pressure controllers

1,000 - 10,000 Per Piece

10 Piece (MOQ)

Pressure controllers are electronic devices that automatically regulate pressure in a system. They function by using a pressure sensor to monitor the current pressure, comparing it to a set point, and then activating control mechanisms to maintain the desired pressure level. Here's a breakdown of their typical specifications: General Specifications · Pressure Range: The range of pressure the controller can regulate (similar to pressure transmitters, ranging from fractions of psi to thousands of psi). · Control Output: This specifies how the controller influences pressure. Common outputs include: o Analog Outputs (e.g., 4-20mA current loop, 0-10V voltage) to control variable speed drives, solenoid valves, etc. o Digital Outputs (e.g., on/off relays) to activate pumps, compressors, or alarms. · Set Point: The desired pressure level the controller will maintain. Performance Specifications · Accuracy: Expressed as a percentage of full scale (%FS) for both the pressure sensor and the control mechanism. Typical accuracy is around ±0.25%FS to ±1%FS. · Proportional Band (Deadband): The range around the set point where the controller won't activate any control actions. A narrower band provides tighter control but can lead to more frequent cycling. · Reset: The amount of time it takes for the controller output to reach its maximum or minimum value after a change in the measured pressure. · Response Time: The time it takes for the controller to react to a pressure deviation from the set point (usually in milliseconds). Additional Features · Control Algorithm: Different algorithms are used for pressure control, each with its own advantages. Common types include: o Proportional-Integral-Derivative (PID) control: Offers precise control but requires careful tuning. o ON/OFF control: Simpler but can lead to pressure fluctuations. · Display: Many controllers have a digital display showing the measured pressure, set point, and control output. · Alarms: Some models can trigger alarms for high or low-pressure conditions. · Communication Protocols (Optional): Advanced controllers may offer communication protocols (e.g., Modbus, HART) for remote monitoring and configuration. · Power Supply: The voltage required to power the controller (typically 24VDC). Factors to Consider When Selecting a Pressure Controller · Pressure Range: Ensure the controller's range covers the desired pressure regulation range in your application. · Control Output: Choose a controller with an output compatible with your control valves, pumps, or other actuators. · Control Algorithm: Select an algorithm (PID, ON/OFF, etc.) that best suits your application's pressure control requirements. · Accuracy: Consider the required accuracy level for your process. · Additional Features: Choose features like alarms, communication protocols, or a display based on your needs. By understanding these specifications and factors, you can select a pressure controller that effectively regulates pressure within your system and aligns with your application's specific requirements.

DH Digihelic Differential Pressure Controller

Get Price Quote

dh digihelic differential pressure controller the series dh digihelic® differential pressure controller is a 3 in 1 instrument possessing a digital display gage, control relay switches, and a transmitter with current output. Combining these 3 features allows the reduction of several instruments with one product, saving inventory, installation time and money. The digihelic® controller is the ideal instrument for pressure, velocity and flow applications, achieving a 0.5% full scale accuracy on ranges from 0.25 to 100 in. W.c. the digihelic® controller allows the selection of pressure, velocity or volumetric flow operation in several commonly used engineering units. Two spdt control relays with adjustable dead bands are provided along with a scalable 4-20 ma process output. In velocity of flow modes, a square root output is provided on the 4-20 ma signal to coincide with the actual flow curve. The series dh provides extreme flexibility in power usage by allowing 120220 vac and also 24 vdc power which is often used in control panels. programming is easy using the menu key to access 5 simplified menus which provide access to: security level; selection of pressure, velocity or flow operation; selection of engineering units; k-factor for use with flow sensors; rectangular or circular duct for inputting area in flow applications; set point control or set point and alarm operation; alarm operation as a high, low or highlow alarm; automatic or manual alarm reset; alarm delay; view peak and valley process readings; digital damping for smoothing erratic process applications; scaling the 4-20 ma process output to fit your application's range; modbus® communications; and field calibration. with all this packed into one product it is easy to see why the digihelic® controller is the only instrument you will need for all your pressure applications.

Best Deals from Pressure Controllers

Melt Pressure Controllers

Get Price Quote

Ideal for synthetic fibre, photographic films, etc., our another variety, that we deal in, is Melt Pressure Controllers. We are tagged as a prime Manufacturer, Exporter and Supplier of Melt Pressure Controllers based in Delhi, India. The offered product is made from the finest quality material and used to display pressure, temperature, etc. Offered at economical prices, our Melt Pressure Controllers have long lifespan and compact in size. Details : Display pressure, temperature Optional second input/output for cost-effective single instrument View display information locally or remotely by optional Modbus RTU Bar graph display for quick-glance scaled value Two alarm relay output, third alarm optional Analog retransmission of process variable allows signal to be sent to other devices Configure locally or remotely by optional Modbus RTU Digital security code prevents unauthorized use IP65/NEMA 4X rated for harsh environments Ideal For : Synthetic Fibres Photographic film Plastics - Solid extrusion Wire coating Multi-layer extrusion Extrusion Melt Pressure Controllers : Melt pressure control Suitable for 4 or 6 wire transducers Pre-screen pressure monitor and alarm Pressure alarms Simple calibration Fieldbus communication options The Controllers are fully programmable melt pressure controller, suitable for precision pressure control in the plastic extrusion industries. In its basic format the Controller standard hardware includes an input for melt pressure measurement, an analog output to drive the extruder screw and alarms to detect high and low pressure conditions. Additionally, a second pressure input can be connected providing the facility to put a differential pressure alarm across the screen. Automatic transducer calibration procedures and 5Vdc or 10Vdc transducer power supplies are provided for both inputs

