Argon Purging Plug

17,000 Per Piece

1 Piece(s) (MOQ)

nitrogen purging services

Get Price Quote

Nitrogen purging services are essential for maintaining the safety and efficiency of industrial systems. This process involves the use of nitrogen gas to remove oxygen, moisture, or hazardous gases from pipelines, storage tanks, or equipment, preventing contamination, oxidation, or combustion. Widely used in industries like oil and gas, chemical, and pharmaceuticals, nitrogen purging ensures a safe environment during maintenance, startup, or shutdown procedures. Techniques such as displacement, dilution, or pressure purging are employed based on specific needs. With precision and adherence to safety standards, nitrogen purging services protect equipment integrity, enhance operational safety, and ensure compliance with environmental and industry regulations.

Best Deals from Purge Systems

nitrogen purging system

Get Price Quote

We are offering nitrogen purging system. A portable instrument used for purging of nitrogen gas into the other equipment using suitable attachment.

automatic argon purging systems

Get Price Quote

Argon purging system: as international technology makes remarkable progress in to the world of alloys, super alloys and special steels. The requirement for cleaner steel homogeneous chemical composition coupled with the need for reducing production cost as well as increasing productivity has led to development of more efficient metallurgical process become a necessity for mini steel plant. the process concern itself with production of wide range of steels & high grade alloys steels. The recognized benefits are: 1 • to make any type of qualitative steel production. 2 • homogenization of melt for chemical analysis. 3 • improvement of purity in terms of gaseous impurities. 4 • to reduce on metallic inclusion. 5 • total quality and killed metal. 6 • purging of argon gas from bottom of the ladle is through pours plug and the main roll of argon purging is to remove non-metallic inclusions from the steel which on purging of argon gas goes to the slag surface. 7 • argon purging shall ensure vigorous slag metal reaction. 8 • homogenization of temperature. 9 control of gases viz h2, n2 10 n2 is an impurity and is undesirable in steel 11 • nitrogen is reactive gas and during nitrogen purging it is picked up in steel and argon is non reactive gas that is best to use for best quality but costly. You can use some nitrogen in start of refining and then argon after that to reduce cost. 12 • argon being neutral gas & non reactive and being used all over the world for purging in steel making operations in secondary steel making. 13 • upper limit for nitrogen ppm varies from grade to grade. 14 • nitrogen is innert gas, there is no chemical reaction with steel. 15 • argon and nitrogen both are considered to be inert gases to be used as purging agents in ladle & furnace. However, you have to be careful while using nitrogen as a purging gas for those steel grades that contains elements like ti, nb, v etc. Which have strong affinity for nitrogen.

Purge Systems

80,000 Per Set

We are the main supplier of this product.

Purge Systems

Get Price Quote

Bebco EPS purge and pressurization by Pepperl+Fuchs is a household name in the process automation industry. As the leaders in Purging Technology, we manufacture innovative solutions that are remarkably simple to use and will easily handle just about any application.With Pepperl+Fuchs' Bebco EPS purging and pressurization, you get State-of-the-art solutions based on more than 20 years of experience a family of automatic purge and pressurization systems that make hazardous location protection easy Technical support anywhere in the world Purge and pressurization systems designed according to ATEX direction 949EG, NFPA 496, and ISA 12.4 standards Easy integration compact, low-profile designs that can be internally or externally mounted Automatic temperature and leakage control and alarming User interface with programming to meet most users' demands

Purge Systems

Get Price Quote

Ex pz purge systems reduce the classification within the protected enclosure from Zone 2 to non-hazardous. General-purpose equipment can be operated within the protected enclosure.

automatic argon purging systems

Get Price Quote

We are an eminent name, which is engaged in offering Automatic Argon Purging Systems to our clients. The offered range is designed utilizing premium grade components, sourced from reliable vendors of the market. In addition to this, the offered range is available in different customized designs, shapes and allied specifications in accordance with the diverse demands of clients. Product, which is incorporated in this range are mentioned below: In order to cater to the diverse demands of clients, we are able to offer Automatic Argon Purging Systems. Scrap is melted down in the melting furnace and after the tapping the liquid metal having a temperature 1600 to 1650oC is charged in to the Ladle. The liquid metal either slag or with slag is weighted and transferred with the help of charging crane to the LRF plant. First sample and temperature is taken from ladle. According to this analysis and measured temperature pre-calculation of Ferro-alloys, additives and Argon gas is effected to start from bottom of ladle process with using Argon purging system. To carry out Argon gases are blown in Ladle through porous plug installed in bottom side. An economical way of production of alloys steel. As international technology makes remarkable progress into the world of alloys & super alloys. the requirement for cleaner steelhomogeneous chemical composition coupled with the need for reducing the production cost as well as increasing productivity has led to development of more efficient metallurgical tools in secondary metallurgical process become a necessity for mini steel plant. The process concerns itself with production of wide range of steels & high grade alloys steels. The recognized benefits are : To make any type of qualitative steel production. Homogenization of melt for chemical analysis. Improvement of purity in terms of gaseous impurities. To reduce on metallic inclusions

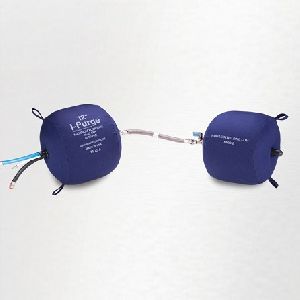

Purge Bladder

Get Price Quote

Purge Bladder I-Purge™ Modular Inflatable Bladder System, the most advanced and versatile solution for pipe purging, enables to accomplish a number of different purge requirements with one interchangeable solution. It is equipped with Quick Connect Fittings, components easily snap on and off in seconds! With the Isolator™ Adaptor Kit, a one sided plug can be created to close off the end of a pipe for servicing, cleaning, inspection or sealing. The Proprietary Relief Valve Technology enables the system to inflate at a precise rate. I-Purge Modular Systems are available in sizes 2 – 36 (51 – 914 mm) and can be customized to suit your specific purging requirement.

nitrogen purging system

Get Price Quote

Nitrogen Purging System for Defence & Air Craft System.

automatic argon purging systems

Get Price Quote

As international technology makes remarkable progress into the world of alloys & super alloys. the requirement for cleaner steel homogeneous chemical composition coupled with the need for reducing the production cost as well as increasing productivity has led to development of more efficient metallurgical tools in secondary metallurgical process become a necessity for mini steel plant. The process concerns itself with production of wide range of steels & high grade alloys steels.

X type Purge system

Get Price Quote

X type Purge system

Purge Systems

Get Price Quote

Purge Systems, Adjustable Nozzles, Frp Rods, steel band

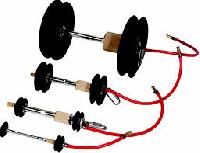

Inflatable Bag Weld Purge System

Get Price Quote

Inflatable Bag Weld Purge System, Industrial Hand Tools

Ex px Purge System

Get Price Quote

Ex px Purge System, Optical Identification, backplanes

Quick Purge Systems

Get Price Quote

Quick Purge Systems, Cutting Torch, Cnc Drilling Machine

Purge Systems

Get Price Quote

Purge Systems, Oxygen Indicators, orbital welding machine

Purge Systems for hazardous location

Get Price Quote

Purge Systems for hazardous location, Cabinet Type Air Conditioners

nitrogen purging system

Get Price Quote

nitrogen purging system, Industrial Gas

passenger purge systems

Get Price Quote

passenger purge systems, electric coolant pump, Electric Water Pump