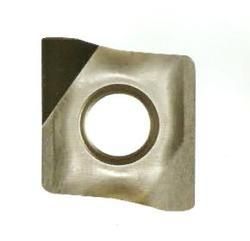

CBN PCD Threading Insert

Get Price Quote

With complete help and support of our team members, we deliver high grade and excellent range that commensurate to globally accepted standards. Owing to our flawless transit system, we are capable of delivering the orders within the promised time frame.

PCD Turning Inserts

Get Price Quote

Best Deals from PCD Inserts

Pcd Inserts

1,500 Per Piece

100 Piece Piece(s) (MOQ)

Indexable Insert With Coating Bk7615:- Increase in process reliability Reducing the processing time by increasing the average Increase in contact time of up to 100% possible

pcd insert

850 - 3,800 Per Nos

1 Piece (MOQ)

We Provide best quality PCD INSERT, PCD Reamers. Turning Milling Threading Grooving

TCMT and TNMA Inserts

1,000 - 1,500 Per Piece

10 Piece(s) (MOQ)

""All radius & dimensions mentioned above are standard, any other radius or customer drawings can also be made as per order"

Pcd Inserts

Get Price Quote

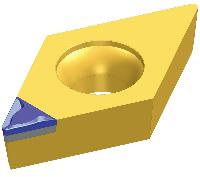

PCD AND CBN INSERTS

Get Price Quote

Our range of PCD inserts are used for machining non-ferrous metals like aluminium, magnesium, aluminium alloy, Ti, silicon and non-metal materials such as glass fiber, ceramics, reinforced plastic etc. Moreover, our tools are also used for planing, shaping, slotting, broaching or gear cutting processes. We offer a wide range of CBN inserts, which are available in different grades and offered at industry leading price. These are used for machining and cutting hard materials, sintered metals, super alloys, hardened steel, and cast iron. Further, the use of CBN inserts provides significant improvement in productivity and economy utilizing high speed machining and hard machining.

Pcd Inserts

Get Price Quote

Pcd Inserts

Get Price Quote

We offers a complete range of high quality Polycrystalline diamond ( PCD ) Inserts for machining nonferrous materials. These Inserts are designed to provide significantly increased tool life, consistent surface finish and dimensional control. As a direct result, over all cost of the component can be significantly decreased, resulting in higher productivity as well as cost savings in the total manufacturing operation are successfully achieved

Pcd Inserts

Get Price Quote

We formulate our Secomax™ PCD grades to significantly reduce production costs when machining aluminum alloys, titanium and other non-ferrous materials. PCD (polycrystalline cubic diamond) is an advanced material that comes as a result of sintering together selected diamond particles at high pressure and temperature.

pcd insert

950 Per Piece

PCD & CBN INSERTS FOR TURNING, BORING AND MILLING

Get Price Quote

PCD & CBN INSERTS FOR TURNING, BORING AND MILLING Superabrasive Materials There are many different types of tip available in the market designed to cope with an array of workpiece materials but for simplicity these may be grouped as follows Polycrystalline Diamond (PCD). Cubic Boron Nitride (CBN). PCD PCD may be used for both roughing and finishing work, although it is usually most beneficial when tight tolerances or high surface finishes are required combined with the need for exceptionally long tool life. It is available in three grades of increasing crystal size and toughness but with an attendant decrease of edge quality. The finest grade is, therefore, only employed where superior surface finish is the main objective, the middle grade is the general purpose material giving long life with good component finishes; the coarse grade is used where maximum abrasive resistance is required and where finish is not critical. We will be pleased to offer advice on the selection of the best grade of PCD and cutting geometry for your particular application CBN If polycrystalline diamond has a major disadvantage, it is that being carbon based, it has an affinity to the free carbon found in most ferrous materials and is therefore generally unsuitable for machining steels and iron based materials. For this reason a range of products has been developed based on polycrystalline cubic boron nitride which have been demonstrated to be extremely cost effective especially with the harder ferrous materials (45-65 HR). Examples of materials that may be considered for machining with these inserts are listed below. Hardened Steels Chill Cast Iron Hardened Bearing and Tool Steels Stainless Steels Hard Facing Alloys which are Cobalt, Nickel and Iron based Grey Cast Iron CBN for Rough Machining: Different types of PCBN exist for the rough machining of the materials listed above which are usually selected on the basis of the required amount of stock removal. For roughing cuts in excess of 1mm depth the PCBN is usually supplied in the form of solid ISO tips for use in a clamp type tool holder, designed for use with negative top rake geometry. It is also usual to provide a strengthened cutting edge by means of a lapped or honed 'T' land. Where roughing cuts up to 1mm only are to be taken or when the applications require positive tool geometry, a brazable type of PCBN may be employed. In these cases the inserts are fabricated in a similar manner to diamond tips but usually with a polished 'T' land. CBN for Finishing: A specific form of CBN with reduced CBN content is supplied for use on fine finishing of hard ferrous materials. This material is capable, given the correct machining parameters, of producing turned finishes equal to those of ground components. The attendant cost savings found from switching from grinding to turning are often very dramatic. Again, the inserts are fabricated in a similar manner to those in PCD. Insert Shape: We follow the normal ISO convention for describing insert shape and geometry, for example an 12mm triangle may be designated as follows T P G B 12 02 02 T = Shape (triangular) P = Insert clearance angle (11°) G = Tolerance class (G) B= Type of insert, i.e., Hole and Chipbreakers 12 = Edge length (12mm) 02 = Insert thickness (2.38mm) 02 = Radius (0.2mm) CBN INSERTS PCD INSERTS PCD CBN MILLING INSERTS When ordering please specify PCD or CBNWe will be pleased to offer advice on the selection of the best grade of PCD and cutting geometry for your particular application.

