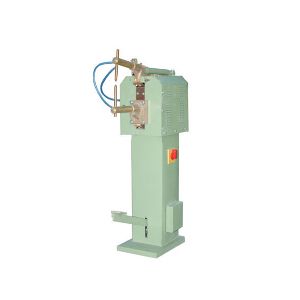

Projection Spot Welding Machine

50,000 - 1,500,000 Per piece

1 Piece (MOQ)

VR METALS AND ENGINEERS ISO 9001:2015 CERTIFIED COMPANY WE ARE MFG. These are specially designed and manufactured with proprietary manufacturing process of Weld for longer life and to ensure the correct location of the Nut or Stud to be welded. Locating pins for nuts are available in various materials like ceramic, coated steel and stainless steel. Pneumatically operated nut welding electrodes also available on request.

Projection Welding Machine

Get Price Quote

Application: Weld-nuts To Sheets. Fastener-bolts To Sheets Handles To Various Sheet Assemblies Including Drums & Containers. Cross Wire Welding, For Wire Mesh. Pins, Brackets To Different Assemblies. Welding Of Various Automobile Components.

Best Deals from Projection Welder

Projection Welding Machine

Get Price Quote

Weltronics’ rigidly designed range of Projection Welding Machinesis suitable for weld thick material at low speed utilizing on their short length arms. Furthermore, our range of projection welding machines helps us in welded steel construction making it a suitable choice for bulk production & consistent service in the manufacturing of wide range of cross spanners, scooter rim studs, bellows and filters produce heavy duty lathe with utmost efficiency. As a leadingProjection Welding Machines Manufacturer, Supplier and Exporter we ensure easy to install and operate range of projection welding machines with customization to meet the rising needs and demands of the clients. These are designed to give a compact streamline external layout to ensure maximum resistance to any kind of mechanical deflection. Please refer our contact page to arrange for a demo at our facility in MIDC Bhosari, Pune, India.

Projection Spot Welding Machine

145,000 - 175,000 Per piece

1 Piece (MOQ)

Seam Projection Welding Machine

Get Price Quote

Helmet Projection and Surface Friction Testing Machine

Get Price Quote

1 Piece (MOQ)

Projection Welder

Get Price Quote

"H" Class insulated copper wound water cooled welding transformer. Pair of thyristors for linear heat control from 5 to 95 %. Equipped with C-MOS control panel Model PM 201A or Micro Processor control panel Model PM20XP. Pneumatic cylinder with solenoid valve and filter, lubricator, regulator assembly with pressure gauge and push in type connectors. Water cooled electrode holders with Copper Chromium Zirconium electrode tips for long time. Press Type Spot Welder 35 to 350 KVA.

Projection Welding Machine

100,000 - 1,000,000 Per Piece

1 Set(s) (MOQ)

Capacitor Discharge Projection Welding Machine

Get Price Quote

Spot Projection Welding Machine

Get Price Quote

spot cum projection welding machine

Get Price Quote

1 Piece (MOQ)

Salient Features All Operational Controls - Air, Water And Solid State Electronic - Are Machine Mounted, For Easy Access, Safe And Simple Maintenance. Weld Sequence Controller, Sophisticated Quartz Timer With Squeeze, Weld, Hold And Off Timings With Single/repeat Cycle Facility, Weld Timing Being Controlled By Thyristor Circuit, Heat Controllable From 5% To 95%. Electrode Cushion Control Adjusts The Descent Of The Upper Electrode To Any Desired Speed And Completely Eliminates 'hammer Blow'. Sturdy Ram Assembly Permits High Speed Operation.

SPOT PROJECTION WELDER

Get Price Quote

Spot Projection Welder support optional water hoses that are used for cooling the electrodes during welding. These spot welding machine consist of tool holders and electrodes wherein tool holders are used for holding the electrodes firmly in place. It can be used for various applications, such as spot & projection welding, nut welding of automobile components & sheet metal components. It is efficiently made with the sincere efforts of our workers. Usage of high quality raw material, extensive techniques and great manufacturing unit. Features Corrosion resistance Precision functioning Durable High efficiency High performance Affordable prices.

