failure modes effects analysis service

Get Price Quote

Failure Modes and Effects Analysis (FMEA) Services identify and address potential failure points in products, processes, or systems before they occur. This structured methodology evaluates possible failure modes, their causes, and effects to prioritize risks based on severity, occurrence, and detectability. FMEA services help organizations implement corrective actions to mitigate risks, improve reliability, and ensure quality standards. Applicable across industries such as automotive, aerospace, healthcare, and manufacturing, these services enhance safety, reduce costs, and optimize performance. By fostering a proactive approach to risk management, FMEA services enable businesses to deliver dependable solutions that meet customer expectations and regulatory requirements.

failure analysis services

Get Price Quote

The organization with its vast experience in Failure Analysis has expertise to identify causes for failure of machinery/components and provide remedial solutions to prevent recurrence of failures. The solutions include material selection, design modifications maintenance plus operational practices.Also with Such studies, we help organizations to make warranty claims wherever manufacturing faults/ service faults are identified as failure cause for components/equipment. Payment Option : Bank Name: Axis Bank Branch: Dombivli East Branch Account name: Mumbai Institute of Metallurgy Quality & Management Account No: 125010200005050 Proprietor: Senapati Ramanathan

Looking for Product Analysis Services Providers

failure analysis services

15,000 - 150,000 Per

Based in Thane (Maharashtra, India), we are offering failure analysis services. We have the best and experienced team of professionals that is capable of analyzing the failure within any system. We use the most advanced techniques and devices to analyze the failures and identify reasons for failure so that corrective actions would prevent reccurrence of such failures. We make sure to meet the client’s expectations andsatisfy them, offer reliable failure analysis services. Contact us anytime. Our services also include remaining life assessment of plant and machinery.

thermal analysis service

Get Price Quote

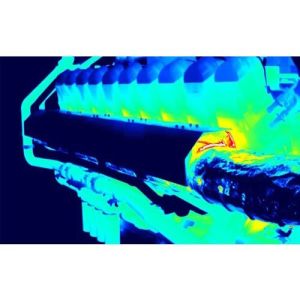

Our Thermal Analysis Service employs sophisticated tools to assess and optimize thermal performance in engineering systems. Utilizing advanced software, we simulate heat transfer, thermal stresses, and temperature distribution within components or assemblies. This service aids in evaluating material behavior under various thermal conditions, ensuring optimal designs for efficiency and reliability. With a focus on precision and accuracy, we provide invaluable insights to enhance thermal management, improve product durability, and mitigate potential thermal-related issues across diverse industries.

PCB Thermal Analysis Services

Get Price Quote

Our PCB Thermal Analysis Services offer detailed insights into the thermal performance of your printed circuit boards. Using advanced thermal imaging and simulation tools, we assess heat distribution, identify hot spots, and evaluate thermal management strategies. This analysis helps in optimizing component placement, improving heat dissipation, and ensuring that your PCB operates reliably under various thermal conditions. Whether for high-power electronics or sensitive applications, our thermal analysis ensures your designs meet performance and durability standards, reducing the risk of overheating and failure.

Failure Analysis Service

Get Price Quote

Our Company has the well-known name in this domain for offering the best quality Failure Analysis Service. In failure analysis, the mechanical, physical, and chemical investigation is made into the cause and sequence of events that lead to a product condition in which the product no longer meets expectations. In this service, we conduct analysis on failed engineering components and resolving failure issues.Other details: Brief Information of the failed component and Prior service history Condition prevailing during the failure Mechanical and metallurgical evaluation of failed component Event summary Recommendations for prevention and equivalent substitutions

Traffic Analysis Services

5,000 - 100,000 Per Lift

1 Lift (MOQ)

Any large building will always need an efficient vertical transportation system in order to work smoothly for its occupants. Traffic analysis is the study to find out the number of lifts required , the capacity and speed of operation.we can do this analysis for car parks and shop floor too.

failure analysis services

Get Price Quote

Failure is a part of life and so does it is a part of work, functionality and process. Whenever there is a failure in terms of project, process, machinery, etc, a thorough analysis helps a lot. We at Techinova Engineering Analysis Services LLP have the best analytical team that know their job well. they have helped a lot of clients getting the best failure analysis services which have helped the business to avoid any uncalled situations. Our services are designed keeping the requirements of our clients in mind which mean they can get what they are looking for with ease. We are easily accessible and are ready to take up new tasks and challenges.