Pcd Inserts

Get Price Quote

1 Piece(s) (MOQ)

Brand - rudrali hi tech tools type - pcd inserts certification - iso 9001:2015 we have pcdturning inserts, pcd milling inserts, pcd grooving inserts. Types -ccmw 09t304, snew 1204 adfr, tnma 160404, cnma 120404, vcgt 160404, rngn 1204

CBN AND PCD Inserts

Get Price Quote

Sumitomo electric is a renowned name in the field of metal cutting tools in the category of super hard materials they are world leaders. This particular category consist of materials like CBN and PCD which are much higher on hardness scale as compared to conventional materials like carbide or ceramic. Superior mechanical properties make them ideal for machining hardened steel, Hi Speed turning and milling of cast iron, machining exotic materials where heat generation is very high while cutting and similar tough applications where there is conventionally no option but to have grinding or poor tool life ultimately higher cost. Diamond is composed of pure carbon atoms, arranged in a very special crystal orientation that gives it its unique physical properties. The physical properties of the diamond tools, specifically the extreme hardness and wear-resistance, make Motherson PCD tools so unique. CBN & PCD Tools are most ideal for following application areas: Hardened steel machining Hi speed cast iron machining Efficient machining of exotic materials like titanium and nickel base alloys we also provide customized solution as per customer application for varied operations like hardened steel grooving on shafts, small Dia boring in hardened steel, high Speed Milling of Cast Iron components like Cylinder Block, Cylinder head, valve seat machining operations, precision machining of aerospace material like titanium and nickel-based alloy.

pcd insert

Get Price Quote

PCD Milling Insert

Get Price Quote

Pcd Inserts

Get Price Quote

We offer quality PCD Inserts that are used for cutting varied heat treated metals as well as metal workings, which are needed in Automotive industry. We are amongst the reliable Manufacturers, Suppliers and Exporters of the PCD Inserts, based in Chennai (Tamil Nadu). We offer these PCD Inserts at the market leading rates. Used For Cutting : Cast IronAluminumCopperHardened SteelBronze

Pcd Inserts

Get Price Quote

BRAND NAME:SUMITOMO Multi Layer Coating : Long Life Ultra Hard Substrate : Chipping Free Unique Chip Breaking : Chip Control

Pcd Inserts

Get Price Quote

Since the inception of our company, we have been instrumental in offering a wide range of the supreme quality of PCD Inserts to our esteemed customers. These inserts are used for turning, grooving, milling and boring of various metal and non-metal materials. Due to their rich features such as sturdy construction and corrosion resistance, the offered PCD inserts are highly appreciated among our customers. Owing to our extensive transportation facilities, we have been able to deliver these inserts in committed time-period to the customers' premises.

Pcd Inserts

Get Price Quote

Pcd Inserts, pcd shank tools, vitrified wheels, Resin, holders