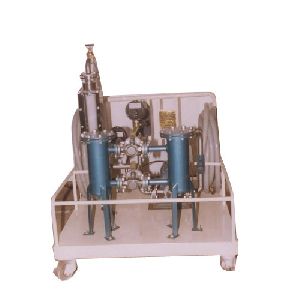

Two Stage High Vacuum X Mer Oil Filtration Plant

Get Price Quote

The company is primarily engaged in the manufacturing and supplying of two stage high vacuum x-mer oil filtration plant all across the country. Reliable performance, cutting-edge technology, and easy installation and working are some of the attributes of our two stage high vacuum x-mer oil filtration plant. The two stage high vacuum x-mer oil filtration plant can be availed from us at the market leading prices.

Lubricant Oil Filtration Plant

Get Price Quote

We have a spacious warehouse that is well designed and properly maintained wherein the entire range is securely stored. Our unit is installed with all required amenities essential for safe storage. Motivated by the aim to deliver nothing short of the best, we have grown as a reliable supplier of Lubricant Oil Filtration Plant in the market.Details : The capacity ranges from 300 LPH onwards The mounting can be done on tyre trolley, roller or skid type as desired.

Best Deals from Oil Filtration Plant

Single Stage Transformer Oil Filtration Plant

Get Price Quote

Single Stage Transformer Oil Filtration Plant that we offer is manufactured under the supervision pf industry experts. Thus, it is the perfect option on which buyers can easily rely. Our Single Stage Degassing Transformer Oil Filtration & Dehydration Plants are suitable for distribution transformers ranging from 100 kVA to 100 MVA. Our Transformer Oil Filtration Plant gives achieve results in the ranges of 70 kV & moisture content in the oil is reduced to 5 – 10 ppm.

Transformer Oil Filtration Plant

Get Price Quote

Electric transformers perform best when the insulating oil is devoid of moisture, dissolved gases and unwanted particles. Even new oils require some treatment to limit these contents to suitable levels. Contaminated oil loses its characteristics of dielectric strengths, resistivity and loss factor. Excessive moisture leads to acid and sludge formation. CEE DEE VACUUM EQUIPMENT PVT LTD designs transformer oil filtration and purification plants that are utilised for dehydration, filtration and degassing of insulating oil. This easy-to-operate and compact equipment has a degassing column with single, two or three stage versions. Known for its precise engineering, these plants are manufactured in different specifications to suit the needs of diverse applications.

Transformer Oil Filtration Plant

Get Price Quote

Transformer oil filtration plant is designed to tame oil problems in the LT distribution transformer sector. The practical experience of transformer oil filter machines used for repairing distribution transformer has led to development of TRANSCURE BS series which is dedicated to handle small oil volumes. Typical capacities are 100 LPH ~ 500 LPH; 1000 LPH~2000 LPH, 2250 LPH & 3000 LPH.

Online Dry out Filtration Machine

392,000 Per Piece

1 Piece(s) (MOQ)

Application of online transformer oil filtration machine: √ĘÄ¬Ę it reduces the chances transformer failure due to moisture online transformer oil dry out is effective measure. Features of the online transformer oil dry out system: √ĘÄ¬Ę the system is permanently installed with a transformer continuously keeps on removing the moisture while transformer is in charged stage. √ĘÄ¬Ę during the filtration process moisture ppm level is continuously monitored. √ĘÄ¬Ę this process does not only remove moisture from transformer oil but also from the insulation as well. √ĘÄ¬Ę the transformer oil is circulated through a series of cylinders filled with specially designed cartridges that absorbs moisture as well as removes solid contaminations from the oil. √ĘÄ¬Ę it will keep on maintaining ppm level which is required for long life and good health of transformers. models available: 1.) todp-000-O 2.) todp-001-O 3.) todp-003-O 4.) todp-006-O

Transformer Oil Filtration Plant

Get Price Quote

Leading Manufacturer and Supplier of Transformer Oil Filtration Plant such as Transformer Oil Filter Machine and Transformer Oil Filtration machine from Pune.   We are assisted by a well-installed unit and a team of skilled personnel who support us in bringing forward an exceptional spectrum of Mobile Transformer Oil Filtration Plant. Accessible with us in a range of provisions, these are developed using top class material along with modern technology. Also, our products are examined sternly prior getting dispatched at the end of our customers. Features:  Less maintenanceReliableRobust construction   With a motive to meet with the changing needs of our customers, we are highly capable of presenting to our clients an extensive spectrum of Transformer Oil Filtration Plant. These are widely recommended and cherished amid our clients owing to their usage in industrial applications. More to this, these are widely examined to maintain its flawlessness. Features: Moisture reduced to less than 6 pap in single passGas content reduced to less than 0.2% by volumeDielectric strength greater than 60KVFilter replacement is easier in less time.Heating by sheathed electric heater with low watt density of heaters.High vacuum pump compact and vibration free.Online PPM measurement (Optional)Simple to operate and require minimum operator attention.

