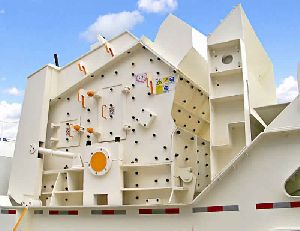

Mobile Impact Crusher

125,000 Per Piece

1 Piece (MOQ)

portable crusher

Get Price Quote

1 Piece (MOQ)

Best Deals from Mobile Impact Crusher

Mobile Impact Crusher

Get Price Quote

Putting crushing and screening process on wheels really boosts process efficiency. Mobile impact crusher offers maximum set-up flexibility, from course to fine crushing, and is cost efficient. It improves working safety, reduces the need for quarry road maintenance, and gives better access to material resources. A further benefit is that waste material can be separated on-site.

Mobile Impact Crusher

Get Price Quote

Putting crushing and screening process on wheels really boosts process efficiency. Mobile impact crusher offers maximum set-up flexibility, from course to fine crushing, and is cost efficient. It improves working safety, reduces the need for quarry road maintenance, and gives better access to material resources. A further benefit is that waste material can be separated on-site. Pretreatment: Using the hydraulic hammer to crush the big stone into smaller one, and arrange the worker to cut through the long reinforcement to prevent damaging the belt conveyor. It is easy to adjust the crushing gap, enable to control grain-size and keep good particle shape. Complete crushing function, high productivity, mechanical wear and high comprehensive benefit. Easy to adapt and flexible to collocate with other machines Reliable performance and convenient maintenance

Mobile Impact Crusher

Get Price Quote

Putting crushing and screening process on wheels really boosts process efficiency. Mobile impact crusher offers maximum set-up flexibility, from course to fine crushing, and is cost efficient. It improves working safety, reduces the need for quarry road maintenance, and gives better access to material resources. A further benefit is that waste material can be separated on-site. Features It is easy to adjust the crushing gap, enable to control grain-size and keep good particle shape. Complete crushing function, high productivity, mechanical wear and high comprehensive benefit. Easy to adapt and flexible to collocate with other machines Reliable performance and convenient maintenance Application Mobile impact crusher is mostly used for medium and fine crushing process in stone crusher plant. It well fits for crushing numerous medium and soft materials, such as limestone, feldspar, calcite, talc, barite, clay, tombar thite, kaolin, gypsum, graphite, etc.

Mobile Impact Crusher

Get Price Quote

Putting crushing and screening process on wheels really boosts process efficiency. Mobile impact crusher offers maximum set-up flexibility, from course to fine crushing, and is cost efficient. It improves working safety, reduces the need for quarry road maintenance, and gives better access to material resources. A further benefit is that waste material can be separated on-site. Features It is easy to adjust the crushing gap, enable to control grain-size and keep good particle shape. Complete crushing function, high productivity, mechanical wear and high comprehensive benefit. Easy to adapt and flexible to collocate with other machines Reliable performance and convenient maintenance

Impact Crusher Series Mobile Crusher

Get Price Quote

The impact crusher series mobile crusher machine is suitable for construction waste crushing, mobile crushing operations in mining area, also widely used in water and electricity, highway, artificial aggregate, ore crushing and other operations. Advantage High Quality Impact Crusher Reinforced impact crusher double and three cavity impact crushers all can be freely set from coarse crushing to fine crushing in accordance with the different processing requirements. Self-load Belt Conveyor Retractable self-load belt conveyor. High Quality Thick Steel frame Structure High quality thick steel frame structure makes mobile crushing plant run smoothly extending equipment’s service life. Vehicle-mounted Electronic Control Configuration Vehicle-mounted electronic control configuration space-saving easy manipulation. Product introduction Production capacity : 16-400T / H Note: this is only an average value and the specific is subject to the clients’actual equipment configuration in site. Processable Material : Limestone granite marble basalt iron ore river stone shale bluestone coal cobblestone construction waste etc. Range of Application : Mining smelting building material highway railway water conservancy chemical industry and other industries. The impact crusher series mobile crusher machine is suitable for construction waste crushing, mobile crushing operations in mining area, also widely used in water and electricity, highway, artificial aggregate, ore crushing and other operations. It is a new type of rock crushing equipment, which can greatly expand the concept of coarse and fine crushing areas. Its purpose of design idea stands in customers’ position,putting eliminating obstacles about the limitation of crushing space and environmental pollution as the primary solution. Truly provide customers with simple, efficient and cost-effective operation hardware facilities of projects.

QE441 Free Flow Mobile scalper

Get Price Quote

Our QE441 Free Flow is a new addition to our Premium range of scalpers. The Free Flow variant provides you with a versatile and highly efficient mobile solution for difficult to screen materials, without any plugging or blockages often experienced with traditional screens. Features and Benefits: Aggressive Free Flow screen with wide range of adjustable throws and speeds enables the bottom deck to be tailored for numerous applications Easy operation through a unique colour-coded control panel with sequential start stop Operator safety ensured with 2 speed radio tracking and feeder control as standard Massive stockpiling capability through integrated hydraulic conveyors Compatible for 2-way or 3-way split configurationsaggregates, ores, waste, biomass and other waste derived fuels including products with high moisture contents.

