Asphalt Drum Mixing Plant

2,000,000 - 3,500,000 Per Piece

1 Piece (MOQ)

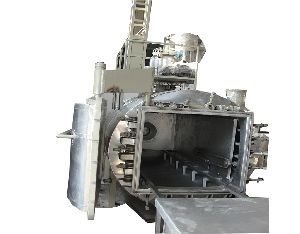

DM-60 Drum Mixing Plant

Get Price Quote

We deliver DM-60 Drum Mixing Plant, which is built with precise engineering and is acclaimed for its sturdy make and long service life. We keep our warehouse clean and installed it with advanced machines due to which the entire lot remains free from different types of damages such as moisture, dust, rain and others. We have ultra-modern packaging systems available to keep the products safe from physical factors that may damage the product to some extent. Thus, we only use qualitative packaging material.

Best Deals from Mixing Plant

Phenyl Mixing Machine

1,999 Per Piece

1 Piece (MOQ)

Mild Steel Tile Adhesive Mixing Plant

150,000 Per Unit

1 Unit (MOQ)

Compact Concrete Batching Mixing Plant

Get Price Quote

1 piece (MOQ)

Ats Series Concrete Batching Twin Shaft Mixing Plant

Get Price Quote

ATS series concrete batching & twin shaft mixing plant is a revolutionary designed model, in which we have used the design concept of very big capacity plants (60-120 cum/Hr). The belt conveying system of era series concrete batching & twin shaft mixing plant saves the time, reduces the maintenance, and increases the output. Incorporated with well-known twin shaft mixing technology, our ATS series concrete batching & twin shaft mixing plant provides optimum along with the belt conveying system. technical features : to1 : plc operated completely automatic control panel to2 : blade mixing technology with planetary gear-boxes to3 : electronic weighing system for better accuracy in design mix to4 : separate weighing system for cement and fly-ash to5 : italian screw feeder, to pour cement speedily to6 : password locking facility to7 : water and ad-mix pour by weight to8 : boom scrapper to make you work easier to9 : pneumatically operated gate for aggregate & sand to10 : italian vibrators to11 : tabulated print our system for each batch to12 : no pit required only nominal civil work to13 : heat proof control cabin to14 : cement with vertical screw feeder (optional) to15 : hydraulic discharge system

Concat RM Series Concrete Mini Mobile Batcing & Mixing Plant

Get Price Quote

CONCAT make RM series of Mini Mobile Batching Machine is widely used on various construction sites as it is the compact batching machine having features like separate weighing of material, auto water dozing system, admix dozing and PLC based printing facility (optional). It comes on 04 pneumatic tyres with tow bar facility which makes it easy to move and shift on site.

ready mixed concrete mixing plants

2,000,000 Per Bag

Reversible Concrete Mixing Plant

Get Price Quote

With the aid of our sophisticated packaging system, our skilled personnel are able to meet the standard as well as customized packaging requirements of the clients. Moreover, we check the entire lot before dispatch. Rest assured for the safety of the products as we have the best facilities at our end. In addition, we have appointed a responsible staff to keep a vigil eye over the same.

