Automatic Multi Spindle Drilling Machine

Get Price Quote

We ensure that the payment procedures we undertake are completely secured. Cash payments and bank transfers are some of the modes of payment that we accept.We strictly follow the packaging guidelines and we ensure that finest quality packaging material is used as packaging protects the enclosed product from physical, chemical and microbiological invasion. Details Features of the Multi-Spindle Drilling Machine Specially designed for Scaffolding pipes drilling operation. Machine will have the capacity to load 40 NB, 2000mm length pipes, for auto mode and 3000mm in semi auto mode Drilling Pitch will be 120mm Please note that our machine has 14 spindles fixed in particular pitch. They are not adjustable. If any change in, pitch and no of holes to be drilled, is required please specify in your enquiry. For Drill height adjustment-adjustable Sleeves Type Din 6327 with MT-2 Taper will be provided. (Max drill size 17.5 mm with MT2 taper shank) Machine will be equipped with automatic loading of the pipe from loading table to the V-Block for drilling. Machine will have Manual/semi-auto and Automatic Mode Selection in operation. In manual mode, individual functions of the machine can be operated manually during initial machine setup. After machine setup is completed, it can be run in Semi auto or Automatic-mode by selecting Semi auto or Auto Mode Automatic cycle sequence is as below. Positioning of the pipe. Clamping of the pipe. Slide up with rapid movement till the drill point. Coolant ON & Slide up with feed movement to drill the pipe on one side.

Multi Spindle Drilling Machine

220,000 Per Piece

1 Piece (MOQ)

Best Deals from Multi Spindle Machine

Hydraulic Multi Spindle Drilling Machine

5 Per Piece

1 Piece (MOQ)

Multi Spindle Drilling Machines

Get Price Quote

1 Piece (MOQ)

Speciication Used fo rdrilling large(Ø35) hole in exhaust pipes Holes drilled with relation to bend of pipes Capacity Pipe length upto 2.5m Mulipleholes are drilled on a tube at a time. Horizontal as well as vertical drilling in a same operating cycle.

Automatic Multi Spindle Drilling Machine

5 Per Piece

Multispindle Drilling and Tapping Machine (975)

Get Price Quote

We have parted our infrastructure into several units and one of them is warehouse wherein we keep a huge stock for furnishing urgent and quick requirements of the clients. We promise to deliver the orders within the postulated time frame as we are backed by excellent logistics facility.

CNC Multi Spindle Router Machine

700,000 Per Piece

1 Piece (MOQ)

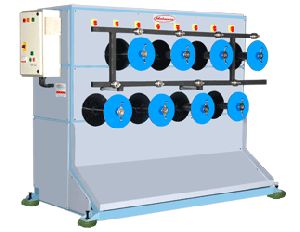

Multi Spindle Hank Winder Machine

32,000 Per piece

1 piece (MOQ)

Multi Spindle Drilling And Tapping Machine

Get Price Quote

Automatic Multi Spindle Drilling Machine

Get Price Quote

We make sure that the packaging of products is done using qualitative material in order to deliver the products safely. Only after complete inspection, we deliver the products in the dedicated time span. We are a noteworthy name and work hard to attain complete client satisfaction. And, for achieving this objective, we facilitate them with easy payment modes. Details : Features of the Multi-Spindle Drilling Machine Specially designed for Scaffolding pipes drilling operation. Machine will have the capacity to load 40 NB, 2000mm length pipes, for auto mode and 3000mm in semi auto mode Drilling Pitch will be 120mm Please note that our machine has 14 spindles fixed in particular pitch. They are not adjustable. If any change in, pitch and no of holes to be drilled, is required please specify in your enquiry. For Drill height adjustment-adjustable Sleeves Type Din 6327 with MT-2 Taper will be provided. (Max drill size 17.5 mm with MT2 taper shank) Machine will be equipped with automatic loading of the pipe from loading table to the V-Block for drilling. Machine will have Manual/semi-auto and Automatic Mode Selection in operation. In manual mode, individual functions of the machine can be operated manually during initial machine setup. After machine setup is completed, it can be run in Semi auto or Automatic-mode by selecting Semi auto or Auto Mode Automatic cycle sequence is as below : Positioning of the pipe. Clamping of the pipe. Slide up with rapid movement till the drill point. Coolant ON & Slide up with feed movement to drill the pipe on one side.

Multi Spindle Drilling Machine

Get Price Quote

Multi Spindle Drilling Machines and Multi Spindle Tapping Machines are used for simultaneous drilling of number of holes in the field of Automobile Industry. According to Customer Component The machines can be designed. This greatly reduces the operation time and also improves the centre distance accuracy. Heads of these Multi Spindle Drilling Machines can be of fixed in center for mass and large batch production. Multi Spindle heads can be of geared construction. We offer these Custom built Multi Spindle Drilling Machines at economical prices. Standard Manufacturing Techniques to be incorporated to get quality machines. Well Experienced Team of Designers, Production Engineers, Service Engineers available to serve customers.

