Automatic Top Locking Horizontal Injection Moulding Machine

800,000 Per Piece

1 piece (MOQ)

used plastic injection moulding machine

700,000 Per Piece

1 Piece (MOQ)

Best Deals from Plastic Injection Moulding Machine

Plastic Injection Molding Machine

Get Price Quote

SIGMA-125T Injection Moulding Machine

1,450,000 Per Piece

1 Piece (MOQ)

plastic injection molding machines

Get Price Quote

1 piece (MOQ)

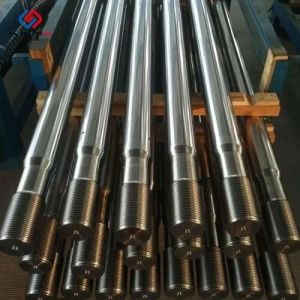

Injection Moulding Machine Tie Bar

Get Price Quote

Royal Mech Industries is the best company for getting polished injection moulding machine tie bars, you are in the right place. Tie-bar-less machine design can improve your efficiency and economy in injection moulding. The overall mould size that you are using in production dictates the size of the machine, not the maximum clamping force. The tie-bar-less machine allows the use of a smaller footprint since the mould can be fitted on the entire face of the platen without tie-bars getting in your way. This design also makes mould change and mould maintenance easier and allows for automation to enter from any angle without obstruction. Industrial and consumer plastic products now develop towards improved quality and diversification. Therefore, the task is on manufacturers to improve the quality of moulds. This is because moulds have direct involvement in product quality. This gave rise to the need for plastic injection mould polishing. Order the best products from us today.

horizontal plastic injection moulding machine

1,550,000 - 16,500,000 Per piece

1 Piece (MOQ)

Plc Contyroled Automatic Plastic Injection Moulding Machine is Designed for Continues Operation Having Production Rang from 50 Grm/100 Ton to 3.0 Kg 650 Ton Moulding Capacity. Machine is Capable Od Moulding Materialsuch as Nylone Thrmoplastic, Thermo Polymers, Polyurethane, Acrylic Polycarbonate Etc.

automatic plastic injection moulding machine

64,000 Per piece

1 piece (MOQ)

Industrial New Plastic Injection Molding Machine

Get Price Quote

The offered assortment of quality products is a result of complete quality inspections done at varied stages of sourcing raw material, which plays a vital role in delivering the finest products. Buyers can stay rest assured for the delivery of the orders as we are backed by the most sophisticated transit system. Features : High efficiency Proper functioning Long service life Additional Information : Item Code -320-210-750D

Horizontal Toggle Type Plastic Injection Moulding Machine

Get Price Quote

We offer horizontal toggle type plastic injection moulding machine. Standard features : - high production capacity with high power saving. - automatic mould height adjustment. - hydraulic, electrical, mechanical safeties. - large tie bar distance & platen area. - user friendly controls cause easier to operate. - auto lubrication system with grease. - low noising level - mould safety system - low maintenance cost electrical accessories : - plc controller b & r system or streamline controls pvt ltd. - electric wiring with finolex wire r.r cable. - electric accessories:tcselectron. - temp. Controller - servo motor : phase motion (tde macno),germany. - drives : tde make in italy - linear scale:gefran. - hydraulic injector through the linear scale mechanical accessories : - hydraulic valve & pump yuken india ltd. Or rexorth bosch ltd. - stainless steel material hopper with magnet - hard chrome platen tie barwith double grinding and micro finishing. - mould plate again casting sg iron casting, word class. - en-41b gas nitride screw barrel withmixing zone. - radial piston hydro motor made inintermation. - phosphors bronze bushing. - refilling screw rpm counting system. - 5 stage injection pressure system

