Head Box

Get Price Quote

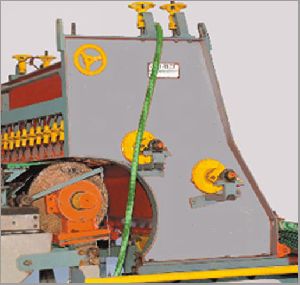

Open Type Head Box Machine Speed Up To 300 Mtr/min. Slice Width Up To 3500 Mm. Construction Complete Is Stainless Steel. Profile Variation Across The Deckle Is Maximum+/-3 % GSM. Cylindrical Tapered & Rectangular Tapered Manifold Can Be Provided. Bottom Lip Machined & Ground For Smooth Flow For Stock. Dryer Section Mild Steel Fabricated Dryer Cylinder From Boiler Quality Plate With High Evaporation Rate. Cast Iron Dryer Indian & Imported Mode Can Also Be Arranged On Customer Requirement, Available In 4 Ft, 5 Ft & 6 Ft Dia. Shell Thickness From 22 Mm To 32 Mm. Operating Pressure Upto 4.5 Kg/cm2. Framings Heavy Duty From Cast Iron & Mild Steel With Stress Relieved Facility. M.G.Cylinder Mild Steel Fabricated M. G. Cylinder From Boiler Quality Up To Dia. 18 Ft. And Face Up To 5 Mtr. Stainless Steel Coating On Surface Facility Is Also Available At Site. Stress Relieving Facility Is Also Available At Site. Surface Machining & Grinding To Achieve Mirror Finished. Soft Calendar Any Calendaring Concept Selected Is Solely Dependent On Paper Grade And Printability Requirement At Printer’s End. Super Calendaring And Other Classical Calendar Methods Being Too Cumbersome To Operate As Well As To Maintain, Soft Calendaring As Such Has Replaced Super Calendaring In Major Part Of The World. With Its Heated And Elastic Rolls Soft Calendars Present An Economic Alternative. The Uniform Thermal Compression Of The Paper Surface Evens Out The Difference In Compression Within The Sheet. . Pulping Section L.C. Pulpers & Hicon Pulper With Poir Discharge Equipments. Floatation Cells For Deinking Systems. Screening System For Low & High Density Stock- Johnson Screen, B2 Thickner, 3F-Screen, Turbo Separator, Pressure Screens Cleaning Equipments. High Density Cleaners/Low Density Cleaners- Centri Cleaners. Chest Agitator. Separ Plast It Is Formed By A Cylinder Carrying Hardened Tip Blades, Rotating At High Peripheral Speed Inside A Perforated Basket, Accomodated Into A Housing Supplied With Inspection And Out-let Doors. Rejects Are Usually Conveyed To A Vibrating Screen To Separate Them From The Water. Operating Consistency 3.5 To 5 % Screen Hole Size 3.5 To 6 Mm. Depending On The Grade Of Furnish And On The Cleanliness Requirements. Turbo Separator Effective Separation Of Heavy And Light Impurities. Minimum Fiber Loss. With Operating Consistency Of 3.4 %. The Accept Stock Passes Through The Screen Fitted Behind The Rotor. A Force Vortex Is Formed In The Separator By The Stainless Steel, Rotor. The Heavy Particles Are Carried Outward By Centrifugal Force Into The Junk Trap. The Rotor & Screen Are Designed To Slush Paper Chips And Remove All The Non Fibrous Material Which Goes Out As Light Reject And Further Treated In Secondary Separator Of Johnson Screen. Twin Drum Thickner Twin Drum Press Is Basically A Thickner Used For Dehydration Of Stock Prior To Hot Disperser/Kneader. The Maximum The Dehydrated Stock, The Better The Dispersing / Kneading.

Head Box

Get Price Quote

The Head Box consists of MS fabricated rectangular box with tapered tail end at the back side with Necessary stiffners. The front side is provided with SS Spring steel top and bottom slice lips for pulp flow. The total slice lip gap is adjusted by means of two worm gear box units connected to a common hand wheel. For individual micro profile corrections a number of stud and fly nut arrangement is provided along the top lip. A partition plate which can be moved upwards or downwards by means of a screw and wheel arrangements is provided for maintaining the level of pulp in the head box. A SS 304 shower is provided from the top for foam killing. At the bottom portion of the tail end a SS evener roll is fitted which is deiven by a chain and sprocket arrangement by means of a geared motor for avoiding slime formation and maintaining uniform distribution of flow. At the bottom cover of the tapered tailed end equal distance nozzles are provided for pulp inflow. These Nozzles are connected to the nozzles of a tapered SS manifold through flexible hose pipe. The whole head box is cladded inside with SS 304 sheet to avoid corrosion and slime formation. A platform is mounted at the front of head box for easy operating of slice. Features : Uniform cross direction basis weight profile and hydra dynamically balanced. Maintain good deflocculation or fiber dispersion. Good sheet formation and stability of flow. Minimum Maintenance Grade Flexibility Micro spindles at regular pitch for adjustment of top slice. Grounds finish Top and Bottom Slice lips.

