Oil Separators

Get Price Quote

1 Bag(s) (MOQ)

We offer Oil Separators. CAPACITIES MAXIMUM RATED CAPACITY MINIMUM MAXIMUM TEMPERATURES Distillate Viscosity 1.5 - 5.5 cSt40°C (104°F) 4,900 LH 30°F 212°F 4,400 LH Steam Turbine Maximum density of oil 991 kgm3 at 15°C Sludge Holding Space Drive Motor (Direct Drive) Gear Case Oil Control Panels Motor Starter (VFD) Optional Operating Water for Sealing Max chloride content of 60 PPM Water usage per discharge 3,200 LH 1.3 liters 4 KW 4.0 liters 110220 v 240480 v 200-600 kpa 6.0 liters

Alfa Laval LOPX 713 Oil Separator

350,000 Per piece

1 Piece (MOQ)

Best Deals from Oil Separator

Kaeser Air Oil Separator

2,800 Per Piece

10 Piece (MOQ)

High Precision Oil Separator

Get Price Quote

1 Piece (MOQ)

Use of large size oil and air separator, after three separate with high performance and ACE filter makes the oil content low 3 PPM, pressure loss is only 0.02 Mpa, to reduce oil mist discharge, greatly reduce the operating costs of downstream equipment.

Oil Water Separator

Get Price Quote

We are counted amongst the leading Manufacturers, Suppliers, and Exporters of Oil Water Separator. We carry out our operations from Gujarat, India. We use the superior grade of raw materials and updated techniques in manufacturing our Oil Water Separator. The entire range of our separators passes through various quality check, so as to deliver a matchless quality to our clients. Specifications : Most efficient and cost-effective solution to water treatment problems Clean water with no chemicals - 95% of 20 microns / up to 20 ppm oil droplets removed in a single pass. Foot Print: 10% the size and weight of conventional systems. From 2 to 24 m3 = 1 to 1.5 m2 area. Weatherproof MOC closed loop system. Effluent can be recycled for continuous treatment. Low maintenance – Hydro cyclone has no moving parts. Modular add-on features allow customers to achieve higher production efficiencies -cleaner environmental outcomes while meeting government regulations, compact design for reduced footprint and weight, wear resistant materials of construction for increased reliability and low maintenance. Flexible operation for variations in flow rates Manual or fully automated Fixed or portable systems available Can be installed vertically or horizontally Very short residence time (in the order of seconds)-Quicker separation of oil solids reduces many issues like odour, dissolved hydrocarbon process and bacterial fungi generation etc. Highly consistent performance 8 Power supply - only one motor for Pump-Pneumatic version up to 1om3 available Features : Electric and pneumatic options available SS 316 Flameproof and non-flame proof options available Trolley mounted system also available

Square Tramp Oil Separator

Get Price Quote

1 Unit (MOQ)

Air Oil Separators

3,500 Per Piece

1 Piece(s) (MOQ)

Air Oil Separator

2,000 - 20,000 Per Piece

5 Piece (MOQ)

Oil Separator

500,000 - 800,000 Per Set

01 Piece(s) (MOQ)

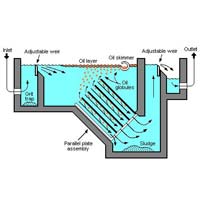

The Coalescing Plate Interceptor employs a series of plate packs inclined at opposite angles in close proximity; the most effective technique for increasing setting area per unit volume. As a result, CPI Separators requires far less space than settling tanks. The units can be offered in fully certified pressure vessels, or atmospheric tanks. Process Technology Waste water enters the inlet nozzle into an enlarged coalescing section. This coalescing section is where heavier solids and sludge settle out of the waste water to the bottom of the vessel where it is discharged through the clean out nozzle. Waste water then flows through the perforated distribution baffle plate. After it is evenly dispersed, it flows down through the plate pack where oil rises to the top of the corrugations and coalesces with other oil droplets. The large oil droplets rise up through the plate pack to the oil/water interface. Coalesced oil will flow over an internally adjustable oil weir and is removed through the oil outlet nozzle. Light solids and sludge separation is simultaneously accomplished within the pack by settling to the bottom of the corrugations where solids are directed to the sludge drain. The flow out of the plate pack travels upward and spills over a fixed water weir, then exits the vessel through the water outlet nozzle for further downstream treatment or disposal. Our CPI Separators effectively remove oil droplets of 50 microns or larger, depending on fluid properties. Applications Oilfield production onshore and offshore Refineries Petrochemical Plants Industrial Plants Rainwater runoff Water treatment facilities

marine Separators

Get Price Quote

Where saving money is crucial, our company can offer fully reconditioned separators. All reconditioned machines are guaranteed for six months of operation. All machines prior to reconditioning are stripped of all components, cleaned, inspected and rebuilt. The horizontal and vertical drives are carefully checked and new parts are fitted if needed. All ball bearings are changed (only SKF or FAG original ball bearings are fitted). All electric motors are exchanged for new units regardless of their condition. All parts for operating water and inlet and outlet are checked and replaced if needed . All 'O' rings and gaskets are automatically replaced with new ones. Spindle heights, operating water paring disc and oil discharge paring disc heights are brought into line with the original manufacturer�s specifications. The bowls are dismantled and checked for wear and damage on all sealing faces. Lock rings large and small are checked for wear and zeroed in the correct position. Bowl discs are mechanically polished and are returned to "new" condition. All sealing faces are then machined and bowls are re-balanced to original manufacturers� specifications. Balance Certificates are then issued for each bowl. Finally, machines are run up and test discharged before they are packed ready for dispatch.

Tramp Oil Separator

Get Price Quote

1 Piece (MOQ)

Air Oil Separator

Get Price Quote

10 Piece (MOQ)

Oil Separator

Get Price Quote

The company offers a high-quality range of the Oil Separators, which are based on the working principle of accumulation. The Oil Separator can work under a maximum pressure of 3.1 MPa and the users can ask for varying connection sizes. The company is one of the most reliable destinations among the Exporters and Suppliers of Oil Separator

Oil Separator

Get Price Quote

Air Oil Separators

Get Price Quote

Air Oil Separators

Oil Separator

1,000 - 40,000 Per Piece

1 Piece (MOQ)

Ammonia Oil Separator

Get Price Quote

1 Piece (MOQ)

Oil Separator

Get Price Quote

10 Pieces (MOQ)

Impingement & Centrifugal Wide product Range, 1.5 To 127 Ton nominal R22 Capacity

Air Oil Separators

Get Price Quote

1 Piece (MOQ)

Company offers genuine screw compressor air oil seperators custmized filter cartridges and seperators mnfrs as per drawing or sample in very reasonable price

Oil Water Separators

90,000 - 150,000 Per Piece

1 Piece (MOQ)