Extrusion Tips

1,500 - 9,000 Per Piece

5 Piece (MOQ)

automatic plastic injection moulding machine

1,850,000 - 2,000,000 Per piece

1 Piece (MOQ)

Plc Contyroled Automatic Plastic Injection Moulding Machine is Designed for Continues Operation Having Production Rang from 50 Grm/100 Ton to 3.0 Kg 650 Ton Moulding Capacity. Machine is Capable Od Moulding Materialsuch as Nylone Thrmoplastic, Thermo Polymers, Polyurethane, Acrylic Polycarbonate Etc.

Best Deals from Plastic Machine

Film Stripping Machine

Get Price Quote

The Film Stripping Machine is used to measure the resistance of bituminous mixtures to stripping of asphalt from the rock particles. It is generally used to evaluate the mineral aggregate. We are the leading Manufacturer and Supplier of Film Stripping Devices. We use the best quality materials for manufacturing these Film Stripping Machines to guarantee full customer satisfaction. Major Components A rotating disc which rotates at a speed of approximately 100 r. p. m. The rotating disc carries four bottles. Supplied with a time switch. Suitable for 230 volts and single phase.

Single Screw Reciprocating Extruder (PCS 30)

1,675,000 Per set

1 set (MOQ)

Being an extraordinary figure in the industry, we offer a broad range of Single Screw Reciprocating Extruder (PCS 30) to our customers. This versatile and compact small scale extruder is used for customers sampling, research and development and color shade matching. Its scale up capabilities offer top notch efficiency and flexibility. It is easy to use, economical and user-friendly. At reasonable rates, we provide it in safe packaging. Details The Clarion make laboratory Kneader PCS 30 is a versatile, compact small scale compounding extruder for research and development, color / shade matching and customer sampling. This easy,economical, user-friendly laboratory kneader offers similar process characteristics as production scale PCS series machines. Samples from 300gms up to 40 kg/h. Based on its process scale-up capabilities it qualifies as a universal laboratory compounder offering a high grade of efficiency and flexibility. Standard Features and Advantages : Representative data from laboratory samples Throughput rates up to 20 - 40 kg/h Standard Split barrel design for easy access and cleaning, easy maintenance Fine temperature control with independent heating Cooling Zones Standard segmented screw, Liners for easy replacement of wear parts Variable screw speed to match desired properties Optional - Feed Screw with hopper can be installed for small batches Optional – Cooling Roller with belt for the small batch production. Detailed List of Basic Components Inlet hopper Complete barrel assembly with Screw Elements & Liners set fitted on barrel Discharge die with cooled chute Gearbox with Motor drive Main Drive Motor Operator panel with all standard accessories Volumetric Feeder Assembly (Optional) Chill Rolls (Optional) Base Table with Heat Cool Unit Leveling Screws

PVC TPR Shoe Air Blowing Injection Molding Machine

Get Price Quote

1 Piece (MOQ)

hydraulic pultrusion machine

1,100,000 Per piece

Frp Pultrusion Machine

Get Price Quote

technical specifications:- pulling capacity 1000 kgf to 4000 kgf. Pulling speed 0.02 metermin. To 4.0 metermin. Die clamping bed 800mm [w] x 1000mm [l] puller width 100mm - 300mm gripping by puller pads. Pulling action by mechanical geared power transmission clamping force by pneumatics cylinders heating zone 4 nos. Electrical power required 2.0 to 3.5 kw. Heating requirement (depending up on size of mould) compressed air required approx- 4-5 cfm, & 5 -6 kgcm² pressure. Accessories glass roving (creel) stands, roving guides, perform guides, resin impregnation bath, resin pressure injection system, glass mat roll feeding station, automatic section cutter, section conveying roller table, glass mat slitter & pultrusion mold, approximately overall dimensions length width height 2500 – 3000mm 600 – 1100mm 2100m

Electric Plastic Moulding Machine

64,000 Per piece

1 piece (MOQ)

