Continuous Normalizing Cum Hardening Furnace

2,500,000 Per ONE

normalizing furnace

Get Price Quote

Best Deals from Normalizing Furnace

Normalizing Furnaces

Get Price Quote

We manufacture normalizing furnaces for forgings,casting,metal components,auto components,fasteners,nut bolts and steel components with thyristor control panel.

normalizing furnace

Get Price Quote

Our stern examination in the raw materials and other inputs help us presenting quality assortment of products. With complete inspection on all materials, we ensure premium quality of products. For maximum customer satisfaction, we ensure that the product reaches the customer in the said time slot, owing to our reliable shipping facilities.

normalizing furnace

100,000 Per Piece

1 Piece (MOQ)

Normalizing Furnaces

750,000 Per Piece

Normalizing Furnaces

7,000,000 Per Piece

continuous normalizing furnace

1,150,000 Per unit

normalizing furnace

1,500,000 Per Piece

normalizing furnace

Get Price Quote

Normalizing is the process of raising the temperature to over 60 ° C (108 °F), above line A3 or line ACM fully into the Austenite range. It is held at this temperature to fully convert the structure into Austenite, and then removed form the heating zone and cooled at room temperature under natural convection. This results in a grain structure of fine Pearlite with excess of Ferrite or Cementite. The resulting material is soft; the degree of softness depends on the actual ambient conditions of cooling. This process is considerably cheaper than full annealing since there is not the added cost of controlled cooling. The main difference between full annealing and normalizing is that fully annealed parts are uniform in softness (and machine ability) throughout the entire part; since the entire part is exposed to the controlled furnace cooling. In the case of the normalized part, depending on the part geometry, the cooling is non-uniform resulting in non-uniform material properties across the part. This may not be desirable if further machining is desired, since it makes the machining job somewhat unpredictable. In such a case it is better to do full annealing.

normalizing furnace

Get Price Quote

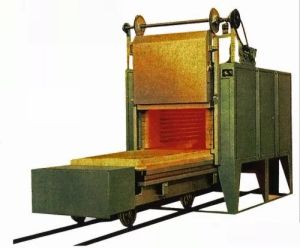

Our standard bogie hearth furnace goes up to 1500°C, however we make custom designed furnaces for any special requirements. High temperature applications are sintering, hardening, annealing and normalizing whereas low temperature applications are tempering and stress relieving. The control system is provided with options to set and control the ramping rate, soaking rate and cooling rate depending on the process cycle, the option of PLC based control is also available. Our Bogie hearth furnace is used in open atmosphere and also in controlled atmosphere as per application. Designs are usually in and out bogie (hearth) movement as well as through and through double door bogie movement is provided for an assembly line or process line. Based on customer requirement, the mode of heating is via electrical heaters, gas fired or oil fired burners.

normalizing furnace

1,890,000 Per Piece

Normal Headroom Hoist

1,025,000 Per

1 Pieces (MOQ)

annealing normalizing furnace

Get Price Quote

annealing normalizing furnace, Precision Machined Parts for Oil & Gas Industry

continuous normalizing furnace

Get Price Quote

continuous normalizing furnace, Continuous Heat Treatment Furnace

normalizing furnace

Get Price Quote

normalizing furnace, Boilers, Heat Exchangers

Normalizing Furnaces

Get Price Quote

Normalizing Furnaces, aluminum furnace, Silicon Carbide Rods

continuous normalizing furnace

Get Price Quote

continuous normalizing furnace, health tablets

batch type normalizing furnace

Get Price Quote

batch type normalizing furnace, batch type sealed quench furnace

Continuous Normalizing Furnaces

Get Price Quote

Continuous Normalizing Furnaces, charging machine, Drop Bottom Quench Furnace