Diesel Fired Powder Coating Oven

485,000 Per Piece

10 Piece (MOQ)

Gas Fired Powder Coating Oven

375,000 Per Piece

1 Piece (MOQ)

Best Deals from Powder Coating Machine Spare Parts

Aluminum Powder Coating Plant

805,000 Per Piece

1 Piece (MOQ)

powder coating powder manufacturing plant & machines

Get Price Quote

We at Clarion Enterprises An ISO 9001-2000 certified company by BSCIC-JAS-ANZ. We are the only company in India to produce Single screw Extruders (Buss swiss type) as well as Twin screw Extruders (AVP Type). We are manufacturing & exporters of Machines for Powder Coatings ( range 30 kg – 1800 kg hr). We are also manufacturing Special Purpose Machines (SPM) for various applications, mainly for automobile spares manufacturing firms. We have developed Single Screw Reciprocating Extruder (Kneader equivalent to Buss Kneader Swiss) & Twin Screw Extruder for Powder Coatings. We are also manufacturing the complete Plant for Manufacturing Powder Coatings it includes, ACM Pulvariser, Premixer, Vibro-Sievers, Double Cone Mixers, Compact Cooler Crusher (Kibbler), Containers, rack Storage System, for Automation of Plant on Turn Key basis also. In Addition we have developed & supplied Resin Manufacturing plant (Epoxy & Polyester Resin) along with technology transfer. Now we have started manufacturing the Powder Coatings Powders with quality product to improve the machine quality, reliability & spares life analysis. We are offering these services for powder coatings powder manufacturing on labor charges basis also, it will give a chance to new manufacturers to develop the market first & then start manufacturing at own. This facility can be offered to existing powder manufacturers also to cater the more orders. We are the only company in India which gives technology for Epoxy & polyester Resin Manufacturing technology. These resins are basic Raw materials for Powder Coatings Powders. Also we are manufacturers of plastic & rubber recycling machines – like extruder, aglo, plastic grinder etc. Also we are producing diesel fuel oil manufacturing plant from waste scrap plastic rubber capacity of 1.5-2 ton day, 3-5 ton day.

PTFE Coating Oven

Get Price Quote

Powder Coating Plants

Get Price Quote

Powder coating plants, Cathode Electro Deposition is most advanced and environment friendly Water based coating to be done on metal components. A combination of dip and spray ensures reach of paint at every corner of component having intrinsic shape as well. CED is chemically resistant, mechanically durable, and pleasant in appearance having very Good Salt Spray life and is sought for by all automobile users.

Electromechanical Reciprocator

Get Price Quote

Electromechanical Reciprocators is used for the smooth movement of the guns that are used for liquid paint or powder coating at stroke lengths and various speeds to suit conveyor & jig height respectively. At Hardwer Overseas Pvt Ltd you will get the best quality products at an affordable price. We are known as the best electromechanical reciprocator suppliers in India. Advantages • This can be easily adjusted and you can change the speed and length of stroke according to your needs. • Precise stroke and speed length. • Quality coating and increased production. • Exact stroke length adjustment reduces powder and paint wastage. • The adjustable chain tensioner helps to provide smooth running. • It needs less maintenance. Only lubrication and cleaning is required. • This reduces the labour cost. • You can control the smooth reversing electronically. Standard Features We are the best electromechanical reciprocating wholesale supplier in India. Our products have various features. Some are: • There is a dust protective cover for the parts that move • Online speed changing. • Swine type lockable castors for motion. Application And Uses • Painting: Used for the painting of automobile, industrial, domestic components and products of various sizes and shapes. • Powder Coating: This is used for the powder coating of domestic products and components, automobiles and industrial products as well. • Granulating: This is used for the granulating of pigments in pharmaceutical and chemical industries. Order our products online and get it delivered on time. We are the best Electromechanical Reciprocator Exporters from India.

Powder Dispensing Booth

171,000 - 360,000 Per Unit

1 Unit (MOQ)

Powder Coating Plant

700,000 Per ton

1 Unit (MOQ)

Powder Coating Plant

450,000 Per Piece

we are offering powder coating plant..