Transformer Oil Filtration Plant

750,000 - 3,000,000 Per set

1 Set (MOQ)

Oil Filtration Plant

65,000 Per Piece

1 Piece (MOQ)

Transformer oil filtration plant manufacturer india

185,000 - 250,000 Per Sets

2 Set (MOQ)

Transformer Oil Filtration Plant

Get Price Quote

Please share Byers details

Transformer Oil Filtration Plant

Get Price Quote

We are providing services as following : on line transformer oil filteration, transformer oil fitleration, filter machine available on rental basis, transformer overhauling at site, transformer repairing, tranformer oil purification, transformer oil filteration solution, transformer oil filteration services, transformer spares in punjab and chandigarh.

TRANSFORMER OIL FILTRATION AND DEHUDRATION/ PURIFICATION PLANT

Get Price Quote

Transformer & Capacitor Manufacture   Skid Mounted Plant For Preparation Of New Oil Prior To Appratus Filling And Impregnation.     Transformer Repairers   Complete Plane For preparation Of New Oil And Regeneration Of Used Oil For Reuse. We Also Provide The Purification System.     Transformer Owners   Movable Plants are available in variety to allow on-side servicing of transformer oil right in the substation or any places.     Points For Selection Of Plants   RANGE OF SIZES OF TRANSFORMERS : Flow rate is decided.   LOCATION OF TRANSFORMERS TO BE FILTERED : Mounting & construction type is decided.   REQUIREMENT OF OIL QUALITY & TIME AVAILABLE FOR FILTRATION & DRYING : Working vacuum is decided.   WORKING VACUUM : Single & two & three stage degassing is decided.     Plants are available in different types of construction   -Open & enclosed models   -Stationery   -Portable & mobile models   -Single & two & three stage dehydration system

Oil Filtration Plant

Get Price Quote

Transformer Oil filtration services are very necessary for any kind of transformer, as it upgrades the functional strength & effectiveness of the transfomer. We as established company in power sector provide or setup the transformer oil filtration plant, which are suitable for various different applications with highest accuracy. Due to our Higly qualified & expert engineers, we have various featured traits whioch are most appropriate to increase the utility factors of transformer. We gained the peak position in providing transformer oil filtartion plant in the market due to our quality driven & innovative services.We offer oil filtration upto 50,000 KVA Transformer. We are having 3000 Leter- Per Hour double Stage Oil Filtration & Dehydration Plants. We are engaged in providing maintenance, repairing & testing services of transforemr ACB, OCB, Panel Boards etc.

Standard Vacuum Transformer Oil Filtration Plant

Get Price Quote

The Standard Vacuum Transformer Oil Filtration Plant offered by us is designed for continuous trouble free operation. Our Standard Vacuum Transformer Oil Filtration Plant shows high performance under extreme climatic conditions also.

Oil Filtration Plant

Get Price Quote

we are providing services as following : On Line Transformer Oil Filteration, Transformer Oil Fitleration, Filter Machine Available On Rental Basis, Transformer Overhauling At Site, Transformer Repairing, Tranformer Oil Purification, Transformer Oil Filteration Solution, Transformer Oil Filteration Services, Transformer Spares The Ultra High Vacuum type Oil Treatment plant is ideal for treating new Transformer Oil and reconditioning of used oil in EHV class transformer, shunt Reactor and other oil filled equipments.The process adopted is quite simple and the modus operating will be by first heating the oil and then passing the same through the specially designed filter and then the oil is Vacuum treated, which in turn, will dehydrate and degasify the oil, to meet to our specification:

