Coconut Oil Production Machine

788,500 - 871,500 Per piece

1 piece (MOQ)

Automobile & mass production Meal cutting Bandsaw Machine

1,800,000 - 5,500,000 Per Piece

1 Piece (MOQ)

This Bandsaws are used in automotive workshops to customize auto parts and for vehicle maintenance. The demand for fully automatic bandsaws in the automotive industry is increasing due to the need to cut hard metals

Best Deals from Production Machinery

Special Purpose Production Machine

Get Price Quote

1 Piece (MOQ)

High Production Pasta Machine

4,500,000 Per Piece

-21 Piece (MOQ)

Automatic cotton cutter machine with lot production facility

30,000 Per piece

1 Piece (MOQ)

USP of cutter machine: 1. Adjustable Speed of machine. 2. Adjustable Hold Time. 3. Lot production facility. 4. Digital display for all functions. 5. Auto adjust roller suspension. 6. Machine can handle from 1.4 gram to 5 gram per meter cotton. 7. Production up to 1kg per hour. 8. Buzzer sound for alert. 9. Machine body made from 3D printing technology. 10. Machine runs on self made Software and PLC system. 11. 24 watt power consumption.

High Production Press Machine

Get Price Quote

Aac Blocks Production Machine

Get Price Quote

Laxmi EN-Fab designs and manufactures AAC lightweight block making plant, to meet the specific requirements of the market and customers. As a new building material, AAC lightweight block production line fulfills the demand of concrete industry, which requires to save the natural resources and protect the environment. With Germany technology and our own R&D, we provide our customers state-of-the-art AAC lightweight block making plant. AAC is produced out of a mix of cement, lime, fly ash, gangue, river sand and aluminium powder etc., through batching, mixing, casting, cutting and autoclaving. AAC has the advantages of extremely light weight, high compressive strength, excellent thermal insulation, great acoustic insulation and high fire resistance. AAC can be produced in a large variety of sizes, from stand blocks to large reinforced panels, and it can be cut, sawn, drilled, nailed and milled like wood, making it an extremely workable product. AAC is environment-friendly and new building material. Annual Capacity (300 days) Power Daily Capacity Cycle Time No. of Autoclaves 50,000 m3year 400 kW 166 m3day 10 hours 2 (¢2 × 26.5) 100,000 m3year 500 kW 333 m3day 10 hours 4 (¢2 × 26.5) 150,000 m3year 630 kW 500 m3day 10 hours 6 (¢2 × 26.5) 200,000 m3year 720 kW 666 m3day 10 hours 8 (¢2 × 26.5) 300,000 m3year 1,186 kW 1,000 m3day 10 hours 8 (¢2.85 × 32.5) *Theoretical output with suitable aggregates and materials. Advantages Large variety of sizes: AAC lightweight block production line enjoys a large variety of sizes, from standard blocks to large reinforced panels. Excellent thermal insulation: It achieves very high thermal energy efficiency due to its very low thermal conductivity. This benefits the saving on heating and cooling costs. Extremely light weight: It weighs approximately 50% less than other comparable building products. High compressive strength: Its solid structure makes it highly load bearing. The entire surface area is used in structural calculations to improve its strength. High dimensional accuracy: Thanks to its dimensional accuracy, AAC is extremely easy to install, as no thick mortar is required. Great acoustic insulation: Its porous structure provides a high acoustic insulation. High fire resistance: It has an extremely high fire rating of at least 4 hours and more. Termite resistance: It cannot be damaged by termites or insects. High workability: Thanks to its excellent sizeweight ratio, the construction with AAC is very rapid. Although AAC is a solid building material, it can be cut, sawn, drilled, nailed and milled like wood. This benefit makes it an extremely workable product.

YL-80 Serial Production Machine

Get Price Quote

Round Cotton Pads production machine

Get Price Quote

1 Piece(s) (MOQ)

Dear Sir. We are introducing ourselves as manufacturers and exporters of cosmetic machines and special purpose machines for any applications. 1,Nail polish remover cosmetic cotton pad production machine, with online liquid filling arrangements, automatic pad counting device, Round and Square shape. Die cut pad. Machine is equip with Using latest technology, PLC, HMI control panel. Servo driven. 2, Make up remover cosmetic cotton Pad production machine. Round and square shape. Die cut pad. 3, Cotton ball making machine.

