Pulse Jet Bag Filter

150,000 Per Piece

1 Piece (MOQ)

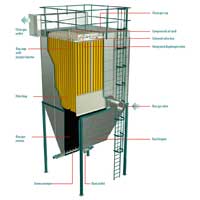

A pulse-jet fabric filter, often referred to as a pulse-jet baghouse, is a type of dust collector that utilizes a cleaning mechanism known as pulse-jet cleaning. This technology is commonly used in industrial applications to remove particulate matter from gas streams, helping to maintain air quality, protect equipment, and comply with environmental regulations.

reverse pulse jet bag filter

Get Price Quote

1 Unit (MOQ)

Best Deals from Pulse Jet Bag Filter

Pulse Jet Bag Filter

150,000 - 1,000,000 Per Unit

1 Piece (MOQ)

Pulse Jet Bag Filter

Get Price Quote

Pulse Jet Bag Filter has rectangular/ cyclonic design that ensures efficient separation of particulate matter from laden air coming out of various industrial processes. Pulse Jet Bag Filter is designed to meet dust collection application in Cement, Steel, Automobile, Rubber, Ceramic Industries and Rice and Flour Mills, Pulse Jet Bag Filter at economical price. Highlights Filtration area : 8 Sq.M to 3000 Sq. M Air Flow : 2,000 CMH to 200,000 CMH Longer service life Efficient performance

Pulse Jet Bag Filter

Get Price Quote

20 piece (MOQ)

Pulse Jet Bag Filter

Get Price Quote

The Pulse Jet Bag Filter offered by us comprises of fabric filter with fully automatic bag cleaning device by compressed air pulse. Reverse Pulse Jet Bag Filter serves for dry separation of dust from waste gas. These filters can filter heavy dust burdens and achieve desired collection efficiency at high temperature. Low maintenance cost, minimum power consumption, high filtration efficiency are the salient features of Long Bag Pulse-Jet Bag Filter available with us. Apart from this, we provide availability of Reverse Pulse Jet Bag Filter at the most competitive prices of the industry. We are named as one of the most illustrious Long Bag Pulse-Jet Bag Filter Exporters from India.

Pulse Jet Filter Bag

190 Per Piece

100 Piece (MOQ)

Pulse Jet Bag Filter

700,000 Per Set

Pulse Jet Bag Filter

Get Price Quote

100 Piece (MOQ)

Pulse Jet Bag Filter

Get Price Quote

Available with us, is Pulse Jet Bag Filter that helps in proper sealing between clean air chambers and raw gas. Besides, the Pulse Jet Bag Filter offered by us puts lesser pressure on the fabric and ensures high performance along with effective cleaning. Furthermore, this Pulse Jet Bag Filter is long lasting in nature. Attributes Compact in designLesser time consumed for bag change Lower Pressure dropConsumption of compressed airMaintenancePower consumptionHigh efficacy in filtrationSimple replacement of filter bagMinimum assemble work

Pulse Jet Bag Filter

150,000 Per Piece

1 Piece (MOQ)

Pulse Jet Bag Filter

Get Price Quote

We are offering pulse jet bag filter. yash filters have been successful in catering to the requirements of our esteemed clients by offering quality high temperature pulse jet bag filter. The offered range of high temperature pulse jet bag filter is tested after manufacturing process is over so as to ensure that only flawless products are dispatched at clients' premises. This range of high temperature pulse jet bag filter is known for its usage in different application areas like steel, sponge iron, cement, automobiles and allied. Our team of expertise is highly appreciated in the international market for our comprehensive range of high temperature pulse jet bag filter. The offered range is highly applicable in different fronts like different sheet metal processing, food & pharmaceutic industries, rubber processing and wood working. Along with this, the offered range of high temperature pulse jet bag filter is known for its attributes like simplicity, optimum efficiency, cost-effectiveness and very low outlet emission.

