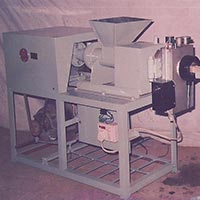

Soap plodder machine

150,000 Per piece

1 piece (MOQ)

plodder machine

215,000 Per Piece

1 Piece (MOQ)

Best Deals from Plodding Machine

Soap plodder machine

Get Price Quote

We Supply Machinery For The Soap Industry Where Soap Plodder Machine Is An Essential Part.

Twin Worm Simplex Plodder

150,000 - 500,000 Per Inr

After the sigma mixer the mixed mass is passed through this machine where the material is extruded into shape of noodles. In toilet soap and laundry soap production, Soap Pellets Pneumatic Transporting System is used to transport soap noodles. Features : Strong construction High performance Robust structure Power efficient

Plouder machine

Get Price Quote

Toilet Soap Plodder

135,000 - 150,000 Per pc

1 Piece(s) (MOQ)

Plodding Machine

390,000 Per UNIT

detergent cake plodder machine

90,000 Per Piece

1 Piece(s) (MOQ)

Duplex vacuum plodder machine

650,000 Per Piece

1 Piece (MOQ)

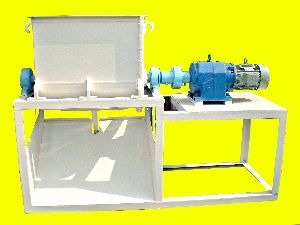

Automatic Soap Plodding Machine

295,000 Per Piece

5 Piece(s) (MOQ)

Owing to a wide distribution network, our company is bracketed with prominent Suppliers of Automatic Soap Plodding Machine. Customers are free to place small as well as bulk orders, timely deliveries of the same are our topmost priority.

Twin Worm Noodle Plodder Machine

Get Price Quote

Duplex vacuum plodder machine

405,000 Per Piece

detergent cake plodder machine

Get Price Quote

We are connected with well-known transport providers to make sure the distribution of deliveries is done out without a problem and on time. We ensure that the products will remain in a safe condition and for this; we have hired experts who keep a strict vigilance on the entire unit. Moreover, our unit is timely upgraded ensuring more safety. Our detergent cake plodder machine is available with a quality warranty of 12 months against any manufacturing defect.

simplex plodder machine

300,000 Per Piece

1 Piece(s) (MOQ)

Plodding Machine

150,000 Per Piece

Duplex Plodder Machines

Get Price Quote

We are instrumental in offering to our clients duplex plodder machine that is designed in compliance with set industry standards. This range is heavily used for manufacturing toilet soaps. We process this range in different via refining of the product through refining screens of different mesh and is forced out of the perforated disc. It results in converting the mass into different noodles of varied length and thickness. This machine is offered in the following capacities: 100 mm(4") 150mm(6") 200mm (8") 250 mm (10") 300mm (12")

simplex plodder machine

Get Price Quote

We are manufacturing and exporting a high end quality range of Single Worm Simplex Plodder. In this machine, materials are squeezed out in the shape of noodles. These machines are manufactured in compliance with the set industrial norms and standards using finest quality materials sourced from the trusted vendors.

simplex plodder machine

50,000 - 3,000,000 Per Units

Soap plodder machine

Get Price Quote

Backed by rich industry exposure, we are engaged in offering an extensive range of Soap Plodder Machine. Features: Attractive pattern Lightweight Efficient functionality Less maintenance Precise designing

Twin Worm Simplex Plodder

Get Price Quote

Twin worm simplex plodder / Pelletizer takes up refines the material from mixer The mixture is extruded by twin screws through the fine orifices of noodle plate Twin cylindrical barrel made of high thick SS 304/ MS and precision machined inners Barrel is constructed with thick back flanges to match to the twin output gearbox The barrel is jacketed and pressure tested for chilled water circulation Twin screws left and right flutes are designed with reduction pitch Screws are solidly casted SS 304, X ray tested with flights for positive extrusion Spider plates support the screws with SS pin and Teflon bush supports The worm shaft is supported at the end through heavy duty thrust bearing housing Main motor : Crompton / Kirloskar make 1440 rpm 3 phase Helical Gear box-Radicon/Shanthi/Elecon fitted with sturdy double output gear box Rotary SS shredders fitted on worms cut equal lengths of noodles