3 & 5 ply Fully Automatic corrugated board Production line

15,500,000 - 17,500,000 Per Set

1 Set(s) (MOQ)

Penne Pasta Production Line

2,200,000 Per Piece

1 Piece (MOQ)

Best Deals from Production Lines

5 Layer Automatic Corrugated Board Production Line

300,000 - 3,500,000 Per Piece

1 Piece (MOQ)

Welding Electrodes Production Line

Get Price Quote

We are one of the most promising exporters of Welding Electrode Production Line in India. Our machinery render trouble free performance for longer period of time. We provide comprehensive range of products such as welding electrode manufacturing machinery, welding electrode equipments, welding electrode accessories and welding electrodes. Products served by us are made up of quality raw materials, which increase their durability and efficiency. Features: Rugged construction Longer service life Robust construction Low Operation cost

Automatic Five Layer Speed Corrugated Paper Board Production Line

Get Price Quote

We have gained prominence as the Manufacturer, Exporter & Supplier of Automatic Five Layer Speed Corrugated Paper Board Production Line from Punjab, India. Used for production of corrugated cardboards, our Production Line has garnered widespread appreciation across the globe. We have developed a strong distribution network, hence, we can be counted upon for delivering Automatic Five Layer Speed Corrugated Paper Board Production Line within stipulated time. Salient Features : Mill roll stand the two holder can lift and lower independently. Drum type Pre Dryers increases drying capacity of the maching. Single Facer - The diameter of the corrugating roll is 280 Om - 380 Om. Complete with Pneumatically controlled upper roll, Pressure roll & gum rolls. Duplex gluing unit can be coantrolled separately. Double layer gluing machine : Using the top and middle layer for gluing and the bottom for conveying the reel paper. Drying machine - Double baker is made of 17 Pieces of heater plate. Pneumatic strain device and conveyor belt spearate automatically once the power cut. Slitting machine - Slitter and Scorer is provided for online slitting & creasing onboard. CNC Slitter & Scorer can also be provided. CNC cut-off gives precision cut and its helical cutting knife ensures minimum stress & load while butting. Different work order can be stored and can be changed even when production line is running.

Palm Kernel Oil Production Line

Get Price Quote

Palm Kernel Oil Production Plant We are manufacturer & exporter of Palm Kernel Oil Production Plant on turnkey basis. We manufacturer machinery & equipment for Palm Kernel Oil Production Plant by using high quality material and modern technology at our state of the art machining facility. We can also customize these plants as per our valuable client’s requirements. The Palm Kernel Oil Production Plant is in great demand across various countries where the production of Palm Kernel is significant. Basic equipment / machinery required for the Palm Kernel Oil Production Plant is as under: · Seed Cleaner · Oil Expeller / Oil Press · Filter Press with Pump · Bucket Elevator · Screw Conveyor · MCC/Control Panel The Palm Kernel Oil Production Plant crushing capacity starts from 15 TPD onwards. The Palm Kernel Oil Production Plant is designed, manufactured, supplied and installed & commissioned on turnkey basis. Are You Looking to Start a New Palm Kernel Oil Production Plant or Further Expansion? Don’t hesitate to contact us, if you are interested to get a customised quotation with Equipment Details and Prices for Palm Kernel Oil Production Plant.

High Speed CNC Angle Steel Shearing Production Line

4,500,000 Per set

1 Piece(s) (MOQ)

1.function: punching marking & shearing for angle steel 2.size of angle steel(mm): 40x40x3-200x200x20 3.punching capacity max.(mm):φ26x20 & (oval hole 22.5x40mm thickness 16mm) q345 7.max length of raw angle(mm):14000 .

5 Meter Industrial Conveyor for Soap Production Line

70,000 - 155,000 Per

1 Piece (MOQ)

Residential Heat Pump Prodcution Line

Get Price Quote

Water Test Halogen test Gas Leakage test

Central Filled Soft Candy Production Line

Get Price Quote

We have a well-maintained and spacious storage space and thus, we are flexible enough of meeting the urgent needs. Furthermore, we by no means go out of stock and thus we maintain year round accessibility of all the products. We are counted amidst the well-known names based in Pune(India) and cater to every nook and corner.

Cement Production Line

Get Price Quote

We are offering cement production line. Laxmi en-fab pvt ltd. Manufacturer of cement production line. We sell the latest cement production equipment. Our machine is enjoying good popularity in india for our machine is with good quality and reasonable price. We can provide a series of service from designing, manufacturing, installation, debugging to commissioning for the complete unit of cement production line and its accessories, such as material crushing, pre-homogenizing stock yard, material pulverizing, raw meal homogenizing silo, clinker burning, pulverized coal preparation, cement pulverizing, cement packing and other electric automation equipment, water supply & drainage engineering equipment, refractory material, grinding element till laboratory equipment etc.

Fruit Juice Processing Line

Get Price Quote

We ensure our entire range of products is per domestic as well as transnational quality standards, optimum grade and worth the price paid by purchaser. Based in Pune(India), we are one of the most sought after names when it comes to qualitative and cost-effective products.

Flat Drip Irrigation Pipe Production Line

Get Price Quote

Drip irrigation is defined as any watering system that delivers a slow moving supply of water at a gradual rate directly to the soil. Drip irrigation, which is also sometimes referred to as micro irrigation or trickle irrigation, consists of a network of pipes, tubing valves and emitters.

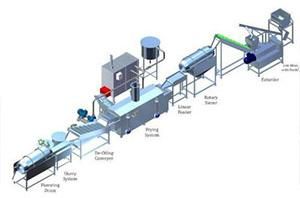

Fully Automatic Kurkure Production Line

Get Price Quote

The Fully Automatic Kurkure Production Line, delivered by us, is reckoned due to its high performance. Strong industrial base along with a wide area network, we deliver the range in the stipulated time span. We have with us a well-maintained and capacious storage unit that is facilitated by advanced and automated warehousing system, which is operated and supervised by experts only.

Pet Strap Production Line

Get Price Quote

Project evaluation 1.1 Raw material & Final product Raw material - 100% PET recycling bottle flakes - Viscosity increaser (optional, model percentage approx. 5%) - Special high concentration color master batch (optional, percentage 1-2%) Output capacity 180-200kg/h - Max. affordable pull of 100% PET recycling bottle flake with viscosity increaser: 800-1000kg Picture/Diagram Product specification reference Method of adjustment Thickness 0.5-1.5 mm Adjust stretching speed by manual Width (mm) 5-20 mm Adjust die head orifice by manualApplication: cotton Ginning bales,Heavy engineering goods packing

One Step Short Spinning Production Lines

Get Price Quote

HDPE Pipe Production Line

Get Price Quote

1 Piece(s) (MOQ)

HDPE Pipe Production Line that we offer is available in the production capacity ranging from 50kg to 250 kg /hr. We make sure that HDPE Pipe Production Line is well-tested by experts before delivery to the clients. HDPE Pipe Production Line, offered by us,complies with high industrial standards. We are capable of delivering HDPE Pipe Production Line at stipulated time frame. Size : Ranging from 20 mm to 250 mm. Types Available PVC Pipe Extrusion LinePE, PVC Single Corrugation Pipe Production LinePipe Production Line (PVC, PE)PP-R PE HDPE Pipe Production Line

Rice Bran Oil Production Line

200,000 Per Piece

Nonwoven Carpet Production Line

Get Price Quote

We offer nonwoven Carpet Production Line. Technical Specification: Nonwoven Carpet Production Line Machine width 3600 mm-4600 mm Stiching Frequency 1000-1200n min Feeding Speed 0.6-6m min General Power 128-218kw