Multi Spindle Machines

Get Price Quote

Multi Spindle machines are built to perform multiple operations simultaneously to offer the best cycle time. Available in horizontal and vertical configurations. Can be provided with rotary or linear indexing. CD tolerance within +/- 0.15 mm for drilling & tapping and +/- 0.03 mm for fine boring and reaming. Can be used for operations such as: drilling, tapping, rough boring & spot facing, fine boring & reaming. Micromation Systems are the leading Manufacturer of Multi Spindle Machine with Hydraulically Operated & four work stations rotary indexing table. It has both Options:- Manually Operated Fully Automatic

Multi Spindle Drilling Machines

Get Price Quote

Over the years, we have become a high-flying name since our Multi Spindle Drilling Machines is qualitative and deliveries are time-bound. With our excellence in this field, we share forefront for supplying world-class array of products from Dera Bassi(India).

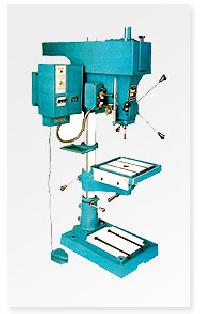

Multi Spindle Drilling Machine

5 Per Piece

Multi Spindle Drilling Machine

Get Price Quote

We are offering premium quality Multi Spindle Drilling Machine, which is widely used for drilling in Railway Track plates and for many other applications. Our Multi Spindle Drilling Machine is widely demanded by auto industries for its accurate operations, durability, easy usage, high performance and low power consumption. This Multi Spindle Drilling Machine is vital in 4 Drilling at same time to 4 identical samples up to Drilling size of Diameter 27mm. Why Our Multi Spindle Drilling Machine? Background of machine is having good made-up base and two rigid vertical fabricated columnsTough guide ways to fixed both the columnsThe Drilling Head's is placed on the guide waysThis machine operates on its fed time as operation starts when both the Drilling Head's are moving down with cutting speedElectrical controller is there with operating pendent Coolants pumpJob fixing fixture is available with locating pin helps in giving accurate location to the work piece and operator timeHigh speedHigh durability

Multi Spindle Bobbin Winders Machine

Get Price Quote

Multi Spindle Knurling / Beading & Perforating Machine

Get Price Quote

- Designed for High Speed Production - Caps are fed to the machine by feeder device and delivered to combination tool set. - Wearing parts such as Knurling and Perforating cutters can be quickly replaced, without the need to disassemble the entire unit - The chuck is controlled by a gear and has a system for simple alignment of knurling

multi spindle drill machine

350,000 Per unit

1 unit (MOQ)

Multi Spindle Drilling Machines

Get Price Quote

Multi Spindle Drilling Machines that we offer are well tested and therefore, are the perfect option on which buyers can easily rely. We are counted among the top Manufacturers and Suppliers of Multi Spindle Drilling Machines. The manufacturing of these machines is done under the supervision of experts. The final dispatch of our Multi Spindle Drilling Machines is done only after the completion of stringent testing procedures.

Multi Spindle Drilling Machine

4,500,000 Per

Automatic Multi Spindle Coil Winding Machine

Get Price Quote

Winding machines are designed for the production of different coils from various application, Machine models varies depending on the size and the Volume requirement from low, medium and high volume segments. Machine are equipped with powerful four axes driven by a Servo Motor with a programmable control system, these machines can wind and wrap automatically with the start and finish terminations. They are more flexible, user friendly, Machines can also be integrated directly, without shuttle, on Coil Production Lines for higher production volumes. These machines can be integrated with other accessories, finishing machines such as soldering and welding, production and assembly lines. Features : 4-axes AC servo Motor transmission system for precise position control and for higher speeds and torques. QCT tooling design 0o 90o 120o wrapping angle design. Equipped with quality tensioner controls for fine winding quality Automated wire assortment, leaving no residual wire. High level language instruction, with 6 touch panel program with user friendly. Password protected program to ensure authorization to operate the machine. Auto load/unload for enhanced productivity Optional : Auto load/unload bar, Turret load / Unload device. Twister, Air cutter, Bifilar winding, Wire break sensor.

Multi Spindle Drilling Machine

Get Price Quote

We are offering multi spindle drilling machine.

Multi Spindle Drilling & Tapping Machines

Get Price Quote

Buckeye offers multi-spindle drilling and tapping machines designed and built to your exact requirements. These machines can be customized to drill and tap holes in any quantity, size or pattern. Carefully engineered and precisely manufactured, Buckeye multi-spindle drilling and tapping machines will deliver the ultimate in high productivity and versatility. The Buckeye Multi-Spindle Drilling Machines perform a variety of drilling, tapping and deep holes drilling plus counter boring, spot facing and chamfering operations. They are rugged, packed with power, precision engineered and are the most productive multi-spindle drilling machines you can buy and the price is right-by design. Price is below any comparable, automatic cycle multi-spindle machine with hydraulic table feed. All of this means savings added to savings. A Buckeye machine is designed to meet the customer's cost per part, part per hour, quality of product and predicted payout requirements year after year. The machine pays for itself. And then it starts to pay for itself all over again.

