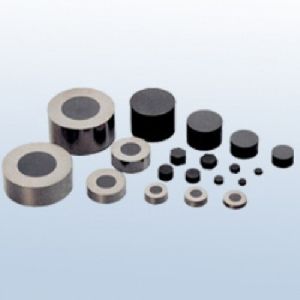

PCD Wire Drawing Dies

1,000 Per Piece

50 Piece (MOQ)

Pcd Dies

2,000 - 3,500 Per Piece

5 Piece (MOQ)

Best Deals from PCD Wire Drawing Dies

Customized TC Wire Drawing Die

Get Price Quote

100 Piece (MOQ)

PCD Wire Drawing Dies

500 - 200,000 Per Piece

1 Piece(s) (MOQ)

PCD Wire Drawing Dies

Get Price Quote

We are a leading name offering the best in class and qualitative array of PCD Wire Drawing Dies. We have a good rapport with the leading names in the industry from whom we source the basic material, required for manufacturing superior grades products. Features : Rust resistant nature Dimensional accuracy High tensile strength

Pcd Dies

Get Price Quote

Backed by an efficient network and trustworthy resources, we have emerged as a dominant supplier of PCD Dies Compression Bakelite Dies in the market. We have faith in transparency in terms of payment whether in advance or full cost. For their convenience, we offer our clients different payment options and make sure these methods are practical.

Copper wire drawing dies

100 - 8,000 Per pieces

20 pieces (MOQ)

PCD Wire Drawing Dies

Get Price Quote

Pcd Dies

4,500 Per Piece

Wire Drawing Pcd die

1,800 - 7,500 Per Piece

5 Piece (MOQ)

PCD Wire Drawing Dies

500 Per Piece

<p>We make available the products using the exceptional quality raw material that is experts certified. This makes our product range completely reliable and genuine. For the convenience of our customers, we issue an invoice stating the entire details such as products, quantities and agreed price. Moreover, we ensure safe and hassle-free payment procedure.</p>

PCD Wire Drawing Dies

Get Price Quote

we are a well-known pcd wire drawing dies manufacturer, exporter and supplier in bangalore, karnataka. our pcd wire drawing dies are appreciated by the clients for their accuracy of the designs and make. these pcd wire drawing dies are made out of best quality metals to make them strong and durable. our pcd wire drawing dies can be obtained at reasonable prices.

PCD Wire Drawing Dies

Get Price Quote

We are offering pcd wire drawing dies. Our company is engaged in manufacturing and exporting high quality range of pcd dies, which is manufactured using premium quality raw material procured from the certified vendors of the market and by the assistance of contemporary technique & machines under the supervision of our skilled professionals. These products find application in various industries. Offered products are appreciated by our esteemed clients for following features giving below.

Pcd Dies

Get Price Quote

PCD Wire Drawing Dies

Get Price Quote

Solid enameling Dies with PCD Insert

Get Price Quote

Product Description Solid Enamelling Dies with PCD insert. We manufacture solid enameling Dies with Diamond insert from 0.200 to 6.00mm. Perfect inner profile allows smooth and continuos flow of enamel on the copper wire and ensures uniform coating. Mikrotek offers standard and customised design in both stainless steel and aluminium bodies.

PCD Wire Drawing Dies

Get Price Quote

Pcd Dies

Get Price Quote

the polycrystalline diamond (pcd) wire drawing dies offered by us are known for their longer die life and excellent wire roundness. These dies have high resistance to wear, cracking or bearing, good wire surface finish. The pcd dies are available in two varieties, namely, compax and sumidia. Depending on their application are used for different wire drawings, these dies are widely used in non-ferrous wire like copper wire, stainless steel wire, aluminum wire, and tire cordet. The dies are especially good for larger sizes where demanding wear is a problem. advantages : excellent warefracture resistantmaximum die lifehighest machine efficiency with minimum down time

PCD Die Blank

Get Price Quote

Die Wire Spring

50 Per Number

25 Number (MOQ)