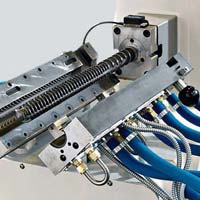

RSFgenius Series Filter Screen Changer

Get Price Quote

With regard to achievable product quality, economic efficiency and in terms of operator and maintenance friendliness, the RSFgenius offers unrivalled possibilitiesFully-automatic, pressure-constant, permanent process consistency-With regard to achievable product quality, economic efficiency and in terms of operator and maintenance friendliness, the RSFgenius offers unrivalled possibilities. This fully-automatic and pressure-constant filtration system can be used in virtually any application, for automation of the production process and for the manufacture of a high quality final product. The RSFgenius is particularly well suited for ultra-fine filtration, the filtration of thermally-sensitive melts and the filtration of materials with a high contamination level.The advantages of the RSFgenius Filtration System- Fully-automatic-The filtration system operates fully-automatically and ensures a 100% availability of the line. Depending on the contamination level, a screen change (which takes approx. 20-30 minutes) is carried out approx. every 1-16 weeks and has no influence on the production process and product quality. Constant-By always keeping the size of the active screen area constant, pressure, temperature, viscosity and throughput of the melt remain constant, which guarantees the highest end product quality. Quality-Optimal flow channel design and encapsulation guarantee lasting purity and quality of the melt after the screen changer. The short dwell time of the melt in the filtration system (< 1 minute) permits quick material or color changes. Filtration finenesses down to 1 micron are possible. Simple-Screen changes do not expose personnel and environment to any danger. With the fully encapsulated design of the RSFgenius, influences from the environment (e.g. moisture, oxygen) during the filtration process are excluded. Due to the very effective screen cleaning with high pressure impulses, screens are automatically re-used 100-400 times (depending on the filtration fineness). Compact-The small and compact design of the RSFgenius makes a simple and cost-efficient integration possible even in a very confined space. Thanks to the compact design and the high quality insulation, the energy consumption is extremely low. Mode of operationA high pressure segmental backflushing system purges the screen packs clean, shortly before their re-entry into the melt channel. A small, measured „shot“ of filtered polymer is taken from the „clean“ (filtered) side of the screen changer and injected with an adjustable pressure of approx. 30 – 80 bar backwards across the screen pack. The backflush is then ejected through the screen changer inlet block to the outside. Only a small segment (approx. 1 %) of the screen area is cleaned at one time. A defined quantity of material delivers a high energy cleaning impulse.DesignThe filter disk – on which the screen cavities are located in a ring pattern – is completely encapsulated by the two filter blocks. Screens can be inserted into the cavities by opening a small hatch door giving access to the cavities. The production process is not disturbed by the screen change procedure. Thanks to the modular design of this filtration system, it is possible to replace the few wearing parts (such as heater elements and bearing bushings) during operation. Continuous production over many years is thus made possible.VersionsModel versions with special performance features are available to suit the respective application: Very high filter surface exchange rate for highly contaminated materials Continuous back-flushing for extremely sensitive processes and polymers and/or extremely contaminated materials

plastic scrap grinder machine

48,000 Per Piece

1 Piece(s) (MOQ)

Vertical Plastic Mixer

Get Price Quote

1 Piece(s) (MOQ)

Cold Plastic Paint Removing Machine

380,000 Per Piece

1 Piece (MOQ)

Hydraulic Screen Changer

1,250,000 Per Piece

1 piece (MOQ)

Recycling Extruder Machine

1,650,000 Per Piece

1 Piece (MOQ)

Plastic Waste Shredding Machine

300,000 - 500,000 Per piece

1 piece (MOQ)

PET Plastic Color sorting machine

500,000 - 2,000,000 Per piece

1 piece (MOQ)

DK.1526D Digital Ultrasonic Plastic Welding Machine

2,500,000 - 900,000 Per Piece

Granule Mixer Cum Dryer

120,000 - 225,000 Per Nos

1 NOS (MOQ)

plastic extrusion machines

1,300,000 Per Units

Plastic Sheet Die Cutting Machine

Get Price Quote

Our expertise lies in designing and developing Plastic Sheet Die Cutting Machine of remarkable quality. We precisely design and develop Plastic Sheet Die Cutting Machine with the help of technocrats. Designed to cater emerging demands, Plastic Sheet Die Cutting Machine ensures efficient performance and minimizes operational cost. Chiller We provide accessories that optimize compressor efficiency. With the correct selection of these accessories, technically oil and moisture-free compressed air can be provided. Air/Water-cooled after cooler version Downstream compressed air filters High pressure air drier High pressure receiver Suilt-in oil and moisture separator

