Shot Peening Machine for Mining Products

500,000 - 10,000,000 Per

1 Piece (MOQ)

Airless Shot Peening Machine

Get Price Quote

Best Deals from Peening Machine

Glass Beads Shot Peening Machine

2,800,000 Per Set

1 Set (MOQ)

Shot Peening Machine for Rods

250,000 - 400,000 Per Piece

Our company is reckoned as one of the prime Manufacturers, Exporters and Suppliers of Shot Peening Machine For Rods. Precisely engineered in different specifications, the Shot Peening Machine is an operating type machine in which rods are fed through diabola into machine. The rotating rods are shot peened to required intensity and come out from outlet portion. All shot peening parameters are monitored in the machine to achieve desired results. Our Shot Peening Machine For Rods is well equipped with Shot Classifier, Shot Velocity Controller, Shot Quantity Controller, Shot Direction Controller etc. It is appreciated for superb quality, user-friendly operation, high reliability and low maintenance. Further, customers can avail Shot Peening Machine For Rods at highly competitive prices. Shot Peening Machine For Rod is used to clean rust on rods and give hardness to the material.

Shot Peening Machine

Get Price Quote

Raw materials that we source from the trusted vendors are used as input in the production procedure and thus we check them against varied quality parameters before procurement. With the assistance of our modern transportation facilities, we are able to deliver the orders on time.

Automatic Glass Bead Peening Machine

Get Price Quote

MEC automatic glass bead peening machine is designed to peen API threads of drilling components as per MIL-S-13165 standard. To provide two axes shot peening operation for the generation of controlled compressive stress and to improve the galling resistance of the internal & external threads roots on the pipes at both ends. Machine is suitable for peening job of maximum size 12 mtrs [L] &12" Dia. Standard: Pneumatic operated front door for easy loading Motorized roller arrangement for job rotating 2 Controlled speed gun manipulation for OD & ID peening Quick change OD & ID peening pressure nozzles Large work envelope in cabinet High production machine Offline vibratory sieve classifier unit for size classification Offline spiral type separator for shape classification Gravity feed grit recovery system Easy part pixture change over Work car movement for extended length of job High volume pressure chamber for long duration peening Optional: Automatic shot peening media adder Rotary lance drive. Shot flow control magna valve Custom part holding fixtures

Shot Peening Machine

1,000,000 Per Piece

Shot Peening Machine

Get Price Quote

Features : We offer a wide range of Shot Peening Machines that are of high-quality standards and can be used in various areas including Military and commercial aircraft, Automobile transmissions, Helicopters, Rock bits, and Oil field equipment. Our Shot Peening machines remove the Tensile Residual Stress caused by various bending and heat treatment procedures. This leads to an increased life span of parts while working at their maximum load capacities. Our machines are capable of improving the lifespan of Landing gears, gearwheels, gear shafts, turbine blades of aircraft, valve springs, suspension springs, connecting rods, and many others. Our Team has vast experience in handling orders and providing customizations so that you can be satisfied. Once you place an order with Metablast you will experience pure satisfaction.

Shot Peening Machine

Get Price Quote

- Shot Peening machine is used for surface peening of leaf springs to give extra life to the spring. - The leaf spring is placed on the conveyor belt, which moves at a speed of 3 meters/minute. - In the main blasting chamber concave surface of the spring is bombarded with very high velocity shots. - The impact of the shots leaves a impinge impression on the surface which increases the fatigue life of the spring by 50% Main parts of the machine: Main chamber/ Blasting chamber: Here the spring is subjected to shot peening. The inner side is protected by liners made of rubber and M.S. Care has to be taken to see that the condition of the liner is inspected every week and necessary replacement be done wherever wear & tear is observed. Shot Peening Wheel: Here the shots are thrown at very high velocity by the wheel and blades. Main parts for inspection are: Cage, Impeller, Blades, bare wheel, bearing assembly, V belts. The blades should be balanced to avoid vibrations and breakage. Pneumatic Cylinder: This operates on compressed air, which is supplied through a solenoid valve. The main function is to start supply of the shots and stop supply when shutting off the machine. Separator: This has a screen to separate the big unwanted particle, which may have accidentally entered the shots. Bucket elevator: This conveys the shots from the bottom of the machine to the separator at the top. The bucket belt can be tightened by the screws at the top. The belt and the buckets have to be inspected every 15 days for wear. Screw conveyor: This conveys the shots to the bucket elevator. Main conveyor system: This conveys the leaf springs through the machine. There is a variable speed drive unit for controlling the speed of the belt. Doors: They are provided for inspection of the liners in the main chamber. These are fitted with limit switches, which provide safety that the machine will not operate when the doors are open.

