Post Forming Machine

Get Price Quote

1 Piece (MOQ)

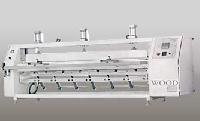

Post Forming Machine

350,000 Per Piece

1 Piece (MOQ)

Best Deals from Post Forming Machine

Post Forming Machine

Get Price Quote

Post Forming Machine

Get Price Quote

Post Forming Machines are widely used to shape laminates as per the underlying surface and their electrically heated pressing beam helps further curing of semi-cooked laminates for joint-less edges.

Evaporative Cooling Pad Making Heating and Forming Machine

Get Price Quote

D1 Windows POS Machine

45,000 Per Piece

1 Piece (MOQ)

Post Forming Machine

Get Price Quote

Silent Features : Automatic Post forming cycle Pneumatic cylinders to apply uniform pressure on job for effective bonding of Laminates Facility for manual and Automatic Hard chrome plated heater bar for smooth operation and long life Mechanical drive control Drive motor with brake is provided to avoid slippage of rotary part

Post Forming Machine

Get Price Quote

Features : Sandeep Post Forming Machine can perform various types of Post Forming Operators such as Bull Nose / Peocock Nose / Half Round / Quarter Round / Double Quarter Round Etc. The Post Forming Operators can be done on One or Multiple Nos. of Pcs together in one Line. The Machine is very easy to operate & doesn’t need any skilled operator. The Control of the Machine is by a PLC Which has a option to choose the various Shapes. The Time setting on the Various Position of Particulars shape can be set in the PLC of the machine. The Position of the Moving Arm/Hotting Pad is controlled by the PLC and whole operation completes automatically.

Post Forming Machine

Get Price Quote

Post Forming Machine

Get Price Quote

We are counted amongst the foremost manufacturer and supplier of Post Forming Machine. This machine can be used by the furniture industry for different wood works. In order to meet the exact requirement of our clients, our quality controllers check its quality against varied parameters. The machine we offer to the clients is well fabricated by our skilled engineers using the finest quality of raw material and cutting edge technology. Furthermore, it is available with us at industry leading prices.

Fully Automatic Post Forming Machine (2600mm)

Get Price Quote

Specifications Max workpiece length2600mmMax Workpiece thickness76mmWorking table height900m/sMax temperature210oCMax power6kwReducer motor power2.2kwAir pressure0.6MPaOverrall size3600x1200x1750mmNet weight1100kg

Earring Posts Machine

Get Price Quote

The STI200 model machine makes earring posts from the wire. After loading the coil of wire, the machine automatically rolls, cuts and collects the post without any waste or loose of material. It is possible to use any kind of metal wire, without a constant hardness and with different diameters without any mechanical adjustments. The inno- vative hammering system makes single or double cyrcular grooves and it is possible to adjust the groove depth and the lenght of the post. On the machine there is a settable electronic piece coun- ter and can be equipped with the stamping group with custom trade mark and stamp.

Post Forming Machine

Get Price Quote

8 pneumatic cylinders for uniform pressure on work-piece through forming rail for better bonding of laminate. Facilities for dry runs and manual runs provided for settings and trials. Auto post-forming cycle with variable heating time, stop and go time & holding time, can be adjusted to profile. Drive motor with brakes, to avoid slippage of rotary motion of the heater frame.

Post Forming Machine

Get Price Quote

Post Form Machine

Get Price Quote

Post Forming Machine

Get Price Quote

Earring Posts Machine

Get Price Quote

Earring Posts Machine of wire, the machine automatically rolls, cuts and collects the post without any waste or loose of material. It is possible to use any kind of metal wire, without a constant hardness and with different diameters without any mechanical adjustments. The inno- vative hammering system makes single or double cyrcular grooves and it is possible to adjust the groove depth and the lenght of the post. On the machine there is a settable electronic piece coun- ter and can be equipped with the stamping group with custom trade mark and stamp.

Post Forming Machine

Get Price Quote

With complete functions and reliable performance, it is the best choice for office furniture and modern kitchen cabinets. With good flexibility, Multi-shapes materials, it is very suitable for different laminated materials.

Post Forming Machine

Get Price Quote

manufacture we would like to present the most advance fully automatic controlled Post forming machine to our esteemed customers It is mainly used in wood working industries in India & all across the world. It encloses a PLC Control panel with capacity of 15 job programs. There is automatic post forming cycle for variable heating time adjustments. It has a pressure clamp with the Soft cotton wrap to grip the job properly & cotton for avoid the job damage. Also there is a Pneumatic gauge with the cylinder for repetitive job setting. There are 8 pneumatic cylinders that apply uniform pressure on job for well-organized laminate bonding. The job caring capacity of UPF 1000 is 300 mm to 2440 mm length; 16 to 125 mm thickness & 150 mm width. It includes a lifelong heater bar with the maximum 200 ⁰c heating temperature. it also has a drive motor which control the limit switch. Our machines are best at performance, durability & low maintenance cost.

Post Forming Machine

Get Price Quote

1. First Postforming machine to be manufactured in India 2. More than 500 users across India and abroad 3. PLC Programmed machine for fully automatic operation 4. Simple yet robust design for trouble free performance over prolonged period 5. Available in Three Phase as well as Single Phase model Post Forming Machine is chiefly used for bonding of flexible laminate with molded edge of the particle board / MDF board or Ply. Bonding can be full round, half round or bull nose type. We provide two standard modes of operation namely, manual mode and auto mode. In manual mode, all the functions are carried as per the switches pressed by the operator. This is mainly required for bull nose type of job setting. Our Post Forming Machine is operated by the Programmable Logic Controller (PLC). Normally our first program is set for the full round job and second program is for the half round job. The type of job can be selected as per the requirement. The remaining seven programs out of the nine can be customized as per the job requirement. We teach how to program the machine when we come for the installation. When the cycle is started in auto mode, all the operations are carried out in series like clamping, the heater bar forward, and slowly it covers the entire surface to be manufactured. Finally the release of heater bar and de-clamping takes place and the machine cycle comes to the initial/start position. Post Forming Machine Salient Features: 1. Three (3) clamping cylinders for better work piece holding. 2. Eight (8) cylinders for heater bar operation to ensure uniform pressure. 3. Short job / Long job selection. 4. Full round / Half round setting. 5. Ground and hard chrome plated heater bar for smooth operation and long life. 6. PLC Programmed machine for fully automatic operation. 7. 9 standard programs can be stored. 8. Reputed brand raw material used for manufacturing. 9. Personal attention while manufacturing the machine. 10. Special heater construction for uniform heating. 11. Separate control panel for ease of use. 12. Standard electric circuit. Post Forming Machine: Technical Specifications Max. Workpiece length:2400 mm Max. Work piece length(Recommended): 600 mm Min. Work piece width:160 mm Max. Work piece thickness: 100 mm Min. Work piece length:16 mm Connected load: 3 KW Electric Supply: 3 Phase 415 V AC Other voltages optional Compressed Air Requirement: 30 LPM at 6 bar (Specifications are subject to change without prior notice.)