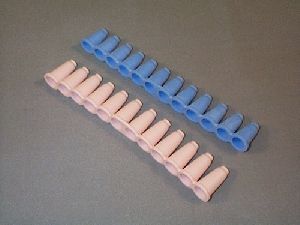

Suppository Moulds

390 Per Piece

2 Piece (MOQ)

Outfitted with ultra modern machinery and equipment, we are in the business of manufacturing and supplying an exclusive range of Suppository Molds. These molds are designed under the firm direction of the expert professionals using high quality materials. Our quality analysts check the molds on certain quality parameters to provide a flawless range to the clients. We offer our Suppository Molds at the market leading price and deliver to the clients within the committed time frame. Features: Long service life Easy to use Light in weight Further Details: The Suppository Molds that we offer are used extensively in several applications. These Suppository Molds are reliable and have a long service life. They operate flawlessly every time. Our Suppository Molds are of high quality and are easy to use. The Suppository Molds are quality tested at every stage to ensure that they conform to the Industry standards. Applications In pharmaceuticals In compounding.

Round Shape Tablet Punches and Dies

Get Price Quote

100 Piece (MOQ)

Best Deals from Pharmaceutical Dies

Camphor Tablet & Slab Dies

5,000 - 12,000 Per Depends on Size & Shape

1 Piece (MOQ)

Suppository Mould Brass

293 - 2,400 Per Piece

1 Piece (MOQ)

Suppository Mould Made from brass/gun metal machine made perfect shapes smooth and polished cavities. Nickel plated various capacities with a number of moulds in each set.

Tablet Die Punch

1,150 - 7,500 Per Piece

10 Set (MOQ)

Suppository Molds

Get Price Quote

Plain ONHS Pharmaceuticals Tablet Die Punch

1,300 - 1,450 Per Bag

10 piece (MOQ)

Suppository Mould

Get Price Quote

tablet punches and dies

1,000 - 2,400 Per Piece

1 Piece (MOQ)

Tablet Press Tooling - Die & Punch Precise Perfect Finish Tablet Press Tooling Application & Process : ACE Punches and dies are manufactured in-house with state of art machines. The raw material used in the production of tablets is compressed by a pressure of several tons on a small area of a few square millimeters, to produce a visually perfect tablet. There fore the Tablet press tooling is required harder and smoother and good finish surface. Prism has developed an advance technological system especially for manufacturing of precise, perfect and finished tablet tools. Salient Features : Choice for material of construction of Die and Punch- 1. OHNS (T) Oil Hardened Non shrinking steel (Tungsten) - AISI 012. HCHC - High carbon High chromium steel - AISI D3 Tooling size as per EURO, IPT Standards and Special tooling. Can be manufactured any shape of the tooling. Can be manufactured Multi tips and Polo type tooling. Careful matching of material and hardness. Trouble free fitting and removal Manufactured to the smallest tolerances. High Precision finish. Tooling Set A single tooling set comprises of upper punch, lower punch and die. These punches move vertically in turret bores through cams and compress to form a tablet. As per international standards, i.e. TSM (Tablet Specification Manual) and EU (Euro Standard), tooling specs have been standardized so that inventories worldwide can be minimized for tablet presses. All international manufacturers follow EU standards and TSM standards mostly followed in the United States of America and in Japan. Upper punch: Upper punch is fitted in the turret bore and moves vertically in bores during compression. Upper punches make the upper cavity of the tablet. It is fitted with key for alignment with die bore in case of shape punches. For round punches, there is no need of key in upper punches. Upper Punches travels 5-6mm inside the die bore during compression and as per the penetration setting done in a compression machine. Tip Length is shorter in the upper punch compared to the lower punch. Tip length of upper punch is generally 8mm-9mm. Lower punch: The lower punch is fitted in the turret bore and makes the lower cavity of the tablet during compression. Lower punch tip always stays inside the die bore hence there is no need of key in case of lower punch. Tip length is relatively longer in the lower punch as it has to cover the entire height of die and eject the tablet. The lower punch tip length is 25-28mm. Die: Die is fitted in the die plate. Die bore in die is actually where the filling of powder is done. Upper punch tip and lower punch tip compresses the powder in the die bore with the help of compression roller pressure applied on the head flat during compression to make the required shape of the tablet. Tooling Types There are different types of tooling i.e. D, DB, B and BB types. Apart from these standard types, there are FS tooling, BBS tooling, A tooling and Chinese standard tools which are totally different than International standard tools.

Confectionery Tablet Tooling

Get Price Quote

1 Piece (MOQ)

KanTaaiTi Pharmatech Confectionery Dies and Punches are well suited for high temperatures. Our Confectionery Tablet tools are resistant to corrosion and abrasion and are known for their robust physical properties and finish. These contain Glucose Tablet Tools, Naphthalene Balls Tablet Tools, Bakery Usage Product Tablet Tools, Detergent Tablet Tools, Salt Tablet Tools, and Sugar Boiled Confectionery Product Tablet Tools. Our range of tools meets the required cost, quality effectiveness and efficiency. They are easy to maintain, at the same time they also extend finely balanced coating that ensures unbeatable quality.

Round Shape Tablet Dies

850 - 7,500 Per Set

Round Shape Tablet global quality materials made from industry standard raw materials from reputed vendors. Close tolerances and exclusive artisanship is what helped the company to gain the huge customer base.

2 Hole Suppository Moulds

650 Per Piece

1 Piece (MOQ)

tablet punches and dies

Get Price Quote

Tablet Dies & Punches are devices having set of dies and punches which when pressed together form a hole in workpiece or deform workpiece in some desired manner. Chemical atmosphere, abrasive nature of product, turret speed, tonnage, cup depth, location of embossing, bisect land and physical condition of press are factors that go into selection of steel for manufacturing tablet dies & punches. Tablet dies & punches are available in various shapes like regular, irregular, core-rod tooling and sealed grove punch. Regular shapes of tablet dies & punches consists of round shapes dies & punches, capsule shapes dies & punches, oval shapes dies & punches and geometric shapes dies & punches. Irregular shaped tablet dies & punches produce tablets with different shapes like fruits, animals, parts of human body, vehicles etc. Irregular shaped tablet dies & punches are applicable in confectionery industries. Core-rod tooling shaped tablet dies & punches produce tablets having hole in center. Core-rod tablet dies & punches are applicable in confectionery and ceramic industries. Sealed grove punch shaped tablet dies & punches are used to prevent granule contamination during tabletting process.

SUPPOSITORY MOULDS (CAP 4 MOULDS)

Get Price Quote

Product Description Suppository Moulds (cap 4 moulds) Made from brass/gun metal, machine made perfect shapes, smooth and polished cavities, nickel-plated and various cap with a number of moulds in each set. Cap 4 moulds 1 gm 2 gm Suppository Moulds (cap 6 moulds) Same as above but with cap of 6 moulds Cap 6 moulds 1 gm 2 gm

Suppository Molds

Get Price Quote

The Suppository Molds that we offer are used extensively in several applications. These Suppository Molds are reliable and have a long service life. They operate flawlessly every time. Our Suppository Molds are of high quality and are easy to use. The Suppository Molds are quality tested at every stage to ensure that they conform to the Industry standards. Applications In pharmaceuticalsIn compounding

Multi Tip Die

3,000 Per Piece

Tablet Tooling

Get Price Quote

Apple Engineering Is the manufacturer and exporter of Tablet Tooling Punches and Dies. Apple Engineering Offers various types of machines needed in the pharmaceutical industries and laboratories. For Tablet Tooling Punches and Dies latest software Ideas/Cad system is used that allows both simple and complex designs to be rapidly developed and processed ensuring complete repeatability and accuracy.

Tablet Die Punches

Get Price Quote

We are specialized in manufacturing “b, “bb” & “d” type tablet tools as per tsm euro standards. The raw material used is of the highest standards ensuring optimum life of the tool. All the tooling manufactured has an excellent surface finish resulting in enhancement of the tablet produced by it in terms of appearance as well as accuracy. We also provide test certificate of the raw material and also provide its tracebility. We manufacture tablet tooling in ohns, d2, d3, s7, sus440, and bholer as per customer requirement. 1.round 2.shapes 3.special shapes

Tungsten Carbide Lined Tablet Dies

Get Price Quote

-4 Piece (MOQ)

Dear Sir/Madam We are Manufacturing and Exporters of Tungsten Carbide Dies/Liner for Aluminium Phosphate Tablet/ Tablet Compression Machine having Facility of Machines Like 1) FETTE Compacting 2) Cadmach Machinery Co Pvt Ltd 3) ACG PAM Pharma Technologies Pvt Ltd 4) Jayshree Tablet Science & Many More Machines as per your drawings with 40 Nos MOQ (Without Breakable)

Dr.Onic Suppository / Lipstick Mold 12 Hole With Fastener

Get Price Quote

1 Set(s) (MOQ)