Pre Engineered Building Shed

1,000 - 2,000 Per Square Feet

5000 Square Feet (MOQ)

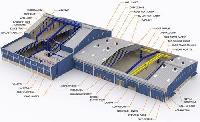

a pre-engineered building is a system utilizing three distinct product categories: built-up “i” to shape primary structural framing members (columns and rafters) cold-formed “z” and “c” to shape secondary structural members (roof purlins, wall girts, and eave struts)

Steel Pre Engineered Building Shed

275 - 350 Per Square Feet

20000 Square Feet (MOQ)

Best Deals from Pre Engineered Building Sheds

Pre Engineered Building Systems

Get Price Quote

Pre Engineered Buildings (PEB) are the buildings which are engineered at a factory and assembled at site. Usually PEBs are steel structures. Built-up sections are fabricated at the factory to exact size, transported to site and assembled there with bolted connections. This type of Structural Concept is generally used to build Industrial Buildings; like –Railway / Metro Stations, Warehouses etc. The adoptability of PEB in place of Conventional Steel Building design concept resulted in many advantages, including economy & easier fabrication. These building structures can be finished internally to serve any functions i.e., actually help in low rise building design. Examples of PEB Buildings are warehouses, Canopies, Factories, Bridges etc. Components of PEB : Pre Engineered Buildings consist different steel structural members which are: Primary Frames Secondary Structural Elements: Cold Formed Members, which can be in different shapes like “Z”, “C” etc. In general known as “Purlins”. Roof & Wall Panels : Tin shades & Curtain Wall made of Glass & Roll-formed steel sheets usually comes in this category Sandwich Panels: Sandwich Panel is made of three layers, in which a non-Aluminum Core is inserted between two aluminum sheets. Other Accessories: Bolts, Insulation, etc. Advantages of PEB : There are many advantages of Pre Engineered Buildings, which are as follows, Quality control is the main advantage as all the structural member are engineered beforehand, standards of different codes also taken into consideration & these components are made in factory under the supervision of Quality Control Engineer. Lower cost due to the saving in design, manufacturing and on site erection cost. Minimizing time of construction due to the use of software for design of the structural components. Low Maintenance due to use of standard quality of paints over steel members , which increases the ability to withstand & finally the maintenance cost will be low as compare to conventional steel building. Quick Erection, as all the members are Pre Manufactured & skilled labor is used for connections of different components. Warranty on PEB, mostly warranty period of 20 years given by manufactures for PEB. Disadvantages of PEB : Although PEB have many advantages in the field of Industrial structure but still there are some demerits of Pre Engineered Buildings, which are as follows, Rusting / Corrosion Sensitive, as if the quality of steel used or paint used for coating of steel members is not of good quality , then it can damage the structure and thus reduces the life of structure. Insulation Cost, as insulating the building to an agreeable benchmark will furthermore add to your construction costs. Appearance, Steel Sections can be unattractive when left exposed.

