Powder Compacting Presses

Get Price Quote

Powder compacting presses is the result of constant R & D, backed by more than two decades of experience in Electro-hydraulics. The experience we've obtained as well as our customers input has been the basis for the improvement we do in our hydraulic presses.

powder compacting press

Get Price Quote

Offers powder compacting press. wide ranges of powder compacting presses are manufactured from heavy steel plates. The min. Frame is fabricated from plates & thereafter they are stress relieved. The presses are designed in such a way that we get negligible deflection during its working. Application: these are generally used to compact mixture of powders such as cobalt,iron,copper,tin,silver,tungsten metal carbide etc. Including diamond grit in dies through down stroke plunger. It could be multiple die system or single die for compacting operation to get segmentwire saw to be hot sintered thereafter.

Best Deals from Powder Compacting Press

powder compacting press

Get Price Quote

1 Piece (MOQ)

Cold Compaction Press

Get Price Quote

We are offering cold compaction press.hydraulic cold press in frame structure model: cp-150t · platen size : 500 x 500 mm. · cold pressing area : 30 sq. Cm. · powder filling : manual in steel moulds. · maximum day-light : 200 mm. · main cylinder size : 10” cyl x 7” ram x 4” stroke. · maximum tonnage : 100 tons. · clamp cylinder : 4” dia x 5” stroke, 2 nos, 25 tons (e). · hydraulic motor : 7.5 hp., 1500 rpm. · over-all dimension : 1200(w) x 1400(d) x 1800(h). · weight of the machine : approx. 2200 kgs.

compacting press

Get Price Quote

Electropneumatics designs and builds tailor-made powder compacting and sintering presses for near-net shape forming of parts. Powders of iron, steel, high speed steel, carbides, ceramics, friction material, bronze, copper and their alloys can be formed into complex parts of high strength. Our presses can be used for dry and wet compacting and come with a wide variety of options, sophistication and automation for large volume, continuous production. These are hydraulic high-efficiency automatic presses that can be supplied with sophisticated precise tools and tool adaptors to ensure production of complex parts to high quality levels. Sintering and sizing presses are also available.

Compacting Hydraulic Press

Get Price Quote

powder compacting press

1,000,000 Per Piece

1 Piece(s) (MOQ)

powder compacting press

Get Price Quote

Volumetric Cold Compacting Press

Get Price Quote

Latest trend to increase the output production rate with automation made us to manufacture the volumetric cold compacting press . Hopper is filled with granulated powder with diamond grit of the required proportion . Initiation of cycle put hydraulicpnuematic cyclinder ,fill the powder in the cavity (diespunch as per customer's need) followed up by pressing by top cylinder position ,ejector lifts up the cold compacted segment. This is automatically pushed into the tray provided , simultaneously filling the cavity with new powder and auto cycle continues. Change of diespunch is very easy and doesnot take more than 20 minutes these process are manufactured into 2 different standard models of 5 tonnes & 12 tonnes with following specifciations.

Double Compacting Hydraulic Presses

Get Price Quote

We offer a wide collection of H Frame Hydraulic Presses, which are known for their rigid and sturdy steel welded construction for nominal frame deflection. Our product has a compact design along with an inbuilt hydraulic power pack, which provides it superior productivity. It can be operated using most advanced electronic control (PLC). This product is widely used in molding, bending, drawing, straightening, punching, riveting, assembling and other purposes. Other highlighting features of our product are economic prices, easy installation and high speed operation.

Hydraulic Compact Bale Press

Get Price Quote

TECHNICAL SPECIFICATION Capacity : 25 Ton Bale size (L x W x B) : 1220 mm x 910 mm Body : Fabricated (Four Side Open) Electric motor : 5 H.P 3 Phase 1440 RPM Hydraulic pressure : 2320 Psi (160 Bar)

Powder Compacting Hydraulic Press

Get Price Quote

We are offering powder compacting hydraulic press. we have a used powder compacting hydraulic presses with following specifications : capacity : 250 ton make electro pneumatic upper ram stroke : 350 mm upper ram tonnage : 250 ton upper ram movement monitored by mitu toyo linear scale upper ram movement control by servo valveupper ram movement fast approach and dressing is controlled by plc lower ram stroke : 200 mm withdrawal tonnage : 175 ton prefill 0 to 15 mm die float 0 to 50 mm lower ram movement monitored by mitu toyo linear scale lower ram movement controlled by servo valve feeder stroke 200 mm feeder movement controlled by hydraulic cylinder pressing programs are fed in plc and stored hydraulic power pack rexroth make good working condition.