mobile transformer oil filtration plant

Get Price Quote

During its operation of generating, transmitting and distributing power transformers give out heat which is absorbed by insulating oils. This oil has a tendency to absorb moisture from windings which leads to gradual deterioration of dielectric strength. Our filtration systems provide economical and efficient methods of purifying this lubricant. The unit consists of:Filter Unit, Indirect system of Oil Heating, Vacuum Dehydration / degasification Unit Condenser and condensate receiver Feed and delivery pump Piping & Valves Control Panel    Components of Plant:The filter unit is a coarse strainer with a wire mesh filter element for retaining solid particles and a powerful magnet for retaining magnetic particles. It has round filter paper discs held under spring compression. Specially designed heaters with low watt density heat the auxiliary heating oil, which in turn heats the transformer oil maintaining a temperature of 70-80 C. The cylindrical external pressure vessel is fitted with various shallow drip trays and a specially designed spray pipe to increase surface area. The vapor from dehydration chamber is condensed in a condensate receiver of welded M. S. construction. There are feed and delivery pump of rotary gear type coupled directly with motors. Water Separator Collect the water produced. A centralized control panel has indicators for all electrical devices.   Imported thermostat Thermometer for measuring temperature Pressure & Vacuum gauges Flow control indicator lectronic Float Control Electrical instruments, voltometers and ammeters Electrical overloads and overload releases for safety of motors.

Oil Filtration Plant

Get Price Quote

Application:-   These filters are generally used for Oil Filtration Plant system.

