Paint Circulation System

50,000 Per Set

1 Set (MOQ)

Paint Circulation System

Get Price Quote

If you are looking for the best quality Paint Circulation System, avail it from us. It is a closed-loop pipe circuit application where a pump continuously circulates paint. The Paint Circulation System enables better working condition and clear work station. Advantages of Circulating No time lost due to the manual filling of the spray gun feeds, controlling the viscosity or waiting for product delivery Uniformity of the product delivered to each of the work stations (in terms of color, viscosity and temperature) Product savings: total use of the paint Better working conditions: clear work stations Safe environment is ensured by keeping large quantities of product outside the workshop

Best Deals from Oil Circulating System

Oil circulating system

Get Price Quote

O. C. S. (oil circulating system.) which is best suited for paper industry, steel plant, sugar plant... Etc.System are custom built, tailor made, packaged unit skid mounted, ready for installation and piping to parent machine, in simplex as well as duplex arrangements. Fabricated oil tank to hold required quantity of oil with accessories i.e. Mahole, breather cum filler, oil level indicators, level switches for level control, baffles, drain valve, heater etc.Rotary gear, screw or centrifugal type pumps with built in relief valve, connected with electric motor. Filters of basket, self cleaning type, micron rating 10 micron onward depend on application. Material of element S.S wiremesh, paper, felt, fibre etc.

Oil circulating system

Get Price Quote

Oil circulation systems from CENLUB SYSTEMS provide continuous lubrication and cooling to the bearings and gears while they are in operation. This lower operating costs, increase machine life and improve your bottom-line. The oil circulation systems from CENLUB SYSTEMS are self-contained and deliver the required flow of clean lubricating oil at the optimum temperature and pressure to bearings, gear boxes and other rotating industrial equipments. CENLUB SYSTEMS has a wide range of standard systems to choose from. In addition Oil circulation systems can be custom designed to suit your specific requirement. Flow range: 0.5lpm to 3000lpm.

Oil circulating system

Get Price Quote

ApplicationAzad Engg. has developed oil circulating system (O.C.S.) Which is best suited for paper industry, steel plant, sugar plant. etc.ConstrucrionIn O.C.S. we use the gear pump/ screw pump discharge up to 500 LPM driven by electric motor. Pump is connected with reservoir. Reservoir up to 500 LPM driven by electric motor. Pump is connected with reservoir. Reservoir capacity is depend on pump discharge. in line filter, cooler and other control with the gauge filted by standard tubing and fiting on strip.WorkingIn O.C.S. oil is sucked from reservoir with the help of pump and ejected on lubrication point Through filter and cooler, Oil is returned in the reservoir by retuming line. Before pushing the oil again it should be clean with normal temperature.

Oil circulating system

Get Price Quote

Oil Circulatory System (OCS) Lube Oil System (LOS) - In this type of system, the oil is continuously supplied to various moving parts and bearings. The oil not only acts as a lubricant, but also as a coolant by consuming the heat generated in the bearingsmoving parts. The oil after lubrication is returned to the reservoir. These systems are large, employing reservoirs of capacities ranging from a few hundreds of liters to thousands of liters. The pumps are of heavy duty, intended for continuous running, with flow rate ranging from few tens of LPM to few thousands of LPM. These systems are widely used for plants like Cement, Sugar, Paper, Power generation, Steel as well as for heavy duty machineries. Generally, there are a number of points to be lubricated in any of the above mentioned plants. These lubrication points being various gear boxers, bearings, gears, etc. Depending upon the density of these points in a particular area, a common OCS is taken which feeds all these points. The return lines from each of these points are fed back to the reservoir of OCS. The OCS is generally placed in a basement and returning oil runs under the force of gravity by itself. All return lines have a slant towards the OCS so that returning oil doesn't give any back pressure to the oil in the delivery lines. Depending on the complexity of the system and the fund availability, the pressure and flow in each line can be governed through a set of control valves.

