Plastic Recycling Plant

400,000 Per Piece

1 piece (MOQ)

Plastic Recycling Plant

1,000,000 - 1,500,000 Per unit

1 set (MOQ)

Best Deals from Plastic Recycling Plant

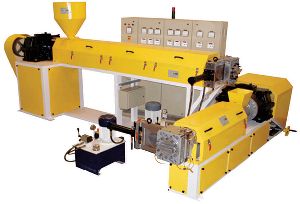

Mother Baby Waste Recycling Extrusion Line

185,000 Per piece

1 piece (MOQ)

Mother-Baby Waste Recycling Extrusion Line (Re-processed Granule Production Line) is consists of Two Extruders, two screen changers, Die and Die face cutter etc. controlled by duly synchronized Electric Panel to produce high quality ( next to virgin ) granules for the specific requirements of the customers. Available in different Models according to production capacity.

Plastic Granule Recycling Plant Without Agglomeration

Get Price Quote

1 Piece (MOQ)

PLASTIC WASTE LUMPS PLANT

Get Price Quote

Features Suitable for different kind of plastic lump materials, are able to separate high density and dirt material. Suitable for plastic lumps, plastic bottles and etc. With high speed washing machine, enable plastic materials inside the machine to be twisted, washed and separated dirt. Separator to extrude waters Whole set of electric facility are with automatic startup to protect wires in safe.

Plastic Recycling Plant

Get Price Quote

The Plastic Recycling Plant, we offer, is set in accordance with the international standards. It stands high in quality as well as innovation. Its production capacity is ensured to be exactly the same as desired. And its efficiency surfaces from the fact that its results are flawless. We are standing amid the leading Manufacturers, Exporters, and Suppliers of Plastic Recycling Plants from Uttar Pradesh, India. This plant consists of following : Plastic crusher: it crushes plastic containers along with lid. The capacity of the machine is crushing plastics of 40 ton scrap battery in 24 hours. Electricity requirement 40 kW; manpower required one man; machine is water cooled; so, lead dust does not spread around; crushed plastics automatically fed to washing machine. Plastic washing machine: it washes plastic and separate lead dust from crushed plastic. Water is reused and lead dust/ bottom sludge can be collected from this operation. Later it can be sent be to lead furnace for recycling. Plastic rinsing machine: plastic washing machine feeds automatically to this machine with crushed and washed plastic, it rinses in water, and remaining lead dust is separated. Water pumps: two submersible pumps are used in system along with cyclone The whole line is fully automatic and it has characteristics of high efficiency, low noise and easy operation. It adopts hot alkaline water washing to get good quality. Any acid or lead dust is removed by friction washing. Crushed plastic is transferred automatically by inclined material conveyor. Inclined conveyor shifts plastic pallets to rinsing machine. Rinsing machine washes again in clean alkaline water. The pH level is continuously monitored by electrical control panel. Soda ash is charged to washing tank so alkalinity is maintained. This alkaline water neutralizes acidic film formed on the surface of plastic and subsequently clean it. Man power required two men. Lead dust emissions to air is nullified due to its unique design criteria. All emissions are suppressed into water bath so no lead dust is emitted to air. So no particulate matter in the air is created. Lead dust is either transfers with water to E.T.P. Plant or settles down after de-sulphating. Battery container of 40 ton battery/ day.

Plastic Recycling Plant

Get Price Quote

Plastic Recycling Plant

2,200,000 Per Piece

Plastic Recycling Plant

2,000,000 - 8,000,000 Per Plant

We are engaged in manufacturing and offer premium quality Waste Plastic Recycling Pyrolysis Plants, which are used to convert waste plastic into useful fuel by pyrolysis. Furthermore, the pyrolysis oil can be utilized as fuel for boilers, furnaces and other industrial heaters.

