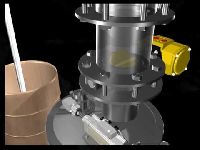

powder charging system

100,000 - 500,000 Per No

1 Set (MOQ)

To charge powders from drums/ sacks to silos/ reactors at rates exceeding 2000 kg/hr and over 25 meters. Easy to use. Easy to wash. You can dismantle the whole system in under 3 minutes for washing. No bulky valves/ electrical to be dismantled. All controls are mounted in convenient Starter box. Easy to replace PTFE cartridges for filtration. Optional HMI for multi product setups. CIP/ SIP options possible. High Technology powder conveying in one simple package.

powder charging system

Get Price Quote

The Vacuum transfer system is unique dry material transfer system for dust free and avoid to human touch. The vacuum transfer system is used in Pharmaceutical, Food, Agro Chemical, Sugar Industries and chemical. The system is use full for inline milling, sifting, blending, loading and unloading. The principle of vacuum transfer has been proven to be a better way to move many types of material and a giant step over manual handling. The technology exists for moving virtually any material that can be pulled through a hose or tube. The system is consisting of Blower, Vacuum receiver system with filter, cyclone filter and Pipe. The vacuum conveying systems designed specifically for the direct charge loading of blenders, mixers, sifter, milling, reactors or any vessel capable of withstanding a vacuum. The vacuum system can be provided mobile type with lifting provision to move one room to another room for loading and loading any machine.

Best Deals from Powder Charging System

powder charging system

Get Price Quote

Tool free maintenance - opening, cleaning and changing of screen does not require any tools and can be done in less than 5 minutes, Can be supplied with integral Powder Charging System, Also available with VFD for achieving desired particle size vs screen size, Capacities upto 1000 kghr depending on product bulk density and other properties

powder charging system

Get Price Quote

Powder Charging System is the lean-phased vacuum-conveying mode, which achieves material transfer by introducing the material into the moving stream of air at the desired rate. The PCS uses both vacuum and pressure to move powders and dispenses them with the help of gravity. It can charge powders from drums/ sacks to silos/ reactors at rates exceeding 4000 kg/hr and over 25 meters. . The system ensures the safe transfer of powdered material directly into mixing vessels or reactors, reducing dust generation and wastage as compared to manually charging powdered material through a manhole or a chute. The main purpose of having this contained system is to prevent operator exposure to the sensitive powders which may be hazardous to health and to minimize environmental exposure and cross-contamination to the product. Being operated on a vacuum principle the system is intrinsically dust free. The airflow is promoted by creating negative pressure throughout the system using the vacuum pump.

powder charging system

Get Price Quote

Pneumatic Automatic powder charging system is provided duly mounted on a swiveling davit interlocked with sensor to safeguard against blender. It is provided with a SS suction nozzle coupled to a flexible PVC food quality conveying pipe to enable for direct suction of the powder from container which will be discharged in blender and on complete charging of batch or maximum upto 70-80% by volume, filter bag of charging system may automatically be cleaned by auto reverse pulse jet mechanism thereby safeguarding against operator dependency, charging system may be swivelling on side and locked in that position which will actuate the sensor for that position, a dummy cover to be clamped on charging hole & homogeneous blending action can be initiated by starting the blender operation. After necessary blending period the material can be discharged & collected from bottom into container by manually opening the butterfly valve. The entire auto charging system is a tool free assembly.