Pressure Control for Pump

3,500 Per piece

1 Piece (MOQ)

Specification/Additional Details Usage/ApplicationPressure Control for pump Voltage220 V AC

Aerosense Differential Pressure Controller

Get Price Quote

Aerosense differential pressure controller it is recommended that industrialists dealing in the domain of pressure control & temperature drift should make the selection of the all new range of aerosense differential pressure controller. The device is a type of differential pressure indicator that comes with advanced & standard accessory items. It is also enabled with the zero point adjustment facility and high point adjustment (span) that is provided to deliver the excellent results as per the desired levels of quality in hvac, fan & blower industries. Features: better accuracy highest pressure range protection standard conformance

Pressure Controller

Get Price Quote

The Pressure Controllers, we make available, are used in oil, sugar and chemical industries. We procure the Pressure Controllers from well-known sources that resort good production practices. We are capable of handling medium as well as bulk orders of buyers as we have maintained a huge stock of Pressure Controllers in our spacious warehouse. Besides, we quote nominal prices. From Maharashtra (India), we are the renowned Exporter and Supplier of Pressure Controller. Features : Controller can be changed from Direct to Reverse action or vice-versa by simple repositioning nozzle block and reversing Bellow connections. Universal case-mounting provide with the controller helps the mounting to be done on valve panel or on the yoke of a Control Valve. The case is weather-poof and even suitable for field installations. Applications : Oil, Chemical and Sugar Industry.

ShearTrac II Volume Pressure Controller

Get Price Quote

ShearTrac-II operates as an intelligent loading system. It uses feedback from transducers to provide real-time control of the load frame. Two force transducers (horizontal and vertical) and two displacement transducers (horizontal and vertical) are the sensors for the ShearTrac-II unit. The computer loads or unloads the load frame until the readings from the transducers equal the values required to meet the test specifications. The loading mechanism to apply normal loads is raised and lowered by a micro-stepper motor connected to a worm gear. The loading mechanism to apply shear loads is moved left and right by a second combination of micro-stepper motor and worm gear. Limit switches for both horizontal and vertical motions prevent running the loading mechanism beyond its physical limits. The standard ShearTrac-II unit uses a 16-bit AD card. This means that the raw data reading units are on an integer scale from 0 to 65536 (0 to 216). Each reading unit is also called a count. These count readings must be converted to engineering units. The system is supplied with calibration factors that do this conversion. The system uses calibration data to relate count readings to engineering units. Because ShearTrac-II is an intelligent loading system, all components must be functioning correctly for the system to operate. All operation of the load frame must occur through the computer for full automation. Separate manual operation is possible through front panel keypads. To avoid damage to any component, readings from all sensors are checked by the computer hundreds of times per second. Any analog or digital reading outside the acceptable condition prevents the micro-stepper motors from running.

Pressure Controller for Heavy Presses

Get Price Quote

PRC has designed & developed a complete solution for heavy presses (Pneumatic) manufacturers & users for their pressure controlling problems. It is very challenging to maintain predetermined pressure in the presses to produce a good quality product. Many times product is rejected due to increase or decrease in pressure which costs to manufacturer very high. Independent electronic module for die cushion & counter balance Due to manually controlled pressure by regulator of cushion & counter balance the following drawbacks has removed by using above automatic pressure controlling system. Cushion Production Was Less (Due To High Pressure Setting Time) Production Rejection Was High (Due To Not Exact Setting Of Pressure As Components Were Required. Hard In Machining. (High Cushion Impact On Slide, Due To High Cushion Pressure) Not Proper Shape Of Component. (Due To Less Cushion Pressure) Counter balance Motor Taking High Current When Balance Pressure of Counter Is High. Motor Taking High Current When Balance Pressure of Counter Is Low. Slide Coming Down May Cause Of Accident, Due To Not Proper Counter Balance Pressure As Per Slide And Die Weight. Automatic pressure controller Easy To Set Pressure for both Cushion And Counter Balance. Set Both Pressure as Per Component’s Requirement Once And Forget It. High Production and No Rejection. Less Power Consumption. Improve Product Quality And Do Safe Production. Features: Designed to suit the Indian environmental conditions Inexpensive in comparison to other solutions Precision & accurate pressure setting Wide application range Reliable & dependable User friendly with standard warranty Customized solutions available Standard Specifications: Application- Suitable for presses (Die Cushion & Counter Balance) Display- Two 20 x 4 lines LCD with back light. Analog Input- Two Analog inputs for Strain Gauge type Pressure Transducer. Digital Inputs- 8 Digital Inputs. Outputs- 8 Relay outputs for Machine operation. Function mode- Auto & Manual. Calibration- Simple calibration procedure for Pressure Transducer. Keypad- 4 keys to enter parameters & operation control. Indication- LED For (Pressure – Fill, Pressure – Ok & Pressure – Exit). Buzzer- For low & High Pressure status. Settable parameters- Air low & High Limits. Controller- Two independent controllers for Cushion & Counter Balance.

