screening machine

1,500,000 Per Piece

1 Piece (MOQ)

Vibrating Screening Machine

1,500,000 - 6,000,000 Per piece

1 Unit (MOQ)

Sand Screening Machine

Get Price Quote

Bamboo Board Particle Screening Machine

Get Price Quote

1 piece (MOQ)

Introducing the “Bamboo Board Particle Screening Machine” by Prashant Bamboo Machines – a reliable and efficient solution for separating particles and impurities from bamboo boards during the manufacturing process. Our screening machine is specifically designed to streamline the particle screening process, ensuring clean and high-quality bamboo boards. Why Choose Prashant Bamboo Machines? Industry Expertise: With years of experience in the bamboo processing industry, we possess in-depth knowledge of the specific requirements and challenges faced by manufacturers. Our machines are designed to meet these needs and deliver exceptional results. Quality Assurance: We are committed to providing machines of the highest quality. Each Bamboo Board Particle Screening Machine undergoes thorough quality checks and is built with precision to ensure reliable performance and longevity. Dedicated Customer Support: We value our customers and strive to provide excellent customer service. Our knowledgeable support team is readily available to assist you with any inquiries or concerns, ensuring a smooth and hassle-free experience. Competitive Pricing: We offer our Bamboo Board Particle Screening Machine at a competitive price, providing excellent value for your investment. Our goal is to help you optimize your production process without compromising on quality. Ensure clean and high-quality bamboo boards with the Prashant Bamboo Machines Bamboo Board Particle Screening Machine. Contact us today to discover how this reliable and efficient machine can enhance your particle screening process and support your bamboo board manufacturing needs. Description Key Features: Effective Particle Separation: Our Bamboo Board Particle Screening Machine effectively separates particles, dust, and other impurities from the surface of bamboo boards. The machine utilizes a series of screens with different mesh sizes, allowing for precise separation based on particle size. This ensures that only clean and uniform bamboo boards pass through, enhancing their quality and appearance. Customizable Screening Options: The screening machine offers customizable screening options to suit your specific requirements. You can choose from various screen sizes and configurations to achieve the desired level of particle separation. This flexibility enables you to adapt the screening process based on different bamboo board sizes and quality standards. Efficient Screening Process: Our machine optimizes the particle screening process, enhancing your production efficiency. It automates the screening task, reducing manual labor and saving time. The machine’s efficient screening mechanism allows for faster and more accurate particle separation, increasing your overall productivity and ensuring consistent quality control. Versatile Board Sizes: The Bamboo Board Particle Screening Machine is designed to accommodate a range of board sizes. Whether you are working with small, medium, or large bamboo boards, our machine can adjust to handle different dimensions. This versatility allows you to screen bamboo boards of various sizes and meet diverse manufacturing needs. User-Friendly Operation: The machine is designed for user-friendliness, making it easy for operators to use and maintain. The intuitive controls and interface allow for hassle-free operation, while the durable construction ensures reliable performance over time. Our team provides comprehensive training and ongoing support to ensure smooth operation and optimal results. Sturdy Construction: We prioritize durability and longevity in our machine design. The Bamboo Board Particle Screening Machine is built with high-quality materials, ensuring its stability and performance even under heavy usage. It is designed to withstand the demands of a busy production environment.

Sand Screening Machine (VSS-600 and VSS-900)

35,000 - 285,000 Per Piece

1 Piece (MOQ)

We manufacture excellent performing Vibratory San Screening Machine, which is used in building construction for the screening of raw material. The highly durable Vibratory San Screening Machine is appreciated for perfect screening of material, low maintenance cost and user friendly operations. Salient Attributes : Excellent performance Durable Innovative design Cost effective Low maintenance Application Area : Construction industry Technical Specification Description - Sand Screening Machine With 1Hp, single Phase electrical motor Capacity - 5-6 Tons/Hr (3-4 Cu.Mtr/Hr) Vibration - Eccentric vibrator 1440 VPM Loading - Manual Screen Mesh - W 915mm X L 1525mm Dimensions - L 1750mm X W 1250 mm X H 1500 mm Weight - 90 Kg

detergent powder screening machine

75,000 Per Piece

1 Piece (MOQ)

PU Mesh Screen

350 - 500 Per

100 Piece (MOQ)

Features Premium PU Material: Our mesh products are crafted from top-quality polyurethane, chosen for its resilience, wear resistance, and suitability for high-frequency vibrating screens. Versatile Applications: These mesh products are designed for a wide range of industries, including mining, aggregate processing, recycling, and more, where accurate particle separation is essential. Custom Solutions: We offer a variety of mesh sizes, configurations, and fastening options to match the specific requirements of your vibratory screens, ensuring optimal screening performance. Wear Resistance: Our PU mesh is highly resistant to wear and abrasion, ensuring a longer service life and reduced maintenance costs. Efficient Screening: The precision and uniformity of our mesh contribute to efficient and accurate particle separation, improving the quality of your end products. Easy Installation: Installing our PU mesh is straightforward, minimizing downtime during replacement or maintenance. Industries We Serve Our PU mesh products are trusted in diverse industries where efficient particle separation and screening are vital. We serve clients in mining, construction, recycling, and many others. Quality Assurance Quality is at the core of our manufacturing process. Our PU mesh products undergo rigorous quality control measures to ensure they meet industry standards and your expectations. When you choose our products, you choose reliability. Why Choose Us Expertise: With years of experience, we have perfected the art of mesh product manufacturing. Innovation: We stay at the forefront of technology to provide cutting-edge solutions. Customer-Centric: Your satisfaction is our priority. We work closely with you to understand your screening needs and provide customized solutions. Global Reach: We serve customers worldwide, delivering top-quality PU mesh products wherever you need them.