Pet Bottles Recycling Plant

Get Price Quote

1000 kg per hour capacity pet bottles recycling plant for sale, installed in 2013, total power load 232 hp complete line from bale breaking, washing to material bagging system related fixtures, accessories, cables and panel board, in excellent working condition.

SMT HDPE Plastic Recycling Plant

1,250,000 Per Set

Our company is widely appreciated in offering Plastic Processing Machine to make plastic dana/ granules for reuse of it . Plastic Processing Machine is made from very high quality raw material and latest technology which ensures hassle free work performance at its user end. Offered range widely finds applications in various industrial sectors. Features: Easy to maintain Perfect result Long working life

Plastic Recycling Plant

2,551,000 Per Piece

1 Piece (MOQ)

Applications of Plastic Recycling Machine :- Material: All kinds of plastics waste Online Force Feeding Film Trim, Tape Trim without cutting agglome For the plastic waste of higher moister, heavy printing, heavy contamination For low bulk density material less than < 0.5 gm/cm3 Features of Plastic Recycling Machine:- Both the Extruder has Screen Changer so dual filtration Main Extruder can be provided with Force Feeder Main Extruder is vented type Both Extruder are Synchronised speed through AC drive Filter Choking Alarm & Triply Facility

Plastic Recycling Plant

500,000 Per Piece

Plastic Recycling Plant

2,500,000 - 5,500,000 Per Piece

1 Piece (MOQ)

PLASTIC RECYCLING PLANT : Recycling / Granulating / Pelletising Plant / Machine (EXTRUSION PLANT) Sai Machine Tools’ Recycling plant / machine are High Capacity Machines with Minimum Electricity Consumption Guarantee. Sai Machine Tools recycling plant / machine are with Vented Extruders which ensures that the complete moisture, chemical inks and volatiles in the material are removed by the venting system to ensure the best quality re-processed granules.

Plastic Recycling Plant

400,000 Per unit

LLDPE Recycling Plant

1,451,000 Per Piece

01 Set (MOQ)

Double Extruder Plastic Recycling Plant

Get Price Quote

1 Piece (MOQ)

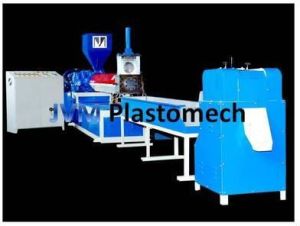

Plastic Recycling Plant

Get Price Quote

Advanced design, superior quality, and competitive price are some of the unique features of our Plastic Recycling Plant. We design wide range of Plastic reprocess plant with different recycling requirements (65 mm to 150 mm). Production capacity of the Plastic Recycling Plant is 1500 kg to 5000 kg per day. These Plastic Recycling Plants have advanced machinery. We have our office in Bhadeli at Valsad, in the field of plastic processing system has evolved itself as reputed and renowned organization in plastic industry. We capitalize on the hand on industry experience, profound understanding of transitional economy and morder analytical tools to provide "Industry specific" solutions to our valuable clients. Features Screws & Barrels are made of special & high quality alloy steel for long term performance. Gas Nitrided screw & Hardened barrel. Helical Gear Box & Electrical motor. Screen charger (Hydraulic / Manual). Power saver & ceramic Heater. (Power saving) Power Saver Ceramic Jacketed Heaters [ Power Saving Upto 30% ] Digital panel board with thermocouple system. Pressure transducer ( hooter) for die for additional safety..[ optional item ] Water tank [ stainless steel 304 ] Pelletizer [ Cutter ]

Plastic Recycling Plant

Get Price Quote

Recycling Line with Japanese Technology Developed for Plasticizing & Recycling of LDHDHMHDPP PS FilmBOPPPP Film Machine suitable to process materials in the form of MonoMultilayer Film Waste Highly Printed Film Waste Metalized Non – Metalized BOPP-CPP All the Oriental Product – MonofilamentMulti Filament Non-WovenWoven or Tape or Raffi

Plastic Recycling Plant

2,200,000 Per Set