Plastic Rope Making Machine 2mm to 6mm

224,000 Per Set

1 Set(s) (MOQ)

Industrial Plastic Washing Machine

150,000 Per piece

1 piece (MOQ)

plastic injection molding machines

Get Price Quote

1 piece (MOQ)

Heat Seal Film Lamination Machine

Get Price Quote

We are also leaders in manufacturing Heat Seal Film Lamination machine known to huge customer base worldwide. It is used for double sided Paper Lamination which is then sealed by its corners. This machine is basically used for special jobs, mainly used for making table mats, identity card, Laminated Document Papers etc.

Plastic Waste Washing Machine

150,000 - 400,000 Per Piece

1 Piece (MOQ)

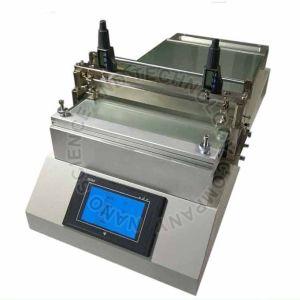

NST-MS-GD200 Small Battery Film Coater Machine

350,000 - 450,000 Per Set

1 Piece (MOQ)

Jumbo Bag Plastic Waste Shredder

Get Price Quote

1 piece (MOQ)

GOYUM is a manufacturer, exporter & supplier of Jambo Bag, Plastic Waste Shredder. GOYUM Shredders comes in Dual Shaft Shredding System and are ideal solution for Jambo Bag, Plastic Waste Shredder. Features : Low speed, high torque shredders Energy efficient Friendly in operation Automatic reversal system for overload protection Innovative cutter locking system Robust design for less maintenance and operating cost Wear resistant cutter & spacer Flexibility in range of hopper for bulky items Technical Specifications Model Motor Capacity GOYUM 30 50 HP (2 Motor Required) 2 – 3 Tons/Hour GOYUM 60 60 / 75 HP (2 Motor Required) 5 Tons/Hour GOYUM 90 120 HP (2 Motor Required) 20 -25 Tons/Hour

Plastic Bag Sealing Machine

Get Price Quote

We manufacture Plastic Bag Sealing Machine for various budgets and requirements and make it available in the market at competitive prices. Our Plastic Bag Sealing machine is specifically designed for meeting the requirements of diverse industrial segments. Product Details Super impulse sealers Designed specifically for packaging and sealing applications Can seal up to 1000 gauge Polyethylene, PP, HDPE, HM and other thermoplastic material films Fully transistorized circuits Manual foot pedal operated Light in weight Easy operations Technical Specifications Mains Supply : 230 volts A.C., 50 Hz, 1 � phase, Seal Length : 310 mm, 620 mm, 770 mm, 920 mm, 1200 mm. Sealing Width : 2, 3 & 5 mm. Average Consumption : 300W, 500W, 700W, 900W, 1200W Two parallel seals offered Engraved & Ribbon seals Variety Available Horizontal Foot operated bag sealing machine Foot Operated Vertical Bag Sealing Machine Portable Hand sealer Used for Packing of Tea & Coffee Biscuit & Confectionery Dairy products Auto Parts Book stores Soaps & Detergent. Electrical & Electronic parts Pharmaceutical Medicine, etc.

Full Auto Plastic Cap Sealing Machine

220,000 Per Piece

1 Piece (MOQ)

Monolayer Blown Film Extrusion Machine

500,000 - 2,000,000 Per piece

1 Piece (MOQ)

Recognized Manufacturer, Supplier and Exporter of Monolayer Blown Film Extrusion Machine, Monolayer blown film machine price in india, Blown Film Extrusion Machine at Best Price in India, 3 layer blown film extrusion machine, Blown Film Extrusion Machine manufacturers in ahmedabad.Salient Feature Screw Type :- Barrier EN41B material Gas Nitride Screw and Barrel Helical Gear Box AC Drives for Extruder and Take-Up Lowest Energy Consumption High Output Space Saver Other Variant Twin Die Extruder 2 color Strip type Extruder with Single color online printing Optional Accessories Duplex Winder Corona Treater Rotating Die Gusset Unit Hopper Loader