Plastic Granule and Powder Mixer Machine

Get Price Quote

1 Piece (MOQ)

PLASTIC GRANULE AND POWDER MIXER Color mixer is widely used for mixing, stirring powder and granule materials. Mixing can be done in a short period of time and it has high performance. Both mixing barrel and the mixer are made up of stainless steel and polished. A vertical reducer motor is adopted to ensure low noise and durable. Vertical color mixers are widely used in plastic injection, plastic recycling, powder metallurgy, pharmacy chemicals, foodstuff and ceramic ware. Available from 25 to 100 kg capacity.

Plastic Crushing Machine

80,000 - 300,000 Per Piece

1 Piece (MOQ)

Best Deals from Plastic Processing Machinery

Automatic Thermoforming Vacuum Packaging Machine

2,500,000 Per Piece

1 Piece (MOQ)

Aluminium extrusion dummy block

1 - 50,000 Per Piece

2 Piece (MOQ)

Single Screw Extruder Machine

800,000 - 1,500,000 Per Piece

1 Piece (MOQ)

Extrusion Tips

1,500 - 9,000 Per Piece

5 Piece (MOQ)

Plastic Injection Molding Machine

Get Price Quote

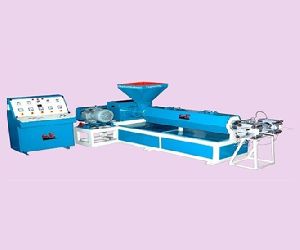

Single Screw Extruder - (reciprocating)

12,000 Per 92000 Set

1 Set(s) (MOQ)

We are offering single screw extruder - (reciprocating) etc. We are the only manufacturers of these type of extruders in India. The basic construction is same as buss swiss. We have range from 30-1200 kgs hr. Machines for powder coatings powder mfg., Toners, Plastic master batches, Chocolates, PVC granules, food processing, etc.

Plastic Tap Shower

47 Per Piece

10000 Piece (MOQ)

PLC Plastic Injection Moulding Machine

850,000 Per Piece

1 piece (MOQ)

plastic nylon extruder machine

2,500,000 - 12,000,000 Per Piece

1 Piece(s) (MOQ)

HDPE Plastic Drum Blow Molding Machine

650,000 Per

1 Piece (MOQ)

Plastic Mixture Machine

30,000 Per Piece

1 Piece (MOQ)

Recycling Extruder Machine

1,650,000 Per Piece

1 Piece (MOQ)

CSFprimus Series Filter Screen Changer

Get Price Quote

Patented Rotary Filtration System with large active screen area and two working positions.Continuous and fully-automaticPatented rotary filtration system with large active screen area and two working positions. The filter disc is divided into two zones, which can be alternately moved into the melt channel. On request (e.g. for batch or roll changes) the positions and thus all screens in the melt channel are automatically changed. The melt flow is not interrupted, so that downstream components do not have to be restarted afterwards. Filter elements can be replaced at any time between two changes.The advantages of CSFprimus screen changers Compact-The small and compact design of the Rotary Filtration Systems makes simple and cost-efficient integration possible even in a very confined space. Sturdy-The metallic sealing system is highly wear-resistant. It guarantees leak-free operation even with low viscosity melts up to 500 bar. Streamlined-The rheology of the melt channel and the inner parts of the screen changer can be individually adjusted to the specific requirements. Uncomplicated-A screen change can be carried out automatically at any time without interrupting the melt flow. In case of a change, all screens in the melt flow are completely exchanged. Such a change should preferably take place during roll/batch changes. If more frequent changes are required during the production batch, a pressure-constant system (SFneos, SFXmagnus or RSFgenius) should be used. The filter disc is divided into two filter segments which can be alternately introduced into the melt channel. The change is done fully automatically. The system is driven hydraulically or pneumatically.The segment, which is not located in the melt channel, is completely accessible, so that the operating personnel can replace the filter elements at any time between changes. On request, a version with removable breaker plates is also available, so that even demanding colour changes can be carried out in the shortest possible time.During the change itself, the melt flow is not interrupted, so that downstream components generally do not have to be restarted after the change.

Plastic Mixture Machine

Get Price Quote

Electric Plastic Moulding Machine

64,000 Per piece

1 piece (MOQ)

Magnum Plastic Moulder is an Electric Plastic Moulding Machine. This Machine is Small in Size, Electrically Powered and offers Semi-Automatic plastic moulding facility.Our machines are suitable for the manufacturing of all types of plastic parts for Industrial, Commerical, Domestic and other items like toys and engineering parts. With our machine, one can produce produce itmes like Data Cables, 2 Pin Power Cable and 3 Pin Power Cable ete,Advantages of our machine are, it has Automatic Granule Feeding and injection features. This machine is small, consumes less Electricity, and occupies less space, thereby incresing your profit margins.You can manufacture all plastic items fast, effecinetly without the need of a skilled operator. Any layman can learn andoperate this machine in just 2 hours.Please note, this is a Pure Electric Machine, there is No need of any Hydraulic or Pneumatic Pump / Motor required.

Hydraulic Screen Changer

1,250,000 Per Piece

1 piece (MOQ)

Plastic Recycling Machine

98,000 Per piece

1 piece (MOQ)

The Plastic Recycling Machine is a versatile and efficient tool designed for recycling plastic waste. Equipped with a robust 5 HP motor, this machine is capable of handling a wide range of plastic materials, ensuring effective recycling and waste reduction. The machine's production capacity is impressive, with the ability to process 70 to 80 kg of heavy-weight material per hour. This makes it ideal for handling substantial amounts of plastic waste in a short period. For lighter materials, the machine maintains a production capacity of 20 to 22 kg per hour, demonstrating its adaptability and efficiency across different types of plastic waste. Designed with durability and high performance in mind, the Plastic Recycling Machine is an essential asset for businesses and facilities focused on sustainable waste management and recycling practices. Its reliable and consistent performance helps optimize the recycling process, contributing to environmental sustainability and cost-effectiveness. This machine is an excellent choice for those looking to enhance their plastic recycling capabilities and reduce their environmental footprint.

Plastic Waste Recycling Machine

Get Price Quote

Specifications PE/PP film recycling PE/PP bottle recycling PET bottle recycling Other plastic The main components of the machine Crusher Hot washing machine (can be chased according the customer’s request) Washing machine Drying system