Transformer Oil Filtration Plant

Get Price Quote

Our oil filtration plants are used to remove impurities from transformer and switchgear oil such as moisture, dirt, air and other gases. This is a `low temperature and high vacuum` principle based equipment as per the International Standards 6034 (1989) and its latest revision. We manufacture plants of variable capacities of 1200 to 25,000 lph which can be customized to special capacities if required by the clients. This plant takes the impure oil into the system through the inlet ball valve and then pumps it through by a positive displacement pump. A filter prior to this removes solid particles up to 1mm size and magnetic particles. After heating the oil up to 60¬įc it passes through the cartridge filters, where particles up to 5 microns are filtered. A specially designed vacuum chamber removes moisture, air and all the gases with the help of vacuum. The oil falls by way of gravity over the media inside forming a thin film of oil, exposing a larger surface area. The dissolved moisture and gases are evacuated and the oil is ready. ¬† Releted Links:¬† Transformer Oil Filtration PlantOil Filtration PlantMobile Transformer Oil Filtration PlantVacuum Impregnation PlantVacuum Drying AutoclaveAir Drying OvenB.D.V Testing KitCartridge FiltersBag FiltersOil Hoses¬†O-Rings¬† High-Vacuum Transformer Oil Filtration and Dehydration Plants Our Oil Filtration Plants are used to remove impurities from transformer and switchgear oil such as moisture, dirt, air and other dissolved gases. This is a `Low Temperature and High Vacuum` principle based equipment as per the International Standards 6034 (1989) and its latest revision. We manufacture plants of variable capacities of 600 to 25000 LPH which can be customized to special capacities if required by the clients. This plant takes the impure oil into the system through the inlet ball valve and then pumps it through by a positive displacement pump. A filter prior to this removes solid particles up to 1mm size and magnetic particles. After heating the oil up to 60¬įC t passes through the cartridge filters, where particles up to 5 microns are filtered. A specially designed vacuum chamber removes moisture, air and all the gases with the help of vacuum. The oil falls by way of gravity over the media inside forming a thin film of oil, exposing a larger surface area. The dissolved moisture and gases are evacuated and the oil is ready. ¬† Transformer Oil Filtration and Dehydration Plants / Purifiers are available for ¬† Transformer and Capacitor Manufacturers ‚Äď Skid mounted plants for preparation of new oils prior to apparatus filling and impregnation. ¬† Transformer Repairers - Complete plants for preparation of new oils and regeneration of used oils for reuse. We can provide the purification system you need as well as vacuum storage tanks and transformer filling and emptying / pumping station. ¬† Transformer Owners - Portable plants are available in a variety of trailer-types and sizes to allow on-site servicing of transformer oil right in the substation. Trailers are available with a wide variety of options including laboratory space, oil-testing equipment. Plants are designed for drying out of the transformer insulation and oil filling and impregnation under vacuum. Hot oil circulation and hot oil spray methods can also be used. ¬† The filtration plant will be designed for high vacuum & low temperature of oil for achieving required results.The plant will be Mobile, to be mounted on your Vehicle or Skid Mounted, with or without enclosure, suitable for outdoor or indoor use.All components will have adequate strength & rigidity to withstand normal conditions of handling & transport. ¬† The plant will consist of the following : ¬† Inlet Pump ¬† A 600 to 25000 LPH capacity positive displacement gear type pump will be provided. The pump will be suitable for vacuum & continuous trouble free operation. A pressure release valve will be provided across the gear pump, to control the accidental pressure rise in the plant. ¬† ¬† Capacity ‚Äď 600 to 25000 LPH ¬† Operating Pressure - 2 Bar ¬† Suction - 4-5 mtrs ¬† By pass arrangement will be provided in between Inlet & Outlet ¬† ¬† Heaters ¬† Nicrome or Kanthal wire heater elements inserted in refractory formers will be provided in protection tubes to avoid localized overheating, hot spot formation & breaking of oil. Heaters will be capable of heating oil from 200 C. to 600 C., as recommended in IS 6034 ‚Äď 1989. Total heater power will be 9 to 248 kW divided into two/three groups. Each group of heaters will be controlled by TIC. An additional thermostat will be provided as a safety to control the temperature during accidental temperature rise.The surface density of the heater pipes will not be more than 2.5 watts/cm2.A drain valve for the heater tank will be provided. ¬† ¬† Indirect type, Wound elements placed in ceramic formers located in Protection Tubes. ¬† Heater Power :¬†9 to 248 KW. ¬† A Pressure Safety Valve & a Drain Valve will be provided. ¬† A Control Thermostat and a Safety Thermostat will be provided. ¬† ¬† Filtration System ¬† Filtration system will consist of the following, ¬† A Preliminary filter ¬† This filter will be provided to prevent any damage to inlet pump by straining magnetic & all other particles above 1mm size. The cleaning of the filter is possible without dismantling the filter from the pipeline. ¬† Cleanable without dismantling ¬† ¬† Flow capacity ‚Äď 600 to 25000 LPH ¬† Rating - 50 mm ¬† Arrests magnetic particles B Pre-Filter ¬† Filters will be easily changeable. It will be suitable for removal of particles larger than 20 microns. It will be suitable for removal of sludge content in the used oil. This will enhance the life of fine filter. C Cartridge Filter (fine filter) ¬† Throw away type, non-hygroscopic cartridge filter elements of one-micron rating will be provided. The cartridges are easy for replacement & have large dust holding capacity. ¬† Cartridge Filter (fine) placed in a steel housing. ¬† ¬† Flow capacity ‚Äď 600 to 25000 LPH ¬† Rating - 1 Micron ¬† ¬† Ionic Reaction Column ¬† An Ionic Reaction Column of 10 to 40 Kg activated alumina will be provided for reduce the acidity in the oil. A bypass arrangement will be provide for after first filling with IRC. ¬† ¬† Degassing Chamber (Single Stage as well as Two Stage) ¬† It will be of M.S. welded construction. The chamber will be designed to withstand the suitable vacuum. In the degassing chamber, dissolved gases & moisture from the oil will be removed. A specially designed media will be provided in the degassing chamber to offer maximum surface area, to form a thin film of oil, to achieve maximum possible removal of dissolved gases & moisture at the rated flow rate. One high level & one low level float switch will be provided to control the oil level in the degassing chamber. ¬† Two stages will be separated by a siphon seal.Highly efficient Two Stage degasser packed with Raschig Rings & equipped with the following : ¬† ¬† Totally Welded ¬† Sight Glass & Lamp Shade ¬† Raschig Ring Trays ¬† Low Level and High Level Float Switches ¬† Level Sensor will provided in Degassing Chamber ¬† ¬† Outlet Pump ¬† A centrifugal pump will be provided at the outlet. The capacity of the pump will be 12000 LPH and it will be suitable for sucking oil from degassing chamber, held under vacuum. ¬† ¬† Capacity - 12000 LPH. ¬† Discharge Head - 8 Mtrs ¬† ¬† Vacuum Pumping System ¬† A combination of roots & rotary vacuum pumps will be provided for evacuation of degassing chamber.