Mobile Impact Crusher

Get Price Quote

We are offering mobile impact crusher. Features it is easy to adjust the crushing gap, enable to control grain-size and keep good particle shape. Complete crushing function, high productivity, mechanical wear and high comprehensive benefit. Easy to adapt and flexible to collocate with other machines reliable performance and convenient maintenance

Mobile Impact Crusher

Get Price Quote

Mobile impact crusher is mostly used for medium and fine crushing process in stone crusher plant. It well fits for crushing numerous medium and soft materials, such as limestone, feldspar, calcite, talc, barite, clay, tombar thite, kaolin, gypsum, graphite, etc.

Mobile Impact Crusher

Get Price Quote

Putting crushing and screening process on wheels really boosts process efficiency. Mobile impact crusher offers maximum set-up flexibility, from course to fine crushing, and is cost efficient. It improves working safety, reduces the need for quarry road maintenance, and gives better access to material resources. A further benefit is that waste material can be separated on-site. Putting crushing and screening process on wheels really boosts process efficiency. Mobile impact crusher offers maximum set-up flexibility, from course to fine crushing, and is cost efficient. It improves working safety, reduces the need for quarry road maintenance, and gives better access to material resources. A further benefit is that waste material can be separated on-site. Features It is easy to adjust the crushing gap, enable to control grain-size and keep good particle shape. Complete crushing function, high productivity, mechanical wear and high comprehensive benefit. Easy to adapt and flexible to collocate with other machines Reliable performance and convenient maintenance Application Mobile impact crusher is mostly used for medium and fine crushing process in stone crusher plant. It well fits for crushing numerous medium and soft materials, such as limestone, feldspar, calcite, talc, barite, clay, tombar thite, kaolin, gypsum, graphite, etc.

Mobile Impact Crusher

Get Price Quote

Features It is easy to adjust the crushing gap, enable to control grain-size and keep good particle shape. Complete crushing function, high productivity, mechanical wear and high comprehensive benefit. Easy to adapt and flexible to collocate with other machines Reliable performance and convenient maintenance

Mobile Impact Crusher

Get Price Quote

FEATURES It is easy to adjust the crushing gap, enable to control grain-size and keep good particle shape. Complete crushing function, high productivity, mechanical wear and high comprehensive benefit. Easy to adapt and flexible to collocate with other machines Reliable performance and convenient maintenance

Mobile Impact Crusher

Get Price Quote

Putting crushing and screening process on wheels really boosts process efficiency. Mobile impact crusher offers maximum set-up flexibility, from course to fine crushing, and is cost efficient. It improves working safety, reduces the need for quarry road maintenance, and gives better access to material resources.

Mobile Impact Crusher

Get Price Quote

1. It adopts ship form steel structure and low vehicle chassis with light weight. The volume is controlled reasonably. Hidden style traction frame is easy to be packed up and put up. The transportation turning radius is very small.2. Feeding guard is lifted by hydraulic pressure, easy to be loaded and unloaded, conveniently and reliably to be fixed.3. Feeding guard adopts hierarchical type with two layers structure which provides prerequisites for widening.4. The vehicle control cabinet is equipped with high-tech LCD touch screen and PLC control system. LCD touch screen with man-machine dialogue function makes it possess the functions of key start, misuse tips and protection, electrical control operations, fault and safe tips. It is convenient, efficient and secure.5. Grizzly bars of the feeder is capable to separate out the small-sized material as the wastes. By adopting the automatic separatory hatch door, materials in the wastes hopper would flow either with the side-opening belt conveyor, or with the main materials.6. Height of belt conveyor is adjustable. It also can be twisted and folded.7. Landing legs adopt hydraulic lift mode which is of convenient operation and reliable performance.8. With overall streamlined body design and metallic paint spraying, this plant is the perfect combination of mechanics and aesthetics. Processed Materials : Iron ore, copper ore, gold ore , manganese ore, limestone, granite, basalt, andesite, quartz, silica, gypsum, volcanic rock, marble, river stone, gravel, coal etc.. Applications : Primary coarse & medium crusher in mining, quarry, mixing and batching plant, road and building construction, highway, railway and subway, and water conservancy. The mobile impact crushers are used for soft to medium-hard natural stone and for the reprocessing of residual construction materials. What is important today, in addition to the quality of the end product, is environmental and cost awareness, availability and a wide field of application. The series of machines unite all these requirements. In the process, they guarantee an end product that represents the high demands of concrete and asphalt granulation standards with regard to grain shape, grain distribution and cleanliness.