Pre Engineered Building Industrial Shed

Get Price Quote

Pre Engineered Building Sheds

250 - 800 Per Square Feet

5000 Square Feet (MOQ)

introduction vistar is specialized in design, manufacturing and installation services of pre-engineered buildings and structural steel projects. the foundation of the company has been laid by professionals having rich experiences in business development, project management, project execution and customer relationship. the necessity to meet the growing demand of pre-engineered buildings in india and to provide complete end to end solution to clients for their buildings requirements has been the main reason for emergence of vistar. our aim is not merely supply the buildings to customers but to put in use our expertise at each and every stage of project right from the initial stage i.e. concept and planning, designing, detailing, manufacturing and execution of projects to provide customer an economical and a superfast solution for his requirement. complete solution vistar does far more than supply and erection of pre engineered metal buildings. we offers complete solutions to the customer enabling them to focus on their organization strategic goals. we undertake a single source responsibility for the project through co-ordination of all the departments viz design & engineering manufacturing project management logistics erection pre-engineered building is a combination of built-up primary members, secondary members and roofing and wall cladding either single skin or insulated panels. built-up members and secondary members form a well braced steel skeleton structure which is enveloped by roofing and wall cladding. thus, we get an air tight, weather proof, energy efficient building to serve the need of customer. pre-engineered buildings are designed with the help of international standards. these are precisely manufactured as per customer’s requirement and also can be fitted with different structural accessories including mezzanines, canopies, fascia, partitions, crane beams etc. to enhance the building usage and its aesthetics. advantage of pre engineered building superfast construction in comparison to conventional construction methods. cost effective and economical building solution. column less large clear spans can be easily achieved with effective costing. pre-engineered building offers great flexibility in terms of future expansions and modifications. due to manufacturing under factory controlled environment, highest quality standards are maintained. long durability and low maintenance cost. pre-engineered building construction is green building construct ion due to recyclable properties of steel. hassle free construction for client due to single source responsibility of pre-engineered building supplier. accessories ridge vent turbo ventilator trims & flashings sky light wall light wall opening fasteners canopy fascia insulation

Pre Engineered Building Sheds

Get Price Quote

1. raj roofing company peb – pre engineering building pre-engineered metal building under construction in structural engineering, a pre-engineered building (peb) is designed by a peb supplier or peb manufacturer, to be fabricated using best suited inventory of raw materials available from all sources and manufacturing methods that can efficiently satisfy a wide range of structural and aesthetic design requirements. within some geographic industry sectors these buildings are also called pre-engineered metal buildings (pemb) or, as is becoming increasingly common due to the reduced amount of pre-engineering involved in custom computer-aided designs, simply engineered metal buildings (emb). historically, the primary framing structure of a pre-engineered building is an assembly of i-shaped members, often referred as i-beams. in pre-engineered buildings, the i beams used are usually formed by welding together steel plates to form the i section. the i beams are then field-assembled (e.g. bolted connections) to form the entire frame of the pre-engineered building. some manufacturers taper the framing members (varying in web depth) according to the local loading effects. larger plate dimensions are used in areas of higher load effects.

Pre Engineered Building Sheds

Get Price Quote

We are offering pre engineered building sheds. Peb structures: - an increasing number of consumers are now opting for pre-engineered building systems because of the significant advantage they offer in terms of time and convenience. We provide turnkey peb solutions-right from the structural design stage, till the actual installation. easy to assemble, low on maintenance, extremely strong, weather-resistant and secure. We cater to every manufacturing component of the pre-engineered buildings sector, be it in terms of roofing, insulation, structural steel constructs, or ventilation.

Pre Engineered Building Sheds

Get Price Quote

Pre Engineered Building Sheds

Get Price Quote

we offer a widest range of frp raw materials, frp products, frp dayight sheets, pre-engineered buildings, wind operated turbo ventilators,etc..

Pre-Engineering Building Shed

Get Price Quote

We undertake online payment procedures which are completely safe and hassle free. The online transactions are supported by advanced security features. We are most sought after Supplier, affianced in providing user and pocket friendly Pre-Engineering Building Shed.