Satellite Hanger Type Shot Peening Machine

Get Price Quote

This machine is especially suitable for automotive, aerospace industries for shot Peening of components such as big gears, gear shafts , crank shafts, axles etc. The Shot peening intensity of 0.7mm on A Almen Strips are attained in 3 minute cycle. Entire Cabinet & Hanger is manufactured with Mn Steel to protect front wear & abrasion & thus gives a long life to the machine. The machine is suitable for a hanger drum of Size 400mmx1200mm. Four such Mn hangers are provided on an Indexing Hanger Module of 1500mm. One Hanger is at loading and unloading station while the hanger opposite to loading unloading station is the Shot Peening station. Balance two stations are idle & Air Wash Station. The Machine is provided with 3 no. Blast Wheel Strategically placed to cover the defined hanger size of 1200 mm length and 400 mm dia. Each blast wheel is powered by 15 H.P. motor and fires Ten Tons Shots per hour per wheel. All the Blast Wheels are provided with Variable A.C. Drive to control the Shot velocity while Peening. The Hanger rotation is also provided with variable A.C. drive to control rotation of the hanger. Matching Shot Recovery system is provided with Screw Conveyor, Bucket Elevator, Rotary Screen Separator, and Vibratory Classifier with Sensors to give feedback of precise working of each application. Machine is equipped with Magna valve to control the shot flow rate. The machine has an intelligent PLC controlling system where the Shot flow rate of each Blast Wheel is permitted in a given band width. Alarms are generated if shot flow rate is less or more than the pre-set limits. The Shot Peening Machine is programmed for recipe. Just select the recipe No. and all set parameters like BW Speed, Hanger rpm Peening Time will be automatically selected by the PLC. A touch Screen user friendly HMI is provided with the machine to display various parameters and operation being run on the machine.

Shot Peening Machine

Get Price Quote

1 Piece (MOQ)

Tumblast Type Shot Peening Machine

Get Price Quote

We are offering tumblast type shot peening machine with auto loader controlled through plc.

Shot Peening Machine

Get Price Quote

CNC Ceramic Glass Bead Peening Machine

Get Price Quote

MEC CNC bead peening machine is designed for effective peening on aero engine component (Blade Airfoils). To generate the controlled compressive stress to the surface and to enhance the surface properties, increase fatigue strength by creating small pores, increase life of components and prevent galling, ferreting, cracking & corrosion.The system has capacity to peen upto 48" length of blade. SYSTEM FEATURES & BENEFITS Standard: 2-axis servo controlled reciprocation Variable speed turntable rotation Work car with manual winch for ease of job loading approach High volume pressure tank for long duration peening Quick change & accurate positioned 6 peening nozzles Colored touch screen HMI &Siemens PLC panel Efficient reclaimer with screening Easy part fixture change over Optional: Automatic shot peening media adder Closed loop air pressure control Magnetic separator Rotary lance drive Spiral type shot separator Vibratory sieve classifier unit Motorized work car movement

Shot Peening Machine

Get Price Quote

Shot peening is a cold mechanical process or technique to improve the fatigue strength of substance by air blasting with small spherical balls. Small dimples are formed on the surface of the peening part by the striking of tiny spherical balls.

Shot Peening Machine

Get Price Quote

Shot peening machine a complete line of standard Shot Blasting Machines and custom designed. its performance in the arena of manufacturing Spares for Shot peening machine .

Rod Shot Peening Machine

Get Price Quote

This machine, is continuously operating type, in which Rods are fed through diabola into machine. The rotating rods are shot peened to required intensity and come out from outlet portion. All shot peening parameters are monitoredin the machine to achieve desired results. Machine is equipped with Shot Classifier, Shot Velocity Controller, Shot Quantity Controller, Shot Direction Controller etc.

Shot Peening Machine

Get Price Quote

What is shot peening: Shot peening is a cold working process used to produce a compressive residual stress layer and modify mechanical properties of metals. It entails impacting a surface with shot (round metallic, glass or ceramic particles) with force sufficient to create plastic deformation. It is similar to sandblasting, except that it operates by the mechanism of plasticity rather than abrasion each particle functions as a ball-peen hammer. In practice, this means that less material is removed by the process, and less dust created.

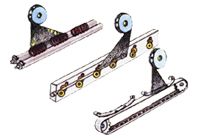

Airless Shot Peening Machine

Get Price Quote

Airless Shot Peening Machine The operator has to place the coil springs over the adjustable leaner rollers on which it rotates and moves forward. The springs enter in the cabinet where a pair of wheels shot peen the coil springs.

Peening Machine

Get Price Quote

MEC CNC bead peening machine is designed for effective peening on aero engine component (Blade Airfoils). To generate the controlled compressive stress to the surface and to enhance the surface properties, increase fatigue strength by creating small pores, increase life of components and prevent galling, ferreting, cracking & corrosion.The system has capacity to peen upto 48" length of blade.