Mobile Impact Crusher

Get Price Quote

Putting crushing and screening process on wheels really boosts process efficiency. Mobile impact crusher offers maximum set-up flexibility, from course to fine crushing, and is cost efficient. It improves working safety, reduces the need for quarry road maintenance, and gives better access to material resources. A further benefit is that waste material can be separated on-site. Features Of Mobile Impact Crusher It is easy to adjust the crushing gap, enable to control grain-size and keep good particle shape. Complete crushing function, high productivity, mechanical wear and high comprehensive benefit. Easy to adapt and flexible to collocate with other machines Reliable performance and convenient maintenance Application Of Mobile Impact Crusher Mobile impact crusher is mostly used for medium and fine crushing process in stone crusher plant. It well fits for crushing numerous medium and soft materials, such as limestone, feldspar, calcite, talc, barite, clay, tombar thite, kaolin, gypsum, graphite, etc.

Mobile Impact Crusher

Get Price Quote

Features It is easy to adjust the crushing gap, enable to control grain-size and keep good particle shape. Complete crushing function, high productivity, mechanical wear and high comprehensive benefit. Easy to adapt and flexible to collocate with other machines Reliable performance and convenient maintenance Description Putting crushing and screening process on wheels really boosts process efficiency. Mobile impact crusher offers maximum set-up flexibility, from course to fine crushing, and is cost efficient. It improves working safety, reduces the need for quarry road maintenance, and gives better access to material resources. A further benefit is that waste material can be separated on-site. Application Mobile impact crusher is mostly used for medium and fine crushing process in stone crusher plant. It well fits for crushing numerous medium and soft materials, such as limestone, feldspar, calcite, talc, barite, clay, tombar thite, kaolin, gypsum, graphite, etc.

Mobile Impact Crusher

Get Price Quote

Putting crushing and screening process on wheels really boosts process efficiency. Mobile impact crusher offers maximum set-up flexibility, from course to fine crushing, and is cost efficient. It improves working safety, reduces the need for quarry road maintenance, and gives better access to material resources.

Combined Impact Crusher Series Mobile Crusher

Get Price Quote

Details The combined mobile impact crusher station is an extraordinary economical and practical device which is suitable for medium and small scale stone crushing production line. Advantage High Quality Thick Steel frame StructureHigh quality thick steel frame structure makes mobile crushing plant run smoothly and extends equipment’s service life. Vehicle-mounted Electronic Control Configuration Vehicle-mounted electronic control configuration space-saving easy manipulation. Scalable Regulation Stand The stent body can be easily retractable according to the different ground level to ensure stable operation of the vehicle when running thus prolonging equipment life. Whole Multi Combination Production Line on A Truck A truck can be equipped with a multiple crushing line according to the production requirements. Product introduction Production capacity : 35-140T / H Note: this is only an average value and the specific value is subject to the clients’ actual equipment configuration in site. Processable Material : Limestone granite marble basalt iron ore river stone shale bluestone coal cobblestone construction waste etc.. Range of Application : This type of mobile crusher is widely used in construction waste crushing plant mining mobile crushing and processing suitable for crushing all kinds of ores and rocks above medium hardness . The combined mobile impact crusher station is an extraordinary economical and practical device, which is suitable for medium and small scale stone crushing production line. It has unique advantages of diverse integrated and fully automatic, self-load conveyor screening equipment, and also can be configured as primary, secondary and tertiary crushing line according on the customer’s diverse production requirements and optimize the configuration combinations.

Impact Crusher Series Mobile Crusher

Get Price Quote

The impact crusher series mobile crusher machine is suitable for construction waste crushing, mobile crushing operations in mining area, also widely used in water and electricity, highway, artificial aggregate, ore crushing and other operations. Advantage High Quality Impact Crusher Reinforced impact crusher double and three cavity impact crushers all can be freely set from coarse crushing to fine crushing in accordance with the different processing requirements. Self-load Belt Conveyor Retractable self-load belt conveyor. High Quality Thick Steel frame Structure High quality thick steel frame structure makes mobile crushing plant run smoothly extending equipment’s service life. Vehicle-mounted Electronic Control Configuration Vehicle-mounted electronic control configuration space-saving easy manipulation. Product introduction Production capacity : 16-400T / H Note: this is only an average value and the specific is subject to the clients’actual equipment configuration in site. Processable Material : Limestone granite marble basalt iron ore river stone shale bluestone coal cobblestone construction waste etc. Range of Application : Mining smelting building material highway railway water conservancy chemical industry and other industries. The impact crusher series mobile crusher machine is suitable for construction waste crushing, mobile crushing operations in mining area, also widely used in water and electricity, highway, artificial aggregate, ore crushing and other operations. It is a new type of rock crushing equipment, which can greatly expand the concept of coarse and fine crushing areas. Its purpose of design idea stands in customers’ position,putting eliminating obstacles about the limitation of crushing space and environmental pollution as the primary solution. Truly provide customers with simple, efficient and cost-effective operation hardware facilities of projects.