Mixing Settler Unit System

Get Price Quote

Unleash the potential of our Mixing Reactor Pilot Plant, meticulously crafted to enhance your operations and streamline production processes. Representing the culmination of customer feedback and equipment evolution, our mixing reactors offer versatility and efficiency for laboratory, pilot plant, and small-scale production applications. With reduced installation costs and minimized pressure and temperature losses, our systems empower you to achieve scalable and cost-effective solutions. Join us at K-JHIL Scientific and embark on a journey of innovation and excellence.Salient Features : Advanced reactor Systems : Immerse yourself in cutting-edge reactor system designed for precision versatility, and efficiency. Modular Design for Flexibility : Our Pilot plant embraces a modular design, allowing flexibility to adapt to various mixing and reaction processes. Real-time monitoring and control : Experience the power of real-time monitoring and control systems, ensuring accuracy and enabling data-driven decision-making. Highly Customizable Parameters : Tailor the mixing and reaction parameters to your specific requirements, empowering you with unparalleled control over your processes. Applications : Pharmaceuticals Process Development : Conduct pilot-scale studies for pharmaceutical manufacturing, optimizing reaction conditions and ensuring scalability. Polymerization Studies : Explore polymerization processes with precision and control, tailoring polymer properties for specific applications. Chemical Processing : Conduct pilot-scale studies for pharmaceutical manufacturing, optimizing reaction conditions and ensuring scalability. Temperature Controller : Precision control ensured with advanced temperature controller for optimal reaction conditions. Reaction monitoring : Real-time monitoring capabilities enable comprehensive oversight of reactions for enhanced process control. Efficient Heat Transfer : Superior heat transfer efficiency facilitates rapid and uniform heating, promoting consistent and reliable results.

Glass Mixer Settler

Get Price Quote

The MIXER -SETTLER is a revolutionary new device, which makes phase separation automatic and simple, irrespective of the concentration of two phases (interface height). The mixer-settler is the name given to a type of EXTRACTOR made up of a number of mixing and settling chambers connected alternately in series. In the mixing chambers, optimum mass transfer is achieved by through mixing of two phases with the aid of pumps and stirrers. In the simplest case, the MIXER -SETTLER consist of an adjustable overflow valve, stirrer drive assembly and settling zone. The Mixer Settler has a wide application in the Process Industry , Particularly in Azeotropic Distillation Extractive Distillation Steam Distillation Esterification Distillation Stirrer Drive Assembly The mixing chamber consists of a cylindrical glass cover in which a variable speed stirrer drive is fitted. Glass impeller Stirrer creates a negative pressure at the inlet, which can be used to draw liquid from a previous stage in the process. In the mixing zone, a turbine stirrer with variable speed unit mixes the two phases and the mass transfer takes place during dispersion. Separation Zone Separation of phases takes place in two phases. Firstly, The turbulent flow in the mixing zone must be brought under control and converted into axial flow. Then the mixer passes into the separation zone where the two phases separate, due to their specific gravity difference. Auto Continuous Separation The adjustable overflow valve assembly at one end of the vessel can be set for any interface height. The position of the overflow weir is adjusted to suit the relative densities of the two phases. This valve can be operated externally such that the interface height can be set or reset depending on the operating process conditions. The separating head incorporates an internal overflow weir, which is manually adjusted using a hand wheel. Visual Monitoring The transparency of Borosilicate glass facilitates the adjustment of the overflow valve by visual monitoring whereby any change in the process conditions resulting into a change in layer (interface) height can be immediately adjusted by resetting the overflow valve. The resetting of the separation height is very simply achieved by rotating the hand wheel of the overflow valve assembly in the clock or anti-clock direction. Large Interface Plane Area The horizontal glass vessel of the MIXER-SETTLER provides a large interface area of separation two immiscible liquid phases for a given volume. This enhances the efficiency of the separation process. Overview Of The System The system consists of the following adjustable overflow valve, stirrer drive assembly and settling zone.