plastic vertical injection moulding machine

Get Price Quote

Fully Automatic Horizontal Plastic Injection Molding Machine

Get Price Quote

We offer a wide range of Fully Automatic Horizontal Plastic Injection Molding Machine. Fully Automatic Horizontal Plastic Injection Molding Machine comes with a fixed van pump, variable displacement pump, servo system, full PLC controller, hydro motor, and an ejector. Additionally, Fully Automatic Horizontal Plastic Injection Molding Machine is equipped with auto load hopper and a dryer. Standard Features : PLC system ( colour display ) AC three phase induction motor Servo Motor AC drive Servo Drive Hydraulic Fixed Van pump Variable Displacement Pump Servo Gear Pump High chrome platted step less tie bar Larger opening stroke mould capacity and tie bar distance to accommodate large moulds Graded casting toggle, brackets and links with harden pin and bush Multi stage injection with speed & pressure Multi stage mould opening and closing speed & pressure Gas nitride steels screw barrel and cavity Part dropping sensor for single part Hydraulic & pneumatic core pulling device S.S. hopper with magnet grill Slide mechanism for hopper High efficiency and low power rate ceramic heater Centralize lubrication systems PID temperature controller for heaters Insulated heaters Screw back pressure control valve Cold start protection Air valve Water manifold 4 inout Hydraulic ejector Hydro motor for opening mold thread MCB control each heating zone Heater disconnection alarm Electrical and hydraulic (dump valve) interlock safety gate Ampere meter for heater Energy meter Oil temperature indicator Oil cooler ( water cooling type ) Injection Unit : Multi stage injection with variable speed & pressure Liner transducer to control programmable injection position Programmable holding pressure profile Programmable multi stage refilling Single injection cylinder unit Automatic purging Gas nitrated hardened screw and barrel Heater disconnection alarm Cold start screw prevention Pre-suck back function PID temperature control Sliding mechanism for hopper Screw back pressure control valve Clamping Unit : Case hardened pin & bush High tensile & hard chrome plated tie rods of larger diameters. Fully automatic centralization lubrication unit Multi stage mould opening and closing with variable speed & pressure Liner transducer to control programmable clamping system Five point toggle locking system Graded casting, Platen & toggle Motorized mould height adjustment for quick mould change Linear transducer for control programmable ejector position with variable speed & pressure Hydraulic ejector with multiple ejecting, oscillatory ejecting & holding

Two color plastic injection moulding machine

2,800,000 - 9,000,000 Per piece

1 piece (MOQ)

Plastic Injection Moulding Machine

Get Price Quote

Plastic Injection Moulding Machines

100,000 - 10,000,000 Per piece

We deal in used imported injection moulding machine

ROASTING SECTION MACHINE Manufacturers, Exporters

Get Price Quote

1 Piece(s) (MOQ)

Plastic Injection Moulding Machines

625,000 Per Piece

1 Piece(s) (MOQ)

DESCRIPTION/MODEL NATMEK 25 Injection A B Screw diameter mm 22 25 Screw L/D ratio - 17:07 15:05 Injection volume cm³ 30 38 Shot weight g 27 34 oz 0.9 1.2 Max injection rate cm³/s 33.8 43.28 Plasticizing rate kg/h 9.36 11.88 Injection pressure mpa 185 143 Screw speed rpm 0~165 Clamping Clamping force kn 250 Opening stroke mm 150 Platen size mmxmm 320x320 Space between tie bars mmxmm 200x200 Mold thickness mm 80-220 Ejector stroke mm 40 Ejector force kn 13 General data Max oil perssure mpa 14 Pump motor kw 2.2 Heating power kw 2.5 Heating zones - 2+nozzle Dry cycle time sec 1.1 Oil tank capacity L 85 Machine dimension mxmxm 2.62x0.62x1.21 Machine weight kg 1000

used plastic injection moulding machine

Get Price Quote

Used plastic injection moulding machine Five Stage Reduced Injection Pressure System, Linear Scale for Position Based Functions, Five Stage Reduced Injection Speed System.

350 Ton Plastic Injection Molding Machine

200,000 Per Set

1 Set(s) (MOQ)

Plastic Injection Moulding Machine

150,000 Per Piece

01 Piece(s) (MOQ)