Pusher Centrifuge

200,000 - 1,000,000 Per Unit

1 Unit (MOQ)

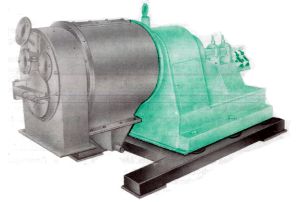

Pusher Centrifuge

Get Price Quote

1 Piece (MOQ)

The Pusher Centrifuge is basically used to seperate, slurries which are EASY TO FILTER, with an average crystal size of solids from 0.1mm (100 microns) to 10mm and fibre length of linter (for Fibrous materials) upto 30mm.

Best Deals from Pusher Centrifuge

Pusher Centrifuge P 60

Get Price Quote

We present the best quality Pusher Centrifuge that is designed to provide maximum efficiency and proper filtration. Our Pusher Centrifuges are manufactured with cutting edge technology to provide long term usage.

Pusher Centrifuge

Get Price Quote

Applications : Chemicals : Glauber’s salt, boric acid, ascorbic acid, adipic acid, sodium chloride, iron sulphate, sodium sulphate, copper sulphate, sodium dichromate. Fertilisers : Ammonium sulphate, potash, urea, calcium nitrate, potassium sulphate. Plastics / Explosive : PVC, polystyrene, polyethylene, polypropylene, linters, nitrocellulose. Food stuff / Animal feed : Extraction residues, meat pulp. Beneficiation : Rock phosphate, gypsum, ores, coal. Design Features : Complete separation of mechanical unit from the process area. Can be fitted with Long and Short or Single and two baskets. Can be fitted with Long and Short or Single and two baskets. Has easy accessibility for maintenance Low Energy Consumption and is Easy to install Process Area : Solids collecting housing and volute race discharge Identical housing for single and two-stage baskets Feed pipe or feed screw Various devices for the distribution of wash liquor “Wear protection package” available for abrasive products Oil pressure joints for simple assembly and disassembly of the basket and pusher plate Mechanical UnitSturdy welded construction of the bearing housing with incorporated oil pan and motor support. Vertically installed oil pump(s) which can be removed without draining of the oil. Hydraulic pusher control incorporated in the pusher piston.BasketThe internal basket is available in several alloys. The basket shall is perforated with large filtration holes. Single and two-stage baskets in the long or short versions are available for optimum solution of the separation requirements.Slot ScreensThe basket is fitted with a slot screen. The wedge bar profile and the slot width are chosen according to process requirements, i.e. depending on particle size distribution and slurry concentration. The slot width is usually between 0.1 and 0.5 mm.Hydraulics and Pusher ActionThe pusher plate (or inner basket for two stage units) is operated hydraulically. The spindle pump(s) vertically installed in the oil pan, supplies the required quantities of oil at up to 60 bar pressure. The reversing mechanism is integrated within the pusher piston. It consists of a hydraulically operated pre control valve. Stroke length adjustment is available as standard.

pusher centrifuges

Get Price Quote

1 Piece (MOQ)

Pharmaceutical Pusher Centrifuge

Get Price Quote

We are a well-known Manufacturer, Exporter and Supplier of Pharmaceutical Pusher Centrifuge. The Pharmaceutical Pusher Centrifuge is a continuous unit for solid-liquid separation. The solids are retained as a cake on the wedge wire screen and transported by an oscillating inner basket/pusher plate, which moves axially in the direction of solids discharge. The pushing frequency is adjustable to favor the washing efficiency and lower discharge moisture. The size of the separated solid particles is preferably greater than 80 micron. The thick, filter cake ensures a good yield of even very fine solids. Our Pharmaceutical Pusher Centrifuge are designed with one, two or three stages based on the application and filtration rate. Advantages Continuous separationUnmatched capacityMinimum floor spaceLow energy consumptionLow maintenance costLess particle breakageLow residual moistureHigh washing efficiencyConsistence product quality Selection Based On Type of productParticle size% of solids concentrationProduct washingNature of productRequired capacity Note Models beyond 500 mm and up to 900 mm are also available on request.Output of other products depend upon slurry concentration, sp. Gravity, particle size and other propertiesWe reserve the right to make any changes required by technical advances and as per our experiences

pusher centrifuges

Get Price Quote

Pusher Centrifuge

Get Price Quote

Pusher Centrifuge

600,000 Per Piece

Pusher Centrifuge

Get Price Quote

Centrifuge machine is normally used for seperation of solid liquid mass. A Pusher Centrifuge has several advantages over normal mechanical centrifuge machine, which can be stated as follows. High throughput and bulk handling capacity Practically no manpower required for operation and is a fully automated continuous operation. Higher production rate with minimum maintenance and space requirements. More energy efficient and reduce operating cost. Very effective dewatering of coarse crystalline products at high throughput rate and also the quality of the finished products can be improved by variety of washing modes. Can be used for variety of products and applications in bulk chemicals, Plastics, and mineral products with particle size approximately 100 microns and above.

Pusher Centrifuge

Get Price Quote

We are offering Pusher Centrifuge of international standard, several models to suit your product. this continuous pusher centrifuge will reduce your labor force, number of units required, floor space, operational workload in addition to saving on spillage of your expensive products. ease of operation and efficient performance will increase your productivity at lower unit cost

Pusher Centrifuge

Get Price Quote

Pusher Centrifuge

Get Price Quote

Oriental Pusher Centrifuges provide the features for cost effective, high output and minimum maintenance for your solidliquid separation need. Our GERMAN design assures a sturdy horizontal Centrifuge machine with efficient operation. Effective dewatering with high filtration rates and option to automize the process, makes Oriental bottom discharge centrifuges the first choice for the industry. The effective washing arrangement increases the quality of finished product. Oriental Horizontal Bottom Discharge Pusher Centrifuges can be used in wide spectrum of application, ranging from bulk chemicals, agricultural and petro chemical industries. Our continuous pushers can give constant outputs for months together without any hiccups.

Mechanical Pusher Centrifuge Machine

Get Price Quote

Pusher Centrifuge

Get Price Quote

Pharma Pusher Centrifuge

Get Price Quote

Chem Tech Equipments is counted among the prominent Manufacturers, Exporters and Suppliers of Pharma Pusher Centrifuge in India. Quite a space-saver, this Pharma Pusher Centrifuge ensures Continuous separation with minimal particle breakage. This is also appreciated for features like Low residual moisture, High washing efficiency, unmatched capacity, energy efficiency as well as zero maintