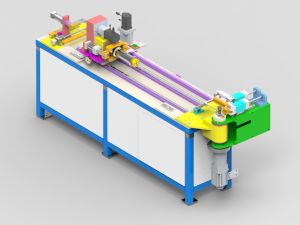

Section Pipe Bending Machine

55,000 Per Piece

10 Piece (MOQ)

single axis pipe bending machine

Get Price Quote

We are offering Single Axis Pipe Bending Machine to the clients. These Single Axis Pipe Bending Machines are capable of bending pipes or tubes from 4mm outer diameter to 164 mm outer diameter. These Single Axis Pipe Bending Machines feature color LCD touch panel for data entry and editing. Also, these Single Axis Pipe Bending Machines have hydraulic mandrel retraction. Features: Color LCD touch panel for data entry and editing Operation mode-manual/semi auto/fully auto 15 bends program Bend arm over ride switch to prevent bend arm/machine collision Programming in mm Program retrieval by alphanumeric code, password Hydraulic mandrel retraction Online/offline diagnosis mode Built in hydraulic oil cooling system Clockwise bending

Best Deals from Pipe Bending Machine

Three Roller Pipe Bending Machine

Get Price Quote

1 Piece (MOQ)

A three-roller pipe bending machine is a specialized type of section bending machine designed to bend pipes, tubes, and other profiles using three rollers to apply pressure. This type of machine is commonly used in industries like construction, automotive, shipbuilding, and metal fabrication, where precise and smooth curves are required in pipes or profiles. Key Components: Three Rollers: Top Roller: This is usually the adjustable roller that moves vertically (up and down) to control the bend’s radius. Bottom Rollers: These are fixed and rotate the pipe or profile through the machine while applying bending force. Electric or Hydraulic Power System: The machine can be powered by an electric motor or hydraulic system to move the rollers and provide the force needed to bend the pipe. Frame/Structure: A heavy-duty steel frame that holds the rollers in place and supports the machine during operation. Control Panel: Allows the operator to adjust the roller positions, bending speed, and pressure. Guide Rollers: Some machines are equipped with side guide rollers to help maintain the shape of the profile and ensure the bend is consistent. Types of Three-Roller Pipe Bending Machines: Manual: These machines are operated by hand, typically for small-scale or light-duty applications. Electric: Powered by an electric motor, these machines are more powerful and are used for larger pipes and more frequent bending tasks. Hydraulic: These use hydraulic power to move the top roller and provide force, suitable for bending larger diameter pipes or thicker materials. CNC: Computer-controlled versions that allow for precision bending and automation, often used in industrial applications where high accuracy and repeatability are needed. Working Principle: The pipe or profile is placed between the three rollers. The two lower rollers rotate the pipe while the upper roller applies pressure downward to bend the pipe into a curve or arc. By adjusting the position of the top roller, the operator can control the tightness of the bend. The machine can produce different radii and angles depending on the settings of the rollers. Bending Process: Loading the Pipe: The pipe or tube is placed between the three rollers, usually with the outer two rollers positioned at the desired spacing based on the pipe size. Adjusting the Rollers: The top roller is adjusted downward to begin bending the pipe while the two lower rollers rotate the pipe forward. Bending: As the pipe moves through the machine, the top roller continues to press the pipe, gradually forming the bend. Completing the Bend: The process continues until the desired angle or curve radius is achieved. Applications: Construction: Bending structural pipes for building frameworks, handrails, and curved beams., roll bars, and other curved components. Shipbuilding: Bending pipes and sections used in ship hulls and frames. Furniture: Used to form curved pipes and tubes for chairs, tables, and other metal furniture pieces. Aerospace: Bending precision pipes and profiles for aircraft parts.

3 Roller Pipe Bending Machine

Get Price Quote

1 Piece(s) (MOQ)

3 Roller pipe bending machine is tube bending and fabrication equipment, which uses the three powered rollers in triangular arrangements. These triangular arrangements work differently, the top roller of it is used to exert the downward pressure, and the other two mainly push up to deform the pipes. Looking forward to buy this to get all its benefits? Reach Bend-Tech India – one of the leading 3 Roller Pipe Bending Machine Manufacturers in Delhi/NCR. Our offered machine is designed and fabricated at our in-house facility under the supervision of our experts by utilizing the most advanced and innovative resources, which guarantees the reliability of the machine.Salient Features Of 3 Roller pipe bending machine: Dependable Performance: The performance of 3 Roller pipe bending machine is based on the working of it, which has to be hassle-free and this will guarantee you value for money. Require Low Upkeep: Since we pay attention to every single detail while designing the same, we can assure you that their working will be for years and years without the need of maintenance in the long term. Ensure Proper Bending: Wrinkle-free bending is a must for making the final product worth investing and this will take care of the same, without giving you any chance to complain. Application Areas: Four Wheeler Bumpers, Guard Railing Round Circle Bending If you are interested and have some specific demands, feel free to have words with our experts. As one of the paramount 3 Roller pipe bending machines Suppliers in India, we’ll assure the timely delivery, best quality and competitive pricing. Contact us for more details.