Pulse Jet Bag Filter

Get Price Quote

We are engaged in providing durable Pulse Jet Bag Filter that may be designed in Pulse air or Reverse air System. The Pulse Jet Bag Filter range is highly appreciated for better collection or efficient filtration. We offer the Pulse Jet Bag Filter at market leading rates to the valued clients. Special Features ON-LINE (with Hopper/side Entry) Pulsing & OFF-LINE Pulsing Low investment and maintenance cost and low assembly work Low power consumption combined with high filtration efficiency Good accessibility of compressed air supply system Simple filter bag replacement Compact construction and therefore modest floor space requirement Standard design pressure : ± 5000 Pa Designs for up to 12,000 Pa Unique design with combination of COMPRESSED AIR JET and REVERSE AIRFLOW cleaning Effective cleaning of Longer Filter Bags Fully automatic bag cleaning mechanism Available in square, modular and round shapes with top or side removal of bags Applications Aluminium Dust Aluminium Chloride Ammonium Sulphate Asbestos Bagasse Dust Calcium Oxide Carbon Black Cement Ceramic Clay Clinker Coal Detergent Fly Ash Graphite Gypsum Iron Ore Kiln Lime Limestone Milk Powder Saw Dust Silicon Carbide Soda Ash Mild Steel Sponge Iron Ferro Alloy Wood Sugar

Pulse Jet Bag Filter

15,000 Per piece

1 piece (MOQ)

Pulse Jet Bag Filter

150,000 - 200,000 Per Unit

150000 Unit (MOQ)

Pulse Jet Bag Filter

Get Price Quote

We bring forth the finest quality Pulse Jet Bag Filter in Kolkata, West Bengal. Our Jet Bag Filter is manufactured under the supervision of experienced professionals who use high-grade components and other materials to manufacture it. Our filter has durable finish and requires low maintenance. We provide Bag Filter with different specifications according to the requirement of buyers. Buyers can acquire Pulse Jet Bag Filter from us at competitive price.

Pulse Jet Bag Filter

50,000 - 10,000,000 Per No

1 Piece (MOQ)

Pulse Jet Bag Filters

Get Price Quote

We are highly acclaimed Manufacturer, Exporter and Supplier of Pulse Jet Bag Filters. The Pulse Jet Bag Filters are Bag Type Filters developed with new age designs for better life. The Pulse Jet Bag Filters are known for their lower power consumption and emission levels. We offer Customized Pulse Jet Bag Filters on the bases of application requirement and they are used where airflows are in large quantity, temperatures are higher than ambient or material to be handled is difficult. Features Lower pressure dropsHigher air-to-cloth ratios with better performance levelsLower floor space requirement Modular designs available starting from 1600m3/hr to 400,000m3/hrVariety of filter media available for different applicationsTool less installation/replacement of bag & cagesCan handle 250oC hot gasEasy to install & commission

Pulse Jet Bag Filter

Get Price Quote

Dust Collector system consists of a blower, dust filter, a filter-cleaning system and a dust receptacle or dust removal system. It is distinguished from air cleaners which use disposable filters to remove dust. The dust-laden air enters the Bag Filter. The dust powder separates inside the bag air filter chamber. The air is uniformly distributed avoiding channeling while the powder is separated. Initially a coat of material forms on the bags. Subsequently, the coat acts as the filtering medium. The dust is accumulated on filter elements while the air passes through the filter bags from outside to inside. The accumulated powder is dislodged from the bags by reverse pulse jet air intermittently. The dislodged powder falls on bottom cone and is discharged through powder discharge valves. The dust free air is sucked by induced draft fan and is exhausted to atmosphere.

Interconnecting Duct for Pulse Jet Air Bag Filter (APCD)

Get Price Quote

1 Piece (MOQ)

Bag Filter- Pulse Jet

Get Price Quote

1 Pair (MOQ)

We manufacture and supply bag filter on various application like induction furnace, banbury mixture, rolling mill furnace, coal handling plant, crusher and screen house, bunker house, sponge iron plants ,rice mill, cement plants coal based thermal power plant etc . bag filter for low and high temperature dusty air are supplied. Heavy-duty dust collector for dust collection, pollution control & product recovery, built in single unit or in modular construction is costumed designed specially to suit the application. pulse jet bag filter dust laden air enters the dust collector through the hopper or high –entry inlet housing section an internal baffle distributes the dirty air within, the housing ,so as to reduce air velocity and allow heavier particles drop into hopper, while lighter particle collects on the outside surface of the bags for operation of bag filters, suction hoods shall be connected to suction take off points. These suction take off points shall be connected to the main ducting by branch ducting and the other end of main ducting shall culminate into bag filters. The outlet of bag filter to inlet duct of blower and the same will exhaust clean air to atmosphere vide a stack.

Pulse Jet Bag Filter

Get Price Quote

Pulse Jet Dust Collector, Bag Filter

Get Price Quote

We are acknowledged in offering an exclusive range of Manual and Motorized Fabric Bag Dust Collector to our clients. This ravishing collection is processed using finest quality materials under the supervision of our creative and skilled professionals. Designed in compliance with standard quality, they are offered in a multitude of designs and patterns.