Oil Reclaim System

Get Price Quote

This is unique product developed by speedfam in order to have contamination free lapping oil for reuse. It has one abrasive mixture collecting tank in which the used abrasive mixture is poured. The abrasive is separated by baffling & settling process. The clear oil is recepted thru the final chamber from which oil can be taken out for reuse. Viewing windows are provided on the system to varify the level of abrasive settled & necessity of cleaning.

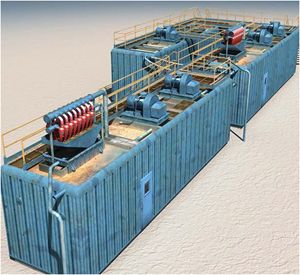

Oil FieldMud Circulating Systems

Get Price Quote

Oil Field System Mud Circulating Systems Unique design concept of Mud Tanks consider two opposing criteria's i.e., for the transport tanks has to be small and light and on the other side they have to be strong and rugged enough to handle mud with a specific gravity of 24PPG. Unique can design and manufacture Mud Tank/Water Tank and Oil Tank according to customers requirement. The quality of Welding seams, surface treatment and special paint is essential features of Unique Tanks. We have designed standard Mud Systems for various sizes of Drill Rigs. We can use material from chosen manufacturers based on our experience so that the quality requirements are always fulfilled.

Oil circulating system

Get Price Quote

Techno Drop has developed different types of oil recirculating systems as per design provided by the customer's This normally contains main oil tank (reservoir), electric motors, pumps, pressure switch, float switch temperature indicator, heat exchanger, pressure gauge, flow switch strainers, duplex filter, drain valve, ball valve, healing elements and electronic control panel.

Oil Conversation Systems

Get Price Quote

Product Range Centrifugal Oil Cleaner Oil Recovery Centrifuge Coolant/Sump Cleaner Oil Mist Extractor Vacuum Dehydration System Magnetic/Paper Band Filter Filter Cart Features No Filter Element No Replacement Cost Improved Product Finish Reduced Oil Consumption Extended Oil Change Period Reduced Machine Downtime Reduced Oil Disposal Cost Applications Wire Drawing | Quenching | Cold Forming | Thread Rolling | Bright Bar Mfg. | Grinding | Honing | Cutting Oil | Hydraulic Oil | Thermic Fluid | Furnace Oil | Engine Oil.

Oil circulating system

Get Price Quote

Dropco has developed different types of oil recirculating systems as per design provided by the customer's This normally contains main oil tank (reservoir), elctric motors, pumps, pressure switch, float switch temperature indicator, heat exchanger, pressure gauge, flow switch strainers, duplex filter, drain valve, ball valve, heating elements and electronic control panel. 5000 cc (5kg),Note - Specification should be provided by customers as per their requirement.

Paint Circulation System

Get Price Quote

We are leading manufacturer and supplier of Paint Circulation System.

Oil Reclaim System

Get Price Quote

This is unique product developed by speedfam in order to have contamination free lapping oil for reuse. It has one abrasive mixture collecting tank in which the used abrasive mixture is poured. The abrasive is separated by baffling & settling process.

Paint Circulation System

Get Price Quote

Paint Circulation System, sealant system, Piggable Paint Systems

Oil Circulating unit system

Get Price Quote

Circulating unit system for grinding wheel head.

Oil circulating systems

Get Price Quote

Oil circulating systems, Heat Exchangers, Filtration Systems, Oil

Paint Circulation System

Get Price Quote

We design, manufacture, install & commission 2-pipe & 3-pipe paint circulation system for automobile paint shop industries.

Oil circulating system

Get Price Quote

We are offering dropco has developed different types of oil recirculating systems as per design provided by the customer's this normally contains main oil tank (reservoir), elctric motors, pumps, pressure switch, float switch temperature indicator, heat exchanger, pressure gauge, flow switch strainers, duplex filter, drain valve, ball valve, heating elements and electronic control panel. 5000 cc (5kg), note - specification should be provided by customers as per their requirement.

Oil Circulating System (O.C.S.)

Get Price Quote

Oil Circulating System (O.C.S.), Nylon Tube, motorized lubrication pumps

Oil circulating system

Get Price Quote

Oil circulating system, Heating Elements