resistance projection welding machines

32,000 Per Piece

Press type air operated Projection Welders are designed for high speed production work to meet the needs of a vast number of metal fabrication shops. A variety of electrodes and toolings can be fitted to render them suitable for projection welding, cross wire welding, electro-brazing, hot riveting, electro-forging and upsetting. Fully solid state electronic controls (Microprocessor based or CMOS based) are available for using with machine in order to obtain consistent and accurate weld results on a wide range of materials at a high-speed automatic operation. These machines are designed and manufactured conforming to the Indian Standard Specification No. IS:4804 Part I and III by a team of highly experienced engineers in welding technology. Specifications: Standard Ratings: 50, 75, 100, 150, 250 and 300 KVA @ 50% duty cycle. Type: Air operated, stationary press type projection welding machine with pneumatic cylinder mounted directly on the upper arm.

spot cum projection welder

Get Price Quote

We are offering spot cum projection welder. Range: 30 kva - 200 kva 6 standard models to choose from custom built welders. Highly versatile machines with many new features. Salient features all operational controls - air, water and solid state electronic - are machine mounted, for easy access, safe and simple maintenance. Weld sequence controller, sophisticated quartz timer with squeeze, weld, hold and off timings with singlerepeat cycle facility, weld timing being controlled by thyristor circuit, heat controllable from 5% to 95%. Electrode cushion control adjusts the descent of the upper electrode to any desired speed and completely eliminates 'hammer blow'. Sturdy ram assembly permits high speed operation. Technical specifications of spot cum projection welding machine.

PROJECTION WELD MACHINES

Get Price Quote

Projection Welders are used for that components those are not in range of spot welders.

Projection Spot Welder

Get Price Quote

Press type air operated Projection Welders are designed for high speed production work to meet the needs of a vast number of metal fabrication shops. A variety of electrodes and toolings can be fitted to render them suitable for projection welding, cross wire welding, electro-brazing, hot riveting, electro-forging and upsetting. Fully solid state electronic controls CMOS based are available for using with machine in order to obtain consistent and accurate weld results on a wide range of materials at a high-speed automatic operation. These machines are designed and manufactured conforming to the Indian Standard by a team of highly experienced engineers in welding technology. Specifications: Standard Ratings: 50 @ 50% duty cycle. Type: Air operated, stationary press type projection welding machine with pneumatic cylinder mounted directly on the upper arm. Construction: Main frame of the machine is of heavy, rigidly welded mild steel construction, streamlined appearance with maximum resistance to deflection. Transformer enclosed in the main frame and pneumatic accessories mounted on the side of the machine and upper and lower arms mounted directly on the frame. Current is carried from the upper transformer terminal to the upper platen tooling through a 'U' shaped laminated copper flexible link designed to provide rolling action as the welding head reciprocates during operation. The welding head is of antifriction type. The pneumatic controls mounted on the side of the machine. The operating control station mounted on the machine is clearly visible and within easy reach of the operator. Standard Throat Depths: 300, 450, 750 mm. Welding Transformer: Transformer conforms to water cooled, class 'F' insulation with thermo switch protection for overloading.

Press Type Projection Welder Machine

Get Price Quote

Press type air operated Projection Welders are designed for high speed production work to meet the needs of a vast number of metal fabrication shops. A variety of electrodes and toolings can be fitted to render them suitable for projection welding, cross wire welding, electro-brazing, hot riveting, electro-forging and upsetting. Fully solid state electronic controls (Microprocessor based or CMOS based) are available for using with machine in order to obtain consistent and accurate weld results on a wide range of materials at a high-speed automatic operation.

CD Projection Welding Machine

Get Price Quote

Current monitoring provision (optional) Digital volt meter indication Pneumatic & hydraulic operated type Product Advantages : Reduces large power required (KVA) demand Reduces power consumption Reduces negligible electrode worn out , results profit in welding cost Less blackening , distortion , marks , excellent , aesthetics No effects of line voltage fluctuation on welding Can work on diesel power generator set Can weld ferrous , non-ferrous , & dissimilar materials Can weld at heat sensitive region

Stick Projection PJS75 Welder Welding Machine

Get Price Quote

1 Piece(s) (MOQ)

Item Unit TIG400 Supply V 400+10% Phase Ph 2 Frequency Hz 50 Load Kva 75 Nominal Center mm 255 Pillat x Hallow

Spot Projection Welders

Get Price Quote