Pulse Jet Bag Filter

Get Price Quote

Reverse jet cleaned tubular bag filters designed for continuous operation in bulk handling and process applications. This on-line high efficiency reverse jet cleaning. Filter areas range from 9m2 to 820m2. All units have generous integral pre-separation chambers to increase their dust load capacity whilst reducing the load on the filter bags.Normal maintenance is from the top, within handrails if specified, but bag changing may be IT some Features Robust welded steel construction, Weatherproof for exposed locations, Compressed air pressure typically 6.0 bar ,large integral pre-separation chamber, Crushing, screening, sieving: from quarried minerals to pharmaceutical powders.

Pulse Jet Bag Filter

600,000 Per Unit

1 Piece(s) (MOQ)

Single Unit Pulse jet Bag Filter

Get Price Quote

The single unit pulse jet bag filter de-dusts by the air of individual dedusting points,It features linear air distribution, online de-dusting, cages with venturis, good de-dusting effects, modular design, simple structure, flexible assembly into multi-module units and good adaptability to dust load requirements

reverse pulse jet bag filter

Get Price Quote

Everybody wants to have clean and pollution free air around, and since industries are more responsible for Air pollution. We combat this section. There are several varieties of Bag Filter A Dust Collector is a system used to enhance the quality of air released from industrial and commercial processes by collecting dust and other impurities from air or gas. Designed to handle high-volume dust loads, a dust collector system consists of a blower, dust filter, a filter-cleaning system, and a dust receptacle or dust removal system. It is distinguished from air cleaners which use disposable filters to remove dust. In reverse-pulse-jet Bag Houses, individual bags are supported by a metal cage (filter cage), which is fastened onto a cell plate at the top of the Bag Houses. Dirty gas enters from the bottom of the Bag Houses and flows from outside to inside the bags. The metal cage prevents collapse of the bag. Bags are cleaned by a short burst of compressed air injected through a common manifold over a row of bags. The compressed air is accelerated by a venturi nozzle mounted at the Reverse-Jet Bag Houses top of the bag. Since the duration of the compressed-air burst is short (0.1s), it acts as a rapidly moving air bubble, traveling through the entire length of the bag and causing the bag surfaces to flex. This flexing of the bags breaks the dust cake, and the dislodged dust falls into a storage hopper below. Reverse-pulse-jet Dust Collectors can be operated continuously and cleaned without interruption of flow because the burst of compressed air is very small compared with the total volume of dusty air through the collector. Because of this continuous-cleaning feature, reverse-jet dust collectors are usually not compartmentalized. The short cleaning cycle of reverse-jet collectors reduces recirculation and redeposit of dust. These collectors provide more complete cleaning and reconditioning of bags than shaker or reverse-air cleaning methods. Also, the continuous-cleaning feature allows them to operate at higher air-to-cloth ratios, so the space requirements are lower. This cleaning system works with the help of digital sequential timer attached to the fabric filter. This timer indicates the solenoid valve to inject the air to the blow pipe.

Pulse Jet Bag Filter

50,000 Per Units

Pulse Jet Bag Filter

Get Price Quote

We are offering pulse jet bag filter. we are engaged in providing quality bag filters that are used in dedusting systems and can meet the most stringent air pollution codes. Our tangr of dust collector is specially designed to vent bins, storages silos, mixers, blenders, pneumatic conveying system of any type or any other device or process that must contain or control dust particles. some of its salient features are as follows: sturdy construction high efficiency less maintenance

Pulse Jet Bag Filter

Get Price Quote

As far as the usage are involved these are primarily used in air pollution control equipment. the best a part of this technique is that it will filter significant dust burdens and attain desired assortment potency at high temperature. Reverse Pulse Jet Bag Filter serves for dry separation of a dust from waste gas. so as to confirm quality we follow business standards in producing the product by using best material. we created these industrial pulse jet bag filters available at extremely reasonable rates. Bag filter Manufacturers Pulse Jet Bag Filter is an air pollution management device that extracts dust particulates from air or gas free from industrial processes or combustion for electricity generation.These are the list of industries which use pulse jet bag filter Power plants, steel mills, pharmaceutical producers, foods manufacturers, chemical industries and other industrial firms typically use bag filter to management emission of air pollutants. Bag filter Manufacturers are used widely for controlling on dust control. Bag filter Manufacturers.