Multi Spindle Drilling Machines

Get Price Quote

Our high speed Multi Spindle Drilling Machine performs riveting operation on various rivets at a time. Multiple Spindle Drilling Machine offered by us is a blend of performance with accuracy. Robust construction of our Multiple Spindle Drilling Machine assures long lasting performance. We are counted among the key Horizontal Multi-Spindle Drilling Machine Exporters in India. Click Here To View Technical Detail

Multi Spindle Machine

Get Price Quote

We are dealing in multi spindle machine Salient Features : » Compact, low vibration portal frame construction with top mounting cam shaft, resulting in wide open tooling area, easy access to tooling and control cams, unrestricted swarf disposal. » Bar automats AS series are with bar feeding and clamping feature. » Chuck automats ASH series are with manual loading and unloading feature. » Magazine attachment can be fitted to these machines.

Automatic Multi Spindle Drilling Machine

Get Price Quote

By employing qualitative raw material, our entire range is processed. We, as a promising name, procure it from the trusted places only. We make available different payment options to suit the convenience level of the clients. We entertain both online and offline payment processing methods for the convenience of our customers. Features of the Multi-Spindle Drilling Machine : Specially designed for Scaffolding pipes drilling operation. Machine will have the capacity to load 40 NB, 2000mm length pipes, for auto mode and 3000mm in semi auto mode Drilling Pitch will be 120mm Please note that our machine has 14 spindles fixed in particular pitch. They are not adjustable. If any change in, pitch and no of holes to be drilled, is required please specify in your enquiry. For Drill height adjustment-adjustable Sleeves Type Din 6327 with MT-2 Taper will be provided. (Max drill size 17.5 mm with MT2 taper shank) Machine will be equipped with automatic loading of the pipe from loading table to the V-Block for drilling. Machine will have Manual/semi-auto and Automatic Mode Selection in operation. In manual mode, individual functions of the machine can be operated manually during initial machine setup. After machine setup is completed, it can be run in Semi auto or Automatic-mode by selecting Semi auto or Auto Mode Automatic cycle sequence is as below. Positioning of the pipe. Clamping of the pipe. Slide up with rapid movement till the drill point. Coolant ON & Slide up with feed movement to drill the pipe on one side.

Automatic Multi Spindle Drilling Machine

Get Price Quote

We ensure that the payment procedures we undertake are completely secured. Credit cards, purchase cards, PINless debit cards, bank account transfers, cash payments, etc., are some of the modes of payment that we accept. We strictly follow the packaging guidelines and we ensure that finest quality packaging material is used as packaging protects the enclosed product from physical, chemical and microbiological invasion. DETAILS Features of the Multi-Spindle Drilling Machine Specially designed for Scaffolding pipes drilling operation. Machine will have the capacity to load 40 NB, 2000mm length pipes, for auto mode and 3000mm in semi auto mode Drilling Pitch will be 120mm Please note that our machine has 14 spindles fixed in particular pitch. They are not adjustable. If any change in, pitch and no of holes to be drilled, is required please specify in your enquiry. For Drill height adjustment-adjustable Sleeves Type Din 6327 with MT-2 Taper will be provided. (Max drill size 17.5 mm with MT2 taper shank) Machine will be equipped with automatic loading of the pipe from loading table to the V-Block for drilling. Machine will have Manual/semi-auto and Automatic Mode Selection in operation. In manual mode, individual functions of the machine can be operated manually during initial machine setup. After machine setup is completed, it can be run in Semi auto or Automatic-mode by selecting Semi auto or Auto Mode Automatic cycle sequence is as below. Positioning of the pipe. Clamping of the pipe. Slide up with rapid movement till the drill point. Coolant ON & Slide up with feed movement to drill the pipe on one side.

Multi Spindle Drilling Machine

Get Price Quote

Multi Spindle Drilling Machines are generally used for drilling number of holes simultaneous together. They are used in mechanical industry in order to increase the productivity of machining system and to reduce the operation time.

Multi Spindle Head Riveting Machine

Get Price Quote

This multi spindle drilling machines performs riveting operation on more than one rivet at the same time. The number of rivets can be as large as 10 or so. The minimum center distance can be 32 mm ( this depend on size / material of rivet ) and maximum center distance can be approx 120mm. This is a very productive option for large volume requirements. This drilling machines can handle riveting at different levels also ( not in the same plane ).

Multi Spindle Drilling Machine

800,000 Per Machine