Electronic Pressure Controller

Get Price Quote

The Electronic Pressure Controllers, which we deliver, have maximum working presure of 10Bar. Owing to our speedy distribution network, we are capable to render quickly and hassle free deliveries. For ensuring safety of the products during handling, warehousing and transportation, we make use of quality packing material. Moreover, the task of packaging is undertaken by the experts.

Saginomiya TNS-C1100PL3Q Switch

4,000 Per Piece

1 Piece (MOQ)

Pressure Controller

Get Price Quote

• Pressure ranges from vacuum to 3,000 psi (200 bar) • Precision model accuracy of 0.005%RD + 0.005%FS • Standard model accuracy of 0.02%FS • HART Communication and Profibus PA (only 780) • Control stability of 0.003%FS • Easy-to-use icon based user interface

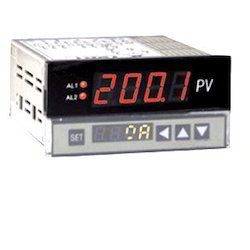

Pressure Indicator Controller

4,800 Per Piece

1 Piece (MOQ)

DH Digihelic Differential Pressure Controller

Get Price Quote

DH Digihelic Differential Pressure Controller The Series DH Digihelic® Differential Pressure Controller is a 3 in 1 instrument possessing a digital display gage, control relay switches, and a transmitter with current output. Combining these 3 features allows the reduction of several instruments with one product, saving inventory, installation time and money. The Digihelic® controller is the ideal instrument for pressure, velocity and flow applications, achieving a 0.5% full scale accuracy on ranges from 0.25 to 100 in. w.c. The Digihelic® controller allows the selection of pressure, velocity or volumetric flow operation in several commonly used engineering units. Two SPDT control relays with adjustable dead bands are provided along with a scalable 4-20 mA process output. In velocity of flow modes, a square root output is provided on the 4-20 mA signal to coincide with the actual flow curve. The Series DH provides extreme flexibility in power usage by allowing 120220 VAC and also 24 VDC power which is often used in control panels. Programming is easy using the menu key to access 5 simplified menus which provide access to: security level; selection of pressure, velocity or flow operation; selection of engineering units; K-factor for use with flow sensors; rectangular or circular duct for inputting area in flow applications; set point control or set point and alarm operation; alarm operation as a high, low or highlow alarm; automatic or manual alarm reset; alarm delay; view peak and valley process readings; digital damping for smoothing erratic process applications; scaling the 4-20 mA process output to fit your application's range; Modbus® communications; and field calibration. With all this packed into one product it is easy to see why the Digihelic® controller is the only instrument you will need for all your pressure applications.

Pressure Controller

Get Price Quote

4 Digit 7 Segment LED -1 to 1000 Bar in different ranges ±0.25% of FS Accuracy Selectable any two scales (Bar, Psi, Kgcm2 etc.) 14" NTP male for pressure connection 230V AC 50Hz Supply One set point with relay output Zero adjustment provided Size: 96x96x110 mm

Differential Pressure Controllers

38,000 - 42,000 Per Piece

1 Set (MOQ)

Digital Differential Pressure Controller

10,500 Per Piece

Our company has a convenient and noncomplex payment procedure. Patrons can make payments through a method with they are comfortable. We are open to receiving payment online or offline. Our organization is one of the steadfast providers of the finest range of our product in Mohali(India).

Allen Bradley pressure control

1,000 - 20,000 Per piece

1 piece (MOQ)

I'm pleased to introduce Yadav Marine Equipment & Scraps, your go-to supplier for a wide range of marine products sourced from Alang, India's largest ship breaking yard. Our product offerings include hydraulic and pneumatic valves, automation components, sensors, pressure transmitters, and various store products. For inquiries, please reach out to us via WhatsApp or email. We're here to serve your needs.

Electronic Pressure Controller

Get Price Quote

We are offering electronic pressure controller. * netel gas chromatograph model chrom lite gc-3000a with single flame lonization detector, with one packed or one splitsplit-less injection port. * electronic pressure controller (epc) provides excellent performance with capillary columns. *3 independent heated zones up to 400 c for individual control of injector, detector and oven. *higher sensitivity flame ionization detector requires no make up gas due to unique zero dead volume design. *32 keys for setting of the parameters & eight status l.e.d. Indications including oven ramp status. * pc control communication with rs. 232.

Nakakita Seisakusho Indicating Pressure controller

Get Price Quote

We have available following Ships spareparts for Sale: Product-Pressure Controller Product-Nakakita Seisakusho Type-NS-PS-732 Sr no-32K410 Date-23-3-82 If any requirement then please contact us on +91 97279 70078.

Intellicuff Pressure Controller

40,000 Per Piece

5 Piece (MOQ)