Best Deals from Paper Machine Headbox

Paper Machine Headbox

Get Price Quote

Paper Machine Headbox

Get Price Quote

Paper Machine Head Box

Get Price Quote

Headbox is a heart of PAPER MACHINE. This Paper Machine Headbox system is advanced from open Wooden Headbox. Our Paper Machine Head Box is available with crude inlet channels and modern stainless steel flow devices. The Paper Machine Head Box system has seen much development in the last ten years. The special attention is taken by our engineers to make it easy to use. Main Desirable Requirements of a Paper Machine Head Box Uniform Cross-Direction (CD) and Machine-Direction (MD) Basis Weight Profile Good Look Through of Sheet Maintain deflocculating or fiber depression Stability of Flow Minimum Maintenance Grade Flexibility Adaptability for Automation Ease of Operation and easy access for cleaning Range Stainless steel headboxes Rectifier rolls headbox Hydraulic headboxs Turbulent flow way headbox Types of Headboxes We Provide With our specialized designing concept, advanced production process, rich application experience and perfect services, we provide various kinds of etc. We also provide Equipment Installment, Operation Instruction and various Consultation Services for our esteem customers.

Paper Machine Head Box

600,000 Per Piece

Hydraulic Paper Machine Headbox

Get Price Quote

Head Box

Get Price Quote

Open type head box made out of the S.S. 304 plate suitable for low and medium speed paper machine up to 350 m/min.Tapered flow header for uniform velocity conditions.Uniform cross direction basic weight profile.Two holly rolls maintain defloculation or fiber dispersion.Easy accessibility of inside area for cleaning & easy of operation.Stability of flow.Minimum Maintenance.Foam killing shower also provided.

Paper Machine Head Box

Get Price Quote

We are well known manufacturer and exporter of paper machine head box. Price. Salient features: open head box for machine speed up to 350 meters minute. Slice width up to 3800 mm are regularly manufactured. Profile variation across the deckle in maximum ±3 gsm

Head Box

Get Price Quote

We are offering head box for paper machine" hydrolic pressuraised step deffusored head box from 1600 to 5000mm.

Head Box

Get Price Quote

SPECIFICATION Open Head Box for Machine speed up to 350 meters / minute Slice width up to 3800 mm are regularly manufactured Profile variation across the deckle in maximum +-3 GSM Cylindrical Tapered and Rectangular Tapered with Polypick diffuser, Manifold are provided depending upon the quality and production capacity Two numbers Properly designed Evener rolls for evening effect and bette deflocculation Machined and Ground Top and Bottom Lip for smooth flow of stock.

Headbox

Get Price Quote

We offer Headbox. It is an open-type Headbox. The material of construction can be M.S or SS304 or SS316 as per customer's requirements. The width size ranges from 1200mm to 3500 mm. It can be used for different grades of paper.

Head Box

Get Price Quote

* Tapered flow header for uniform velocity conditions. * Uniform cross direction basic weight profile. * Two holly rolls maintain defloculation or fiber dispersion. * Easy accessibility of inside area for cleaning & easy of operation. * Stability of flow. * Minimum Maintenance. * Foam killing shower also provided.

Paper Machine Headbox

150,000 Per Piece

1 Piece (MOQ)

Headbox

Get Price Quote

Paper Machine Headbox

Get Price Quote

Paper Machine Headbox, toilet paper machines, Paper Napkin Machine

Paper Machine Headbox

Get Price Quote

We are offering paper machine headbox. We have gained immense recognition by offering a quality assured range of paper machine head box. This head box is designed and manufactured using high grade raw material with the help of advanced machine and technology by our experts at our advanced manufacturing facility.

Head Box

Get Price Quote

we offer head box scan designs, manufactures and supplies head box of various types as per the specific requirements for different customers. hydraulic head box air cushioned head box open head box

Paper Machine Head Box

Get Price Quote

Specifications Open head box made complete stainless steel. Suitable for machine speed up to 300 mts. Two number holy rolls for uniform mixing of stock. Maximum pulping variation across the width.

Paper Machine Headbox

Get Price Quote

Paper Machine Headbox, Paper Napkin Machine, Paper Slitting Machine