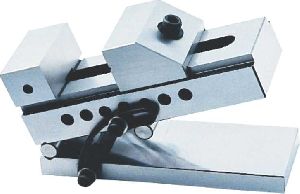

Sine Vice Pin Type Griding Vices

Get Price Quote

Fabricated with high quality En31 alloy steel body, our Precision Sine Vices are widely appreciated for their extensive usage. In order to provide them with high strength, vice hardened to 54-56 HRC. Further, to enhance the job tilting and lifting of elements, the movable jaw pushes the job at 45 degree to maximize the clamping force. Further, these vices are provided with end pockets for convenient clamping and are supplied with side support to hold the object. Features: En31 alloy steel body and jaw hardened to 55-60 HRC. Movable jaw pushes the job at45degree therefore, ensure maximum clamping force thus elements job tilting and lifting. End pockets for convenient clamping. Supplied with side support to work as a job locater for repeat operation.

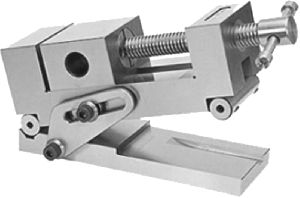

Pin Type Precision Sine Vice

Get Price Quote

We are among the reckoned manufacturers and suppliers of an exquisite collection of precision sine vice - pin type. These products are manufactured with the finest quality basic raw material, in strict adherence with the international quality norms. Our catered products are extensively used on milling and grinding machines and are appreciated due to their reliability and durability. Due to their usage in multiple applications, we offer these products according to the demands of our valued customers. Specifications: hardened & tempered to 52 -56 hrc angle setting accuracy within ± 5 seconds. All side parallelism and squareness within ± 0.015 mm. Center distance of rollers within ±0.005 mm. A recess of exactly 2mm depth is provided on rest plate for setting up of very small angles with standard gauge blocks.

Best Deals from Precision Sine Vice

Precision Sine Tool Vice

Get Price Quote

Made By : Goldsmith Model No. : PSTVP PRODUCT FETURES Precision Sine Tool Vice ( Pin Type ) Series PSTVP The precision tool vices • Made of high – quality tool steel. Hardened & precision ground, parallelism ± 0.005mm / 100mm, squareness ± 0.005mm Hardness HRC 58 – 62. • Precision sine vice is used to obtain accurate angle by t he use of slip gauge, Apart from its use on milling & grinding machine this since vice can also be used as a reference for inspection purpose

Precision Sine Vice

13,500 Per Piece

Precision Sine Vice

Get Price Quote

Precision Sine Vice, Friction Welding Machine, Bar peeling machine

Precision Sine Vice

Get Price Quote

Precision Sine Vice is used to obtain precise angles by means of gauge blocks. Apart from its use on milling and grinding machine, the sine Vice can also be used as a reference for inspection. All Hardened & Tempered to 52-56 HRC. All side Parallelism & Squareness within 0.005mm Centre distance of rollers within 0-005mm Inspection certificate is furnished

PRECISION COMPOUND SINE VICE - SCREW TYPE

Get Price Quote

'TOOLFAST' Precision compound Sine Vice has compound sine angle setting on two sine plates. Both the tiltings are controlled by fine screws.>> All Hardened & Tempered to 52 - 56 HRC.>> All side Parallelism & Squareness within ± 0.005mm.>> Centre distance of rollers within ± 0.005mm.>> Inspection certificate is furnished. Chart for setting sine angles with the help of gauge blocks is provided.

Precision Sine Vice

Get Price Quote

Precision Sine Vice

8,000 Per Piece

PRECISION TOOL MAKERS SINE VICE

Get Price Quote

* Manufacturing from special alloy steel, these solid sine vices are fully hardened (55 to 60 HRC) and tempered, mounted on to a precision hinges bottom plate.* All Surface of the vice are precissional ground for maximum accuracy* These are very useful for manufacturing processes that require the highest standards of clamping accuracy at desired angles.* Very small angles to be set with easy using standard gauge blocks.

Precision Sine Vice

11,200 Per Piece

Precision Sine Vice

Get Price Quote

Features - Manufacturing from special alloy steel,these solid sine vices are fully hardened (55-60 HRC) and tempered,mounted on to a precision hinges bottom plate. - All surfaces of the vice are precessional ground for maximum accuracy. - These are very useful for manufacturing processes that require the highest standards of clamping accuracy at desired angles. - Very small angles to be set with ease using standard gauge blocks.

Precision Sine Vice

Get Price Quote

Precision sine vice in manufacturing a wide range of Milling Machine Vice, which is in wide demand across the country. These precision-engineered machines are manufactured using graded casting and offer excellent performance for a longer period of time.

Precision Sine Vice

Get Price Quote

Manufactured from selected tool steel, these Solid Sine Vices are fully hardened (55-60 HRC) and tempered, mounted onto a precision hinged bottom plate. All the surfaces of the vice are precisely ground for extreme accuracy These are very useful for manufacturing processes that require the highest standards of clamping accuracy at desired angles A minute angle step of 0.2"5 mm allows very small angles to be set with ease using standard gauge blocks

Precision Sine Vice

Get Price Quote

Banking on our enriched industry experience, we are engaged in offering a huge gamut of precision sine vice. This high grade precision sine vice is designed and fabricated using high grade metals that are procured from reliable vendors of the market. Our wide range of precision sine vice is fabricated under strict supervision of quality controllers to offer the best quality products.

Precision Sine Vice

Get Price Quote

Manufactured form Selcted Tool Steel. Hardness 55-60HRc. Used for Precision measurement. Setting of angles. Right angle grinding & light machining. Accuracy for Squareness.Flatness & Parallelism is 0.005mm

Precision Sine Vice

Get Price Quote

Used for Precision measurement, setting of angles, Right angle grinding & light machining. Made from high quality alloy steel. Accuracy for Flatness, Squareness & parallelism within 0.005mm. Angular accuracy within + 5 seconds. Centre distance between rollers is within +0.005mm.

Precision Sine Vice

Get Price Quote

Precision Sine Vice is used to obtain precise angles by means of gauge blocks. Precision Sine Vice is mounted with precision Hinged hardened & ground rollers on hardened bottom plate made of tool steel. This Precision Sine Vice can be used as a reference for inspection. We provide a chart for setting sine angles with the help of gauge blocks. Features Hardened & tempered to 52 - 56 HRC.Angle setting accuracy within + 5 secondsAll side parallelism & Squareness within + 0.005 mmCentre distance of rollers within + 0.005 mm.A recess of exactly 2 mm depth is provided on rest plate for setting up of very small angles with standard gauage blocksRust free hardened & ground hinge rollerInspection certificate is furnished

Precision Sine Vice

Get Price Quote

Precision Sine Vice

16,000 Per Piece

1 Piece (MOQ)