1/2 to 2 Inch Manual Pipe Bending Machine

13,500 Per piece

5 piece (MOQ)

Note : Price + 18% GST

pipe rolling machine

150,000 - 500,000 Per piece

1 Set(s) (MOQ)

We are bracketed among the renowned Manufacturers, Exporters and Suppliers of Pipe Rolling Machine. To cater the diverse requirements of the buyers, we offer different types of Pipe Rolling Machines like manual, mechanical & hydraulic three roller type pipe rolling machine. Bulk orders of these are processed by us as per the specific requirements of the buyers.

Pipe Bending Machine

Get Price Quote

1 Piece (MOQ)

Pipe Bending Machine

100,000 - 300,000 Per Piece

1 Piece (MOQ)

PLC, DCS, HMI & SCADA BASED CONTROL SYSTEMS FOR WATER CONTROL MANAGEMENT TRUNKEY PROJECTS (Installation & Commissioning Services) PIPE BENDING MACHINE AUTOMATION SYSTEM INSTALLATION, COMMISSIONING & TESTING SERVICE PROVIDER Details: Automatic Two Axis & 360 degree bend control. Stepper motor interface with PLC & SCADA System. Recipe management for different bend angles for different customers. Automatic Shift wise production reports generation. Auto job turning, clamping & bending for up to 15 nos. of successive cycles

Bamboo Strip Bending Machine

6,499 - 6,500 Per piece

1 piece (MOQ)

Key Features: Precise Bamboo Strip Bending: Our Bamboo Strip Bending Machine utilizes advanced technology to bend bamboo strips with accuracy and consistency. The machine applies controlled heat and pressure to the bamboo strips, allowing them to conform to the desired shape. This precision ensures that the bent bamboo strips maintain their form and structural integrity. Versatile Bending Capabilities: With our bending machine, you have the freedom to create various bending angles and curves. Whether you need gentle curves for furniture pieces or complex bends for architectural structures, our machine can accommodate a wide range of bending requirements. This versatility enables you to bring your creative ideas to life and explore different design possibilities. Adjustable Temperature and Pressure: The bending machine provides adjustable temperature and pressure settings, allowing you to customize the bending process based on the specific characteristics of the bamboo strips. This flexibility ensures optimal bending results while preventing damage to the bamboo material. You can achieve consistent and uniform bends throughout the bamboo strips. Efficient Production: Our machine optimizes the bending process, enhancing your production efficiency. It automates many of the manual tasks involved in bamboo strip bending, reducing labor costs and saving time. The precise and controlled bending ensures that the bamboo strips are ready for further assembly or incorporation into your products. User-Friendly Operation: While the machine harnesses advanced bending technology, it is designed for user-friendliness. The intuitive interface and controls make it accessible to operators with varying levels of technical expertise. Additionally, our team provides comprehensive training and ongoing support to ensure smooth operation and optimal results. Sturdy Construction: We prioritize durability and longevity in our machine design. The Bamboo Strip Bending Machine is built with high-quality materials, ensuring its stability and performance even under heavy usage. It is designed to withstand the demands of a busy production environment. Description Introducing the “Bamboo Strip Bending Machine” by Prashant Bamboo Machines – a specialized solution designed to bend bamboo strips with precision and ease. Our bending machine is specifically engineered to shape bamboo strips into curved or angled forms, allowing you to create unique and intricate bamboo structures and products. Why Choose Prashant Bamboo Machines? Industry Expertise: With years of experience in the bamboo processing industry, we possess in-depth knowledge of the specific requirements and challenges faced by manufacturers. Our machines are designed to meet these needs and deliver exceptional results. Quality Assurance: We are committed to providing machines of the highest quality. Each Bamboo Strip Bending Machine undergoes thorough quality checks and is built with precision to ensure reliable performance and longevity. Dedicated Customer Support: We value our customers and strive to provide excellent customer service. Our knowledgeable support team is readily available to assist you with any inquiries or concerns, ensuring a smooth and hassle-free experience. Competitive Pricing: We offer our Bamboo Strip Bending Machine at a competitive price, providing excellent value for your investment. Our goal is to help you optimize your production process without compromising on quality. Shape your bamboo strips with precision and creativity using the Prashant Bamboo Machines Bamboo Strip Bending Machine. Contact us today to discover how this specialized machine can elevate your bamboo processing capabilities and enable you to craft stunning bamboo structures and products.