¬†An additional connection with an isolation valve will be provided in the system, to facilitate evacuation of transformer tank, simultaneously.The vacuum pumping system will be equipped with all-necessary accessories like Vapour trap, condenser, valves & gauges etc.The specifications of the vacuum pumps will be as follows: ¬† Rotary Oil Sealed Pump Pumping speed (Minimum) Ultimate vacuum Make Indo Vacuum/Dicon/Tuthill/Leybold/Woo Sung/ Shinko Seiki/Reputed ¬† Mechanical Booster (Roots) Pump ¬† Pumping speed (Minimum) Ultimate vacuum Make Indo Vacuum/Dicon/Tuthill/Leybold/Woo Sung/ Shinko Seiki/Reputed ¬† The Vacuum System will be equipped with the following : ¬† ¬† Vacuum Gauge (Bourdon Type), Range: 0 to -760 mm of Hg ¬† Vacuum Gauge (Digital Type), Range: 1 Torr ¬† Airing Valve ¬† Non return Valve ¬† ¬† Cooling System ¬† For cooling, a condenser will be provided in the vacuum line. A condenser will be provided, to maintain ambient temperature of the water which will be circulated through this condenser for collecting water in to the trap. One water tank will be provided in to the top of the mobile van having capacity to hold 100 liter water. ¬† ¬† Non Return Valve ¬† One non return valve will be provided at the inlet and one at the outlet, which will prevent mixing of filtered & unfiltered oil, in case of power failure. ¬† ¬† Valve & Piping ¬† Two airing valves will be provided for airing the vacuum system. All inline valves will be Ball Valve in case of Fully Automatic System then Valves will Solenoid Valves with carbon steel body & S.S. ball, suitable for vacuum application. ¬† ¬† Oil & Vacuum Valves will be of Solenoid type or Ball Valve. ¬† Piping will be of Normal Steel. ¬† Mechanical Non Return Valves before Degassing Column & at Plant outlet ¬† Oil Sampling Valve ¬† Isolation Valve at Plant Inlet & Outlet ¬† One¬†pressure gauge¬†at the inlet of the cartridge filter will be provided. One bourdon type¬†vacuum gauge¬†& one¬†digital gauge¬†(for measurement of fine vacuum) will be provided in the vacuum system.Independent electric drives will be provided for all pumps. Motors will confirm generally to is 325 (testing) & will be of CGL / Hindustan Motors / Siemens or any other reputed make. Starters will be of direct on line type. ¬† ¬† Control Panel ¬† The enclosure will be fabricated out of CRCA sheets & will be suitably coated to protect from weather. All electrical control gears, mains isolating arrangement, starters, contactors, pilot lamps, push buttons, HRC fuses, relays, indicating lamps and interlocking arrangements will be housed in the enclosure. All wiring will be neatly routed & all wire terminations will be suitably identified with ferrules.A tube light will be provided for plant illumination. The plant will be suitable for operation on 415 V, 3 Phase, 50 Hz. A.C. supply.Incoming Power Supply Cable for Control Panel is to be arranged by the Customer and is not included in scope of our supply. ¬† Electrical Interlocks ¬† ¬† The inlet pump will be interlocked with the heaters, in such a way that unless the oil is actually flowing in the system, the heaters cannot be energized. The electrical interlock between heater supply and motor supply will also be provided so that as soon as the inlet motor trip due to some fault in the drive/due to supply failure, the heater supply will also be automatically cut off. ¬† In case of power failures, electro magnetically operated inlet and outlet solenoid valves will be closed and prevent oil from entering the degassing chamber. The moment oil inlet pump or discharge pump is switched on the corresponding valves will open automatically. ¬† The suction pump and the level controller in the degassing chamber will be interlocked in such a way that when the oil/foam level in the degassing chamber increases beyond the desired level, the suction pump will be automatically cut off so that there is no further flow of oil in the degassing chamber. ¬† The temperature indicator of digital type, together with thermostat provided will automatically switch on/off the heater elements in groups so that temperature of the oil during treatment will not be permitted to rise above the pre-set value. ¬† A pre-set safety thermostat provided on the heater vessel will switch off all the heaters in case of any accidental temperature rise of the oil above safe temperature levels so that any likelihood of fire hazard is fully eliminated. ¬† The inlet gear pump will be provided with built in relief valve to take care of accidental pressure increase at the outlet side of the gear pump. ¬† An external relief valve will be provided on the heater vessel to take care of any accidental pressure rise above the safe level in the heater vessel. ¬† ¬† Oil Hoses ¬† Two numbers Nitrile Rubber Hoses each 10 to 15 Meters long with quick connect coupling end connection on both sides shall be provided. One is for inlet & one for outlet. Oil Hoses will be capable of handling the transformer oil at 135oC (max.) and hoses will be will be suitable for full vacuum operating conditions. ¬† ¬† Lifting Hook ¬† Lifting Hooks for Plant will be provided to facilitate ease of Plant Loading and unloading. ¬† ¬† On Line Moisture Meter (As per clients requirement) ¬† A panel mounted Digital Moisture (PPM) Meter will be provided in the outlet line to measure the moisture content in the oil. ¬† ¬† Oil Flow Meter with Totalizer (As per clients requirement) ¬† A panel mounted digital oil flow meter of Vatturkar / Inconel / reputed make will be provided in the outlet line to measure the oil flows. ¬† ¬† Sleeping Arrangement (As per clients requirement) ¬† A frame mounting arrangement for sleeping purpose of the operator will be provided in the mobile van on top of the heater tank. The bed will make from foam sheet and Rexene cover. Cooling fan will be provided in the rest room. Two persons easily sleep in to the rest bed. ¬† ¬† Platform for Bike (As per clients requirement) ¬† The platform will be provided for hanging bike in to the mobile van. The arrangement will be making as per your requirement and it will easy to handle in all situations. ¬† ¬† Painting ¬† A suitable anti rust primer will be applied on the interior and exterior surface of all steel parts, which shall followed by application of two coats of suitable durable paints to serve as base and binder for the finished coat. Under body of carriage will be painted with special black anti rust paint ¬† ¬† Inspection Testing & Commissioning ¬† Inspection & Testing of Transformer Oil Filtration Plant will be carried out by Consignee before dispatch.Commissioning will be done at site; our Engineer will be available on schedule date mutually decided by both parties.Our one person will be provided at your site to train and educate the operators for the period of one month. Site expenditure of the person will be at your scope. ¬† ¬† Drawings & Manuals ¬† One set of Schematic drawings & Guaranteed Technical Particulars of the Transformer Oil Filtration Plant will be provide with the offer and detail drawing with general arrangement of Filtration Plant, Electrical Wiring Diagram and User Manual will be provided at the time of supply. ¬† ¬† Performance Guarantee ¬† We give guarantee for performance of the Plant for a period of 12 months from the date of commissioning of the Plant or 18 months from the date of dispatch, whichever is earlier. During guarantee period we undertake upon written request of the purchaser to repair or replace at our discretion & as soon as possible any parts of goods delivered which can be proved to be damaged or unfit due to bad material, faulty design or poor workmanship. This guarantee does not cover damages resulting out of normal wear & tear, improper maintenance, failure to observe the operating instructions, incorrect operation, excessive loading, the use of unsuitable material, & other reasons beyond our control. This guarantee does not cover Consumables, Rubber Parts (including Oil/Vacuum Hoses) & Electrical Components-Motors. ¬†