Soft Drink Mixing Tank

750,000 Per Set

Epoxy Mixing Cum Casting Plant

90,000 Per Piece

1 Piece (MOQ)

Epoxy Mixing Cum Casting Plant

Get Price Quote

Overview Resin casting is a method of casting where a mould is filled with a liquid synthetic resin, which then hardens. The synthetic resin for such processes is a monomer for making a thermosetting polymer. During the setting process, the liquid monomer polymerizes into the polymer, thereby hardening into a solid. Our resin casting plant is manufactured using quality components and spare parts to ensure optimum performance and long functional life. Resin casting plant is integrated with mixing chamber, which is designed with heating system with temperature controlling arrangement. The simplest method is gravity casting where the resin is poured into the mold and pulled down into all the parts by gravity inside a vacuum chamber. The casting is done in a vacuum chamber to extract the air which avoids formation of air bubbles. The mixing chamber with circular cone-shaped bottom is heated with an oil jacket, the temperature being measured and controlled continuously. The temperature of the wall is hence uniform. A stirrer with baffle rotating at the correct speed which gives shearing action causes thorough resin filler mixing. The agitation exposes all the mix to vacuum& thus degassing is thorough. The mixing paddle drive is with 3 phase motor & reduction gear. The shaft seal is robust rotary seal with tapered roller bearings. The pouring valve is made of P.T.F.E. (Teflon) & this makes cleaning easy. Trap is used to very effective stop abrasive filler particles from entering & ruining the vacuum pump. Features : Mixing chamber for mixing of resin, with hardener, accelerators, pigment and filters, of capacities from 5kg to 1000kg, designed for high vacuum degassing. It is designed with heating system having precise temperature controlling arrangement for controlling the exotherm during mixing, as required. Casting chamber, adequately sized to accommodate desired number of moulds, designed for pouring resin under high vacuum. Pouring system designed for vacuum casting with easy control and observation from outside, with specially designed PTFE valves. The plants can be offered continuous production process. Applications : CT and PT manufacturer Dry type transformer etc

Drum Mixing Plant

Get Price Quote

Phorate Granule Mixing Plant

Get Price Quote

As, our products are manufactured following guidelines set by international quality managements systems, they are of unmatched standards. With the advancement of technology, we have also adopted a secure payment procedure that is easy to use and featured with multiple options. Features: Cap. 500 kg to 3 ton per batch Long functional life Rigid design High operational fluency

Static Concrete Batching Mixing Plant with Pan Type Mixer (GEPL RMC -30)

Get Price Quote

Known for its optimum performance and high efficiency, our Static Concrete Batching Mixing Plant with Pan Type Mixer is available in GEPL RMC 30 model. Designed to maximum performance and cut costs at the same time, our Static Concrete Batching Mixing Plant with Pan Type Mixer (GEPL RMC -30) provides itself with consistent support to get the best mixed concrete possible. Tested against the most stringent of regulations, and compared against international standards, our product comes out on top and is guaranteed to be the best choice.

Modular Concrete Mixing Plant

4,700,000 Per unit

Asphalt Batch Mixing plant

Get Price Quote

We Offer Asphalt Batch Mixing Plant that is Designed to Give High Performance and Caters to the Requirements of Construction Industry. We Offer Different Models of Asphalt Batch Mixing Plant with Varied Capacities to Meet the Demands of the Clients. Today, We are Listed as One of the Prime Manufacturers and Exporters of Asphalt Batch Mix Plant. asphalt Batch Mix Plantâ consists Ofcold Aggregates Bin Feederdryer Drumburnerbag House Filter Unithot Aggregates Bucket Elevatorfour Deck Vibrating Screenhot Aggregate Binpug Mill Type Mixer Unitpneumatic Control Systemfiller Feeding Systembitumen Tankfuel Storage Tankforeign Filler Silocomputerized Control Cabin â salient Featureslow Maintenance Costlow Power Consumptionbetter Spares Availabilityhigh Performance

Continuous Asphalt Mixing Plant

Get Price Quote

The appropriate response is that there is no perfect choice. For each and every site and for each and every occupation necessity there is an alternate arrangement. Thus the decision relies upon cautious examination of all the ‘periphery components’ and the kind of yield that must be created.

Conveyor IN LINE BATCHING MIXING PLANT

Get Price Quote

Conveyor In Line Batching Mixing plant is Known for its efficiency due to Continuous feeding of material in Mixing Unit. Material Feeder is placed Directly on Conveyor Belt where batching is done for Sand and Aggregates and then directly poured in Mixing Unit. Cement, water & ad-mix are weighed individually in separate hoppers. Highly Accurate & Efficient Plant.