Fast Production Disposal Glass Making Machine

Get Price Quote

zip lock polythene bag production machine

770,000 - 800,000 Per piece

zip lock polythene bag production machine (LD)

Automatic Square Net Production Machine

Get Price Quote

production machinery

Get Price Quote

1 Piece (MOQ)

High Production Carding Machine

Get Price Quote

We introduce ourselves as a Supplier of High Production Carding Machine. High Production Carding Machine is designed to meet almost all stringent requirements of the textile industry. High Production Carding Machine has designed & developed with 100% indigenous technology. High Production Carding Machine can process various types of cotton & synthetics at high speed. Details Working Width : 1016 mm Feed : Lap or Chute Cylinder Diameter Over Clothing : 1290 mm Doffer Diameter Over Clothing : 673 mm

Cigarette Production Machine

Get Price Quote

Cigarette Production Machine Parts used in Cigarette production units, characterised by perfect surfaces achieved by complex machining techniques.

Automatic Five Layer High Speed Corrugated Paper Board Production Line

Get Price Quote

This production line is suitable for large quantity automatized manufacturing and it can produce good quality corrugated cardboard which can meet nationalize standard completely. Higher productivity, better paper board quality, adoption of central control system, simple and easy operation, convenient to repair and maintenance, reliable and sate, greatly lower degree of manpower requirement. This production line adopts the most updated source-saving mode which get heat from the high-temperature guiding oil compared with the steam heating it reduce the source by 60% so that cut the cost effectively. It is economical ideal product and suitable for big and medium carton manufacture.

production machinery

Get Price Quote

1 Piece(s) (MOQ)

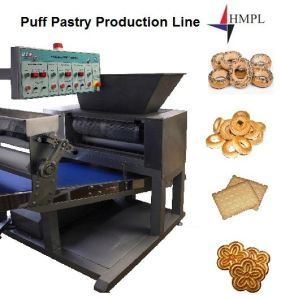

Puff Pastry Production Line Machine

Get Price Quote

>> Puff pastry and dough >> Hard biscuit, soft biscuit and cracker >> Bread rolls >> Sponge bases for cakes salty and sweet bread sticks >> Taralli and bread sticks grissini >> Filo dough and products made of it (burek, vertuta) The priority principle of our company is the individual approach to each client, as well as to the development of the project, starting from the configuration of lines and the design of confectionery machine layout to installation and commissioning works. We try to give full attention to the specifics of every customer’s business, the needs and requirements of his production. We take into account conditions of production and technological processes, provide constant technical support and advice. We offer not only standard production lines, but also individual, and even exclusive developments. Besides, we offer not only lines in the set, but also separate units or component elements of confectionery equipment for sale.

Zeiss Centermax Production CMM Machine

Get Price Quote

The packaging commences strictly under the guidance of veteran experts and professionals, thus ensuring optimum packaging, keeping the products safe from various damaging factors. With meticulousness, hard work and commitment, our organization has developed in order to become a reputed trader in Delhi(India). Coordinate measuring technology for production Machine design optimized for integration Temperature stability from +15ºC to +40ºC Pneumatic vibration insulation Robust machine design Temperature Variable Accuracy (TVA) : The accuracy of measuring machines is usually only given for the ideal temperature. Not with CenterMax: thanks to the TVA formula, the accuracy of this system can be exactly determined for different temperatures. Navigator technology package Automatic generation of the ideal measuring strategy Tangential approach Helix scanning Dynamic stylus calibration VAST Performance Kit FlyScan QuickChange Options Touchscreen – unaffected by oil and dirt Pneumatic stylus rack Safety equipment Rotary table Available Software CALYPSO GEAR PRO Solutions Moventas Sandvik

COMBI(Dry Ice Production and Dry Ice Blasting )

Get Price Quote

The IceTech COMBI and its accessories have been developed with the intention of manufacturing an automated cleaning system which both meets the requirements especially of industrial companies for a continuous cleaning process, and minimizes consequential costs of machine / plant cleaning and maintenance. The IceTech COMBI combines dry ice pellet production and dry ice blasting. Therefore high-density dry ice pellets will always be available on site in the exact quantity required. Several Functions in one Machine The IceTech COMBI combines several units and functions: :: A pelletizer unit:: A Dry Ice Blasting unit:: Optional distribution system to facilitate the connection of several blasting guns:: Optional integration in plant control units and automation processes The IceTech COMBI continuously produces Dry Ice Pellets directly into the pellet tank of the Dry Ice Blasting unit. From there the Dry Ice Pellets are transported through a distribution system to one or more blasting guns or robots.