Manual PVC Pipe Bending Machine

65,000 Per piece

1 piece (MOQ)

pvc pipe bending machine

350,000 Per Piece

1 Set (MOQ)

Manually Operated Hydraulic Pipe Bending Machine

Get Price Quote

As a prominent Manufacturer, Supplier and Exporter, we bring forth remarkable range of Manually Operated Hydraulic Pipe Bending Machine. We fabricate Manually Operated Hydraulic Pipe Bending Machine using quality raw material. Manually Operated Hydraulic Pipe Bending Machine, offered by us, is highly demanded by our clients present all across the globe.Highlights Durable Sturdy construction High efficiency Best quality

Motorised Pipe Bending Machine

Get Price Quote

1 piece (MOQ)

Hydraulic Pipe Bending Machine

Get Price Quote

Our company is engaged in manufacturing and supplying of Hydraulic Pipe Bending Machine. We present Hydraulic Pipe Bending Machine from 5 Tons -100 Tons for bending of circular tubes, rectangular tubes and bus bars, etc. This Hydraulic Pipe Bending Machine provides a precision finish with the desired design, shape and size. The Hydraulic Pipe Bending Machine is made from quality steel. Our range of hydraulic press is highly durable and requires minimum maintenance. Features : Hand Lever Operated Electric Push Button Operated PLC operated Seals : Hallite/Parker/Spareage etc. Cylinder material : En8/En9/ En19 Structure : Compact and fully stress relieved Hydraulic Valves/Pumps : Rexroth/Polyhydron/ Yuken/Vickers etc. With one year warranty Used for : Bending of circular tubes Bending of rectangular tubes Bending of bus bars etc. Steel industries Tube manufacturing industries Boiler manufacturers

Pipe Bending Machine

300,000 Per Piece

1 Piece(s) (MOQ)

CNC Pipe Bending Machine

Get Price Quote

1 set (MOQ)

Pipe Bending Machine

Get Price Quote

Our company offers high-quality NC/CNC Pipe Bending Machines. Our Hydraulic Pipe Bending Machines are extensively used for bending and molding pipes into desired shapes. They are manufactured according to the specific designs required by our clients. Crafted with top-grade raw materials, our machines ensure a long-lasting, trouble- free operational life. They are user-friendly and easy to operate. As one of the most renowned Pipe Bending Machine manufacturers in India, we proudly offer: • Single axis Pipe Bending Machines • Two axis Pipe Bending Machines • Three axis Pipe Bending Machines • Multi axis Pipe Bending Machines To inquire about the desired product(s), simply check the box and then click the "Inquiry Now" button provided below.

3 Roller Motorised Pipe Bending Machine

25,000 Per Set

1 Set (MOQ)

Special Pipe Bending Machine

Get Price Quote

Supported by superior transportation system, we can easily make safe and quick deliveries within the promised time span. We are backed by a well-structured and capacious storage unit wherein we store the entire lot in a secured manner. Moreover, we ensure complete security of the stored items. Details : The SSEGPL's pipe bending machine (PBM) is designed for Bending the steel pipe of various thickness and diameters with the high quality results. Fully equipped control panel with automatic emergency shut off that allows total control to the operator. Pin-up clamp automatically grips the pipe to prevent distortion. Operator can easily convert to another pipe size within the machine range is made by fitting an alternative bending set. SSEGPL's Pipe Bending Machine is capable to bend all grades of API-5L pipes withing its range. Stiff back rod allows the operator to do consistently uniform bending of pipes. Hydraulic driven winch for pipe movement. Each pipe bending machine requires a Bending Die Sets, a Mandrel and a Bending Belt (Steel Lined Choker Belt). Mounted with rubber tiers of steel tracks with a towing tongue. Available for pipe Sizes 6” To 60”.

Pipe Bending Machine

125,000 - 1,500,000 Per piece

1 piece (MOQ)