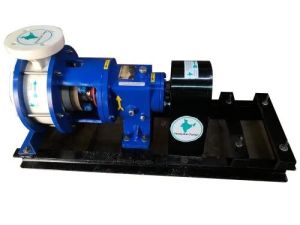

Centrifugal Non Metallic Pumps

Get Price Quote

1 Set(s) (MOQ)

We LEAKLESS (INDIA) ENGINEERING engaged in offering LCP Series Non Metallic Anti-Corrosive Centrifugal Injection Molded Pumps to our clients. The offered range of molded pumps with extra wall thickness and pressurize molding process for free porosity and blow holes are available with semi open impeller, The offered range of molded pumps is designed utilizing high grade raw material and modern techniques in conformation with the highest quality norms and standards MATERIAL OF CONSTRUCTION: ● POLYPROPYLENE (P.P) ● ULTRA HIGH MOLECULAR WEIGHT (UHMW-PE) ● GLASS FILLED POLYPROPYLENE (G.F.P.P) APPLICATIONS AND INDUSTRIES SERVED: ♦ CHEMICAL PROCESSING ♦ EFFLUENT TREATMENT ♦ RECIRCULATION PROCESS ♦ PHOTOGRAPHIC PROCESSING ♦ DRUGS AND PHARMACEUTICALS ♦ FOOD PROCESSING ♦ PERFUMERIS ♦ DETERGENTS AND CAUSTICS ♦ BREWERIES ♦ PETROCHEMICALS ♦ DYES AND PIGMENTS ♦ PAPER AND PULP INDUSTRIES ♦ ELECTROPLATING ♦ ACID PICKLING ♦ FILTERPRESS UNITS ♦ WATER TREATMENT PLANT ♦ FERTILIZER PLANT ♦ THERMAL AND ATOMIC POWER ♦ SCRUBBER UNITS ♦ PICKLING PLANT ♦ UNLOADING OF BARREL AND UNDERGROUND TANKS Operating Range for Non Metallic Anti-Corrosive Centrifugal Injection Molded Pumps: Capacity Up to 300 m3Hr Head Up to 80 Meters Speed 1450 to 2850 RPM Pump Size-DN 19mm To 150mm Temp Up to 85° C

2 Inch Expert Series Non-Metallic Air Operated Diaphragm Pump

225,000 Per Piece

1 Piece (MOQ)

Benefits Efficiency - Simul-Shift valve provides ultra-positive, reliable shift signal Reliability - Our patented Unbalanced air valve ensures no-stall operation Versatility - Broad range in materials of construction for optimum fluid compatibility Environmentally Sound - Bolted construction for leak-free fluid handling and ribless fluid caps to eliminate cracking Serviceability - Easier service through modular design Pump Casing Materials Polypropylene Conductive Polypropylene PVDF (Kynar) Conductive PVDF Diaphragm Materials Long Life PTFE (not available with C-PVDF) Santoprene Hytrel Nitrile Medical Grade Santoprene PTFE w/ Santoprene backer Viton Weight lbs (kg): Polypropylene, Threaded Port 19.35 (8.78) Polypropylene, Center Ported 19.59 (8.89) Polypropylene, Side Ported 19.87 (9.01) PVDF, Threaded Port 25.83 (11.72) PVDF, Center Ported 26.72 (12.12) PVDF, Side Ported 27.15 (12.32) Maximum dry suction lift ft(m): 19 (5.7) Sound Level: 70 PSI60 Cycles/Min79.7 db(A)

Best Deals from Non Metallic Pumps

Centrifugal Non Metallic Pump

11,000 Per Piece

10 Piece(s) (MOQ)

Application:Effluent Treatment, Filter Press For Dyes And Chemical, Water Treatment Plants, Scrubbing Corrosive, Drugs And Pharmaceuticals, Fertilizer Plants, Pickling Plants, Caustic Soda Plants, Recirculation Of Chemicals In Plants, Electroplating, Dyestuffs, Thermal And Atomic Power Plants.