Pre Engineered Spinning Mill Shed

250 - 350 Per Square Feet

100 Square Feet (MOQ)

PEB spinning and ginning sheds are facilities where raw cotton is processed into a usable fiber. The process begins with PEB spinning, which involves separating the seeds from the cotton fibers. This is done using a machine called a cotton gin, which separates the fibers from the seeds by pulling them through a series of wire screens and saw-toothed disks. Once the seeds have been removed, the cotton fibers are cleaned and prepared for spinning. This is done using a variety of machines, such as carding machines and drawing frames, which comb and straighten the fibers. The fibers are then spun into yarn, which is used to make a variety of products, including clothing, bedding, and towels. Ginning sheds are typically large, industrial facilities that are equipped with a range of machines and equipment to process raw cotton into usable fiber. They are an important part of the global textile industry, as cotton is a widely used natural fiber that is prized for its strength, durability, and comfort. As a trusted leader in the field of Pre-Engineered Building (PEB) construction and manufacturing, we are dedicated to providing tailored solutions for your spinning and ginning needs. Why Choose Blueladder EPC Solutions for PEB Spinning & Ginning Sheds? 1. Expertise in PEB Construction:At Blueladder EPC, we bring decades of experience to the table. Our skilled engineers and architects specialize in PEB construction, ensuring that your spinning and ginning sheds are built to perfection. We understand the unique requirements of the textile industry and tailor our designs accordingly. 2.Customized Solution: We recognize that every project is different. That’s why we offer fully customized PEB spinning and ginning shed solutions. Our team will work closely with you to understand your specific needs, ensuring that your facility is optimized for maximum productivity. 3. Quality Materials & Construction: Quality is at the heart of everything we do. Blueladder EPC uses only the finest materials and cutting-edge construction techniques, guaranteeing the longevity and durability of your spinning and ginning sheds. Our commitment to excellence is evident in every project we undertake. 4.Timely Project Delivery: Time is of the essence in the textile industry. Our streamlined construction processes and project management expertise ensure that your PEB spinning and ginning sheds are completed on schedule. We prioritize your operational timelines and minimize disruptions. Our Process Consultation: We begin by thoroughly understanding your spinning and ginning shed requirements. Our experts will work closely with you to gather all necessary information. Design & Planning: Our team of architects and engineers will create a customized design that optimizes space, functionality, and efficiency. Material Procurement: We source high-quality materials and components for your project, ensuring that everything meets our rigorous quality standards. Construction: Our skilled workforce will construct your PEB spinning and ginning shed with precision and attention to detail. Quality Assurance: Before handing over the facility, we conduct rigorous quality checks to ensure it meets our strict standards. On-Time Delivery: We pride ourselves on delivering projects on time, ensuring minimal disruption to your operations. Contact Blueladder EPC Today When it comes to PEB spinning and ginning sheds, Blueladder EPC is your trusted partner. Our commitment to quality & customization sets us apart. Contact us today to discuss your project and discover how we can help you achieve your goals. Your success is our priority.

Pre Engineering Building Sheds

210 Per Square Feet

pre engineering building industrial factory shed

Get Price Quote

Ganesh engineering an ISO 9001:2008,SPECIALIZES IN MANUFACTURE,SUPPLY AND ERRECTIONB OF peb .ganesh pre engineered buildings are custom designed to meet exact requirements using steel structures,plate welded H/I beams,profiled sheets,z nad c sections,steel decking sheets,single skin and insulated sandwitch panels and other building accessories such as flashing,gutters,ridges,doors,windows and louvers

Pre Engineered Building Shed

250 - 350 Per Square Feet

Pre Engineered Building Sheds

Get Price Quote

EPACK Prefab No1.Prefabricated Structures & PEB Buildings Manufacturer in India. Get Prefab Structures like Prefab Schools, Hospitals, Resorts, Factory Sheds etc. We deals in Turnkey Projects.

Pre Engineered Building Sheds

110 - 170 Per Square Feet

Pre Engineered Building Sheds

Get Price Quote

25000 Square Meter (MOQ)

Pre engineered building shed for - 1. Industries 2. Warehouses 3. Commcercial 4. Pre Fabricated Houses etc.

Pre Engineered Building Sheds

Get Price Quote

Pre Engineered Building Sheds

Get Price Quote

We are the leading manufacturers, exporters and supplier of this products.

Pre Engineered Building Sheds

160 Per Square Feet

Pre engineered building sheds providing customized solution as per customer's need since more than 2 decades (since1995) for any details related to steel buildings, stadiums, bridges, fob metal buildings, hospitals,warehouses, coldstorage, industrial sheds, shopping malls, universities, educational institute's buildings, metal structures, peb structure, colour coated sheets, shed etc. #mechfab #since1995 #qualityproducts #since22years #completebuildingsolution #peb #toppebmanufacturer #metalbuildings #steelbuildings #shed #warehouse #coldstorage #preengineeredbuilding #shoppingmalls #steelbridges #fob #industrialshed #stadium