Best Deals from Mixer Settler

Mixer Settler

Get Price Quote

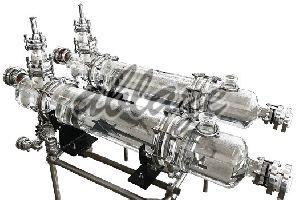

Mixer-Settler Extraction Unit The Mixer-settler system is fabricated and assembled in a compact modular design. The mixer as well as the settler are both integrated together instead of being separate entities. This allows the system to be compact and ideal for laboratory and R&D usage. A single stage of Mixer-Settler consists of a mixing zone and settler decanting zone connected to each other through a Weir zone. A brief description of the zones is as follows : Mixing System The Laboratory mixer consists of a special glass / SS (as per choice) mixing zone, suitable high-speed agitator and a variable speed drive. Besides providing an intimate dispersion the stirrer provides the necessary pumping action. This eliminates the need for external pumps and ensures a large interfacial area for mass transfer. The energy required to produce this dispersion will depend very much on the characteristics of the material and the system used (interfacial tension, viscosity, flow rates, etc). Between the mixing and separation zones, a weir is incorporated to prevent back mixing taking place and maintains the level of liquid in the mixing zone. Besides this, it also acts as a baffle to dampen the flow of liquid into the decanter (settler) for enhancing efficient phase separation. Settling System The settler comprises a horizontal cylindrical pipe which depending upon size may be one or more pipe sections. From the settler, the outlet of the heavy phase, is controlled by an overflow valve. The design of the settler will be influenced by the throughput of both phases and the material physical properties (density difference, viscosity, interfacial tension etc). Multi-Staging Mixer-Settlers Different stages can be connected to each other and the interconnecting pipelines can be done as per your required flow logic. The whole assembly would be controlled through a control panel consisting of suitable circuit breaker MCBs, Relays, digital controllers etc.

Mixer Settler

Get Price Quote

"Mixer-settlers are used for liquid-liquid solvent extraction for purposes such as separation of nuclear chemicals, rare earths and other metallurgical separations. The mixers will have special type of variable speed agitators for transfer of liquids." The company shares glorious credentials with the eminent Manufacturers and Suppliers of Mixer Settler. Preferred For : High speed Excellent strength Efficient working Easy availability Used For : Extraction of liquid-liquid solvent Separating nuclear chemicals Metallurgical separations Rare earths

Mixer Settler

1 - 19,500 Per Piece

1 Piece (MOQ)

FRP Mixer Settler

Get Price Quote

Best known for their dimensional accuracy, compact design, high durability, flawless performance and long lasting life- our FRP Mixer Settler have raging demand in Indian and global markets. Being a trusted Manufacturer, Supplier and Exporter of superior quality FRP Mixer Settlers, our products undergo various quality tests under the supervision of our adroit engineers. Clients can obtain them from us in differing capacities at a reasonable price. Features : Higher rigidity Highly durable Corrosion resistance Low maintenance Specifications : Capacity : 50 - 50000 Liters

Mixer Settler

Get Price Quote

The MIXER -SETTLER is a revolutionary new device, which makes phase separation automatic and simple, irrespective of the concentr two phases (interface height). The mixer settler is the name given to a type of EXTRACTOR made up of a number of mixing and chambers connected alternately in series. In the mixing chambers optimum mass transfer is achieved by through mixing of two phases waid of pumps and stirrers. In the simplest case, the MIXER -SETTLER consist of adjustable overflow valve, stirrer drive assembly and zone.

mixer settlers

Get Price Quote

These are a Class of mineral process equipment used in Extraction Processes. Industrial Mixer- Settlers are commonly used in the Copper, Nickel, Uranium, and cobalt Hydro – Metallurgy Industries where Solvent Extraction Processes or Liquid – Liquid Extraction Processes are applied. Mixer-Settler consists of a first stage that mixes the phases together followed by a non-active settling stage that allows the phases to separate and a gravity separator where the liquids are separately removed as Heavy Phase and Light Phase. For continuous operation, mixing and settling zones are spatially separated from each other. This can be achieved by connecting a series of several such mixing & settling chambers through which the phases are fed in counter – current flow, the system can be designed as per the requirements of a particular problem. The Critical factor in the design of the horizontal mixer- settler is the coalescence ( to come together to form a mass or whole) rate of the dispersed phases. Mixer – Settler Uses: Extraction Process Washing Process Stripping Process Salient Features Uses: Separation of components in solution Chemical Dispersion or Dissolution Cooling or Heating of liquid by direct contact with another Creating Permanent Emulsions

Mixer Settler

Get Price Quote

Mixer settler, We also manufacture the equipments and control systems for sugar industries mainly mill automation, boiler instrumentation, prd stations and embibition water control system.

Glass Mixer Settler

Get Price Quote

Glass Mixer Settler, Glass Pilot Plant, rotary evaporators, Bioreactor

Mixer Settler

Get Price Quote

Mixer Settler, unloading system, Storage Vessels, shaft, Pressure Vessels

mixer settlers

Get Price Quote

mixer settlers, centrifugal exhaust blowers, Industrial Scrubbers, Vessels

Mixer Settler

Get Price Quote

Mixer Settler, Bottle Washing Machine, Slurry Mixer, dry mixer

Multi Stage Mixer Settlers

Get Price Quote

Multi Stage Mixer Settlers are used for liquid-liquid extraction process wherever there is huge demand towards flexibility in plant operations. Frequently changing products, alterations to the number of stages required or wide variation in through put can play decisive factors in this process.

Mixer Settler

Get Price Quote

Mixer Settler, FRP Anodizing Tanks, hdpe Chemical Storage Tank

Mixer Settler

Get Price Quote

Mixer Settler, Mixer Grinder Body Set, mixing valve, Mixer Machine

Mixer Settler

Get Price Quote

Mixer Settler, Sulfur Dioxide Absorber, Sulphuric Acid Plant

Mixer Settler

Get Price Quote

Mixer Settler