Non-Metallic Centrifugal Pump

Get Price Quote

1 Pieces (MOQ)

Non Metallic Axial Flow Pump

Get Price Quote

We offer Non Metallic (FRP) axial flow pumps with following specifications: It is unmatched in the industry for low head/high capacity pumping requirements especially when highly corrosive or abrasive solutions or slurries are involved. Extended service life, mechanical reliability, custom designs and a wide range of materials allow the model AF to pump practically any liquid * Range of coverage : Material of construction:FRP/Non Metallic Axial Flow Pump.

Non Metallic Centrifugal Pump

12,000 - 70,000 Per Piece

1 Set(s) (MOQ)

We are offering non metallic centrifugal pump. Seal proof make largest range of moulded polypropylene pump excellent for handling corrosive and aggressive chemicals like hcl h2so4 (dil), hno3 naoh etc.

Sealless Magnetic Drive Pumps, Non Metallic Pump, Megnetic Drive Pumps

Get Price Quote

1 Set(s) (MOQ)

We are offering sealless magnetic drive pumps, non metallic pump, megnetic drive pumps. mg series pumps are injection moulded, non metallic, megnetic drive, close coupled, horizontal, single stage, end-suction, centrifugal pump with rotary shaft design to surpass performance expectations in the most demanding chemical applications and enviroment.

non metallic pumps

Get Price Quote

Non Metallic pumps are made up of matreial like Polyropylene, PPH,PVDF,PFA. these are corrosion resistant pumps and mostiy used in chemical industries. Application of Non Metallic Pumps : Dyes & Inermediates industries Effluent Teratment Plants Alkalies & Atomic Power Station Paint industries Hydro & Atomic Power Station Picture Tube Industries Pharamaceutical Plants Steel Re-rolling Plants Acid Regeneration Plants Chemical Industires Temperature Resistance: PP Upto 60`C PVDF Upto 120`C PPH Upto100`C PFA Upto 200`C

MJ / MJ-B Series Standard Non Metallic Magnetic Drive Pumps

Get Price Quote

MJ Series pumps are fluoropolymer lined, magnetic drive, horizontal, single stage, volute casing, center line discharge, end suction, sealless centrifugal pumps with rotary shaft design to surpass performance expectations in the most demanding chemical applications and environments. Dimensional and design criteria of MJ pumps conform to ISO 2858 / ISO 5199 / EN 22858. Sealless, Fluoropolymer Lined, Standard Chemical Resistant Magnetic Drive Pumps Head : upto 50 meters Flow : upto 50 m3/hr Materials: PFA/PVDF/CFRPVDF

Metallic and non metallic teflon lined pumps

10,000 - 200,000 Per Inr

1 Piece (MOQ)

MANUFActurer of centrifugal teflon lined pumps

non metallic pump

Get Price Quote

We are instrumental in offering Non Metallic Pumps. Manufactured with the use of superior quality and sophisticated components, our Non Metallic Pumps are guaranteed for efficient long term usage. These Non Metallic Pumps have high endurance. The properties like corrosion resistance and compact design make our Non Metallic Pumps widely appreciated and demanded. Types Available Non metallic pumpsPortable non metallic pumpsElectric non metallic pumpsMotorized non metallic pumpsPressure non metallic pumpsAlso offer and vertical pumps Features And Benefits All the wetted parts are made from investment castings giving excellent surface finish, sound casting, and better efficiencyMaximum interchangeability therefore minimum spare parts inventory required to be maintainedBack pull out design permits quick inspection, repairs of rotary assembly without disturbing pipe line and motor connectionsHydraulic performance maintained by simple external axial adjustment of impeller wearExclusive balanced thrustStandard dimensions cuts layout costStandard foundations save installation and drawing time, talent and moneyFully open impeller for various fluid transfers ranging from clear to suspended solids Applications Chemical : Caustic transfer, Acid unloading, Monomer and polymer transfer, molten sulphur and urea, Liquid ammonia Liquid Nitrogen.Petrochemical : Aromatics, Low Specific gravity hydrocarbons, gas oilPulp and paper : Digester make up-green and white liquor and black liquor recovery, coating slurries, clay, Titanium dioxide and Alum transferSteel and Mill Industry : Waste acid recovery, scrubber service, pickle, liquor circulationGeneral : Textile, food, pharmaceutical and pollution control, chilled water, condensate return, acid recovery, stack scrubbers, filter feed dm water plant