Powder Coating Booth

Get Price Quote

1 Piece (MOQ)

NST-DYG-135 Automatic Powder Lithium Ion Battery Coating Machine

1,000,000 - 2,000,000 Per Set

1 Piece (MOQ)

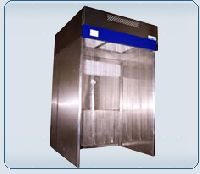

Sample Dispensing Booth

148,000 Per Piece

1 Piece (MOQ)

Sampling Booth has been designed to provide a Class 100 working environment at rest, with built-in scavenging system to ensure protection for the product, operator and surrounding environment. The system comprises: Imported Minipleat HEPA Filter with hot melt technology, which conforms to EU 13 Grade, with an efficiency rating better than 99.99% for 0.3μ at supply position Imported Minipleat HEPA Filter with hot melt technology, which conforms to EU 13 Grade, with an efficiency rating better than 99.99% for 0.3μ at exhaust position Fabtech make prefilter which conforms to EU 4 Grade, with efficiency of 90% down to 10µ. These Filters are basically made from micro-fibre-glass media and are inherently washable Fabtech make Intermediate filter which conforms to EU 7 Grade, with efficiency of 95% down to 3µ. These Filters are basically made from micro-fibre-glass media and are inherently washable Motor Blower provided are statically and dynamically balanced, Supply of sufficient capacity and static pressure is used to take care of airflow requirement for entire life of HEPA. The blower is high-performance, noise abated, light weighted statically and dynamically balanced SS 304 Double Walled Side Panels Mechanical Differential Pressure Gauge (0mm-25mm: 2 Nos.) to monitor pressure drop across intermediate filter Photohelic Differential Pressure Gauge HEPA filter and (0mm-10mm: 1 No.) To monitor pressure drop across PRE Filter with respect to ambient Electrical control panel mounted on the side panel of the unit Tube Light ON/OFF Switches for motor 5/15 Amp single-phase switch socket for external equipment DOP Test port at upstream of HEPA filter

Powder Coated Oven

Get Price Quote

We have segregated our infrastructural facility into different units and one of them in warehouse wherein we keep a huge lot in safe and secured manner. We are associated with a team of quality analysts who hold years of experience in this domain and conduct strict quality checks for ensure high quality of raw material as well as finished products.

Conveyorised Powder Coating Plant

1,500,000 - 15,000,000 Per Piece

We are the leading Conveyorised Powder Coating Plant manufacturer that is suitable for powder coating of high volume components. Conveyorised Powder Coating Plant is available in large sizes and has the capacity to accommodate more than two painters and automatic painting guns. Besides, we offer these in various tailored specifications as per the needs of the clients. Features Robust infrastructure High efficiency Easy operation Highly durable Low maintenance Cost effective Applications Powder Coating Powder Painting

Powder Coating Powder

150 - 250 Per Kilogram

10 kg (MOQ)

We would like to introduce our company as the leading manufacturer, exporter and supplier of the best quality range of Epoxy-polyester and Pure Polyester Coating Powder in all Finishes like Glossy, Matt , Structure , Texture, Semi Glossy , Satin , Metallic, antique etc.

Industrial Powder Coating Oven

50,000 - 6,000,000 Per Piece

1 Piece (MOQ)

UK Surface Coating is the best industrial powder coating oven manufacturer. Our company has manufactured an industrial oven to create powder coating for all modern industries. The oven is accessible in numerous standard sizes (custom sizes are provided as per customer request) and has the perfect solutions for powder curing applications. A powder coating oven includes a combined wind current arrangement. It delivers a uniform distribution of air along the whole length of the work chamber, thus delivering optimum curing cycles besides quality cured finishes The oven that we have come up with is intended to avert the blowing off of powder and saves the hassle of reworking by saving both money and time. The finishing industry is very demanding as it depends intensely on powder-coating broilers with high productivity. Choose us and get our products as we are the best industrial powder coating oven suppliers.

Powder Coating Oven

Get Price Quote

Sample Dispensing Booth

Get Price Quote

1 Piece (MOQ)