turbine oil filtration plant

Get Price Quote

We manufacture Oil filtration plants with varying capacities ranging from500 LPH to 10000 LPH. These plants are available as single stage and double stage variants depending upon the volume of insulating oil o be filtered. If higher capacity plants are required by the clients we can customize our plants to fulfill their requirements. The plants are also designed as mobile units besides the regular stationary unit. For outdoor usage they are supplied with and enclosure. The plant treats the unqualified turbine oil and removes the impurities from it to improve its quality. It efficiently removes water, gas and other impurities especially from emulsified turbine oil.   Features: Automatic systems with automatic advance system for safety, pressure, electricity and temperature constancy with infrared liquid- Has a trapezoidal, spiral, automatic back flushing system. Automatic Unmanned, On-line oil purification with turbine or water turbine Breaks emulsification thoroughly with high- molecule polymeric material Thoroughly clears the liquid water, free water and 80% dissolved water with effective dewatering with one and two step dehydration method Distinctive technique removes impurities by filtering through double FH trapezoidal network and absorbing by high polymer material Has the capacity to equal or surpass 200 and make the cleanness lower grade 6(NAS1638) with its advanced dielectric condensation devices.   This Vacuum Turbine Oil filter uses an advanced detaching theory of membrane which clears water and emulsification to purify the lubricant. The oil emulsifies to a much lesser degree after treatment. This TYA series prevent damage to the lubrication system and extends the life of both the insulating oil and the machinery.