Paint and Coating Failure Analysis Service

Get Price Quote

Geetanjali Enterprises is a Mumbai (Maharashtra) based organization that specializes in paint and coating failure analysis. We are backed up with years of experience as well as a team of veteran paint and coating failure analysts that enable us to provide accurate causes and reasons regarding all kinds of paint and coating failures. Our analysis has helped many companies to avoid wastage of manpower and money caused due paint and coating failures.

failure analysis services

Get Price Quote

Investigation and identification of root cause of failures (design, material factors, manufacturing processes, quality assessment, application, handling, maintenance, service conditions, user habits etc.) and suggesting corrective actions & preventive measures.

Analysis Services

Get Price Quote

The analysis services are iterative in nature and require the domain expertise to interpret the results from the analysis and modify the models to validate and optimize its design. The core activities involve specifying boundary conditions to the mesh and applying the loads. These loads can be a combination of static, dynamic, thermal etc

Electrical Failure Root Cause Analysis Service

Get Price Quote

This is a special study involving identification of reasons for recurrent Electrical failures or faults causing down time or loss of production/ revenue. This is a comprehensive study conducted by Subject Matter Expert and team of Expert Electrical Engineers to identify the reason for failure. Use of high end testing equipements under guidance of Experts with expertise is involved in this study.

piping stress analysis

Get Price Quote

1 Meter (MOQ)

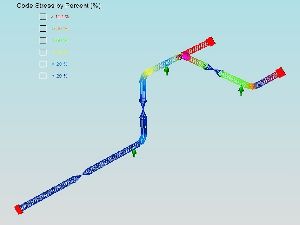

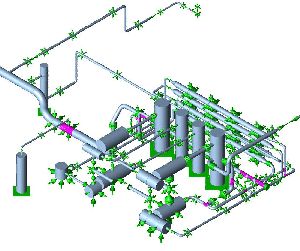

our pipe stress analysis package includes: static load analysis in piping systemsdynamic load analysis in piping systemsthermal stress analysis in piping systemsstress check due to flow of service mediumstress check due to process parameters like temperature, pressure, density of service mediumpipe hangers and support design & selectionanalysis of loads on nozzles & flangesdesign of pipe racksstructural stress analysisvessel & equipment structure design analysismanufacturing and fabrication of piping spoolsfabrication of steel structures .

piping stress analysis

30,000 Per Units

Core Expertise Piping Stress Analysis ASME B31.1 And B31.3 Piping Isometric Pipe Layout P&I Diagram Piping Engineering Consultancy Boiler Design And Modification Power Plant Consultancy Piping Vibration Problems Project Management EPC Projects

product analysis services

Get Price Quote

undefined undefined (MOQ)

We are professional laboratory that specialises off chemical solution and products to clean black notes,green and white notes for mores information kindly revert back with you email address to have full details.

failure analysis

Get Price Quote

Failure analysis is the process of collecting and analyzing all the data to identify the cause of a failure and how to prevent it from recurring. It is an important discipline in many industries, such as the electronics industry, petrochemicals industry where it is a vital tool used in the development of new methods & products and for the improvement of existing methods & products. The main principle of failure analysis is a forensic inquiry into the method or product upon the failure. Such inquiry can be conducted using scientific analytical methods such as mechanical, Non-destructive and electrical testing measurements, or through speculative approach when the data is not available but an action has to be taken. Failure analysis and prevention are important functions to all of the engineering disciplines. The materials engineer often plays an important role in the analysis of failures, whether failure occurs during manufacturing or production processing or component/product fails in service. Features of root cause failure analysis capabilities include: Evaluation of field failures Evaluation of life cycle test failure Identification of failure mode Contamination analysis Corrosion and environmental effects Photographic documentation Broad failure analysis experience Fracture evaluations Identification of product defects Failure analysis of polymer and rubber components Spectro’s Failure Analysis reports provide a clear picture of the root cause, and include recommendations to avoid future failures - from component design, through material selection and processing. Over the last few years many such types of evaluations have been performed.

HPLC Analysis

Get Price Quote

High-performance liquid chromatography, formerly referred to as high-pressure liquid chromatography, is a technique in analytical chemistry used to separate, identify, and quantify each component in a mixture.

HPLC Analysis

Get Price Quote

We are providing hplc analysis: isocratic analysis, gradient analysis gc analysis viscosity analysis atomic absorption spectroscopy for metal analysis infrared spectroscopy for organic and inorganic compound analysis uv visible spectroscopic analysis standard error of mean graph (sem) method development.

Fuel Analysis

Get Price Quote

We are providing density ash water content sediment carbon residue carbon nos. By gc-capillary flash point aniline point cloud point pour point kinematic viscosity at 40 & 100 0c copper corrosion test