Waste Compaction Presses

Get Price Quote

We are offering waste compaction presses. Manufacturing program: presses for toxic materials used containers hotel waste hospital waste according to user's individual requirements. Press for compaction of toxic chemicals before disposal.

Powder Compacting Presses

Get Price Quote

The Powder Compacting Presses come in two versions with single and double action types. Adjustable Tonnage of compaction can be provided from both Top & Bottom. By using position & pressure sensors like Linear Potentiometers & Pressure Transmitters, the rate of compaction can be continuously varied as per the requirement. By the use of proportional hydraulics the hydraulic presses required and oil heating is minimised where duration of compaction is high.

mechanical powder compacting press

3,000,000 Per Set

1 Set(s) (MOQ)

powder compacting press

Get Price Quote

powder press is fit for application in powder metallurgy, magnetic materials, hard alloys, fine ceramics and other industries, where powders are required to be pressed to make specific shapes, particularly the press for making items of complicated shapes.The structure of welded steel plates ensure high strength for the machine body, ensuring steady toughness, high rigidity and high precision and ensuring the quality of processed items in long-time operation. Cam-crank guide is adopted to ensure long-time pressing and air removal in the process of powder pressing.Pneumatic friction clutch is adopted to ensure machine stopping at any position.Die carrier is adopted to make the dies be replaced and adjusted conveniently.

Compact C Frame Presses

Get Price Quote

Compact C-Frame presses are specially designed for small components requiring limited spaces. This not only reduces the initial investment but also the space requirement of the machine thus making small manufacturing cell possible. These compact and low cost c-frame presses are ideally suited for small size jobs such as automotive cable crimping, hose pipe end fitting crimping, stamping etc.

Compact iron scrap baling press

Get Price Quote

Compact iron scrap baling press manufacturer in Coimbatore, Tamilnadu, India. Our valued clients can avail from us a significant range of Compact Iron Scrap Baling Press. These offered products are fabricated by making use of supreme quality required basic material and components, these offered products ensure longer service life, resistance against corrosion and compressive strength. Furthermore, our clients can avail the offered products in different specification as per their requirement. Products that we offer are manually operated using two control valves and are provided with single compact unit, placed over the channel with manual front door operation.

Powder Compacting Presses

Get Price Quote

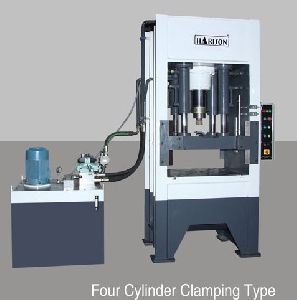

Four Pillar Powder Compacting Press Presses from 63 KN. to 2000 KN. capacity and straightening attachment for bar length 100 mm to 5000 mm can be supplied.Efficient hydraulic system for hydraulic power generationusing latest power generation using latest logic controlproportional values we manufacture presses of manually operated type,electrical push button operated type , PLCPC based programmable type.

Hydraulic Powder Compacting Presses

Get Price Quote

We offer ydraulic powder compacting presses. Electropneumatics designs and builds tailor-made powder compacting and sintering presses for near-net shape forming of parts. Powders of iron, steel, high speed steel, carbides, ceramics, friction material, bronze, copper and their alloys can be formed into complex parts of high strength. Our presses can be used for dry and wet compacting and come with a wide variety of options, sophistication and automation for large volume, continuous production. These are hydraulic high-efficiency automatic presses that can be supplied with sophisticated precise tools and tool adaptors to ensure production of complex parts to high quality levels. Sintering and sizing presses are also available. features 1. Sturdy press frames, specifically design for long daylights and minimum deflection, in h-frame, ring frame, 4-pillar and 4-column constructions 2. Top, bottom and auxiliary ejection systems, as per requirement 3. High speed, high production models available 4. Incorporated with all safety features and diagnostic controls optional features are 1. Auto ejection system for specialised requirements 2. Mechanical knock-outs 3. Shock absorbers 4. Quick die change systems 5. Pick and place part transfer units 6. Automatic weighing arrangement 7. Staticfloating dies 8. Magnetisingdemagnetising unit 9. Filter-cloth slurry cleaning arrangement 10.supply of tool adaptors 11. Electropneumatics’ intelligent, user-friendly interface and plccnc controls for real-time programming and monitoring of all process parameters