non metallic magnetic drive centrifugal pumps

Get Price Quote

non metallic magnetic drive centrifugal pumps

Non-Metallic Polypropylene Pumps

Get Price Quote

NON METALIC PUMP ( POLY PROPYLENE PUMP)

Get Price Quote

M.O.C P.P PUMPS P P CENTRIFUGAL PUMPS

Non Metallic Centrifugal Pump

15,000 Per

02 Piece(s) (MOQ)

Standard Duty Non-metallic pumps

Get Price Quote

Standard Duty Non-Metallic Pumps are ideally suited for highly corrosive fluids intermittenton-demand, portable low abrasive fluids and suspended solids. Standard duty non-metallic pumps are constructed in Polypropylene, PVDF and Conductive Acetal with TPE (thermal Plastic elastomers) and PTFE options in diaphragms and check valves.

non metallic pumps

Get Price Quote

The complete pump-rotating element can be withdrawn towards the motor end without disturbing the suction or delivery pipeline, due to back pull out design. The motor remain fixed to base plate. The pump rotating element can easily be dismantled into its component. After reassemble no time consuming Re-Alignment is necessary.

Non Metallic Polypropylene Circulation Pump

17,500 Per Piece

1 Piece (MOQ)

non-metallic pump

Get Price Quote

non metallic pumps

Get Price Quote

The company has been serving nearly 80% of the Indian Steel industry and chemical industries since last two decades. PVDF offers the specific advantages of easy processing in accordance with all the conventional methods used in plastic industry. PVDF offers a high degree of crystallinity to the other process which results in superior thermo-mechanical properties.

Non-metallic Diaphragm Pump

45,000 Per Set

POLYPRO PYLENE NON METALLIC PUMPS

Get Price Quote

POLYPRO PYLENE NON METALLIC PUMPS FOR HANDLING ACIDS AND CHEMICALS CHEM FLO PP Horizontal Centrifugal Pumps These heavy Constructed pumps are Designed with all Moulded parts in contact with the pumping Liquid are Polypropylene Engineered Plastic Materials Reinforced with Cast-Iron Metallic system to handle Corrosive, Abrasive and Aggressive chemicals. Sliding and Adjustable Front Bearing System eliminates Impeller Overhanging to a minimum limit also permits easy Installation of any Popular Mechanical Seal without any Dimensional interference. Self Aligned Bearings make easier Assembly and Maintenance. Pumps are available at a rated Flow to 120 m3/hr and 100 meters Head.

Non Metallic Chemical Process Pump

Get Price Quote

We are occupied in contribution Non Metallic Chemical Process Pump to the clients. The limited reverberation design of these pumps improve their competence and presentation. Furthermore, these pumps are extensively valued for their dependability uncomplicated operation and low continuance. We have Non Metallic Pumps, straight fundamentally rip one piece volute covering intend fixed with partially open impeller solitary entry single stage. Non-Metallic Chemical Process Pumps obtainable by us are robust in structure that ensure high presentation with low continuation. These non metallic chemical process pumps are extensively respected for their dependability, easy operation .the pumps are affected in 20 models with utmost inter irregularity. The pumps are appropriate for flood rate up to 400 m3/hr with head individual 100 mts of liquid column. Advantages Non Metallic Chemical Process Pump:- No mechanical seal filling box required. All the wet parts are in P.P. & Teflon structure with stand deterioration & attrition. No foot valve necessary to lift from unconstructive suction No. leakeges quandary just like gland or mechanical seal Normal continuation Easy Eliegment

Non Metallic Centrifugal Pump

Get Price Quote

1 Piece(s) (MOQ)

We are a leading manufacturer and wholesale supplier of Non Metallic Centrifugal Pump from Mumbai in India. We offer the entire range of superior quality nonmetallic centrifugal pumps, which have a wide application in chemical and food processing industries. These pumps come with a powerful centrifugal motor, which assures performance and endurance. We offer these pumps at competitive market prices.

Pro Metallic and Non Metallic Pumps

Get Price Quote

Features Robust construction with thick walled injection, molded fluid casings and Cast Iron or Aluminum center sections to withstand the toughest industrial applications!! Efficiency – Motor design delivers optimum air efficiency Reliability – ARO’s patented “Unbalanced” air valve ensures no-stall operation Versatility – Multiple porting options for your application needs – Available in Flanged, Threaded, or 3 piece Manifold configurations Environmentally Sound – Bolted construction for leak-free fluid handling Serviceability – Easy access to ball checks and fluid caps for maintenance and repairs

Non Metallic Centrifugal Pump

11,000 Per Piece

Non Metallic Centrifugal Pumps

Get Price Quote

We are offering non-metallic centrifugal pumps. non-metallic centrifugal pumps with closed and open impellers, pfa/fep/pvdf/ppcp molded complete non-metallic chemical process pumps. pumps resist highly corrosive chemicals at higher temperature products such as acids, alkalis, solvents and other corrosive liquid used in the chemical process, petrochemical process, refinery, oil extraction, bulk drug manufacturing, power generation, food processing, effluent treatment, steel plants and similar core industrial uses of non-metallic centrifugal pumps.

Non Metallic Centrifugal Pump

12,000 Per Piece

Prism Metallic & Non Metallic Pumps

Get Price Quote

Parekh Engineering Co. export and supply Prism Metallic & Non Metallic Pumps for various applications such as chemical transfer, effluent treatment plants etc. We offer Polypropylene Pumps (PP Pumps), PVDF Pumps, SS 316 Pumps, Alloy 20 pumps, Cast Steel Pumps, and Cast Iron Pumps to the clients as the range of Prism Metallic & Non Metallic Pumps. These Prism Metallic & Non Metallic Pumps are offered by us at competitive prices. We supply Prism brand Metallic & Non Metallic Process Pumps for your various applications such as Chemical Transfer, Effluent Treatment plants. We are in position to offer Polypropylene Pumps (PP Pumps), PVDF Pumps, SS 316 Pumps, Alloy 20 pumps, Cast Steel Pumps, Cast Iron Pumps for various industrial applications. Range Non Metallic Pumps - Polypropylene Pumps - PP Pumps Metallic Process Pumps - Stainless Steel Pump

Non Metallic Centrifugal Pump

Get Price Quote

Design features : Go to Top PP / PVDF -series pumps are specially design for highly corrosive chemicals in which metal pumps are not recommended or in its cost is higher. The PP- series pumps design are single piece molded polypropylene volute casing with semi-open impeller and casing cover to ensure a smooth running performance against corrosion. The high allumina ceramic sleeve protects shaft to any corrosion and abrasion. The GFT or Sic Vs. Ceramic PTFE below Mechanical seal prevents the leakage from the pumps. The Cast Iron heavy duty oil lubricated bearing housing provide maximum strength to pump. The pumps are also available in Mon-block version with compact design. The PVDF series pump thick walled casing liner & back plate is made of PVDF. A large metal insert in PVDF impeller increased mechanical strength. The PP Series Polypropylene Pumps are also available in monoblock version with compact design. Application For handling highly corrosive acids, alkalis, hydrocarbons, effluent, slurries, and other chemicals like; HCL –33%, Dilute H2so4, Caustic solutions ( NaOH ), HF, H3PO4, HN03, Alum, NaoCl, Feso4, CusO4, FeCl3 etc. The pumps are also used in scrubbing of corrosive gases like Cl2, Br2, F2, I2, So2, So3, Co2 etc. as scrubber pump in various chemical industries, in Pickling process in Steel Rolling Mills, Acid circulation in electro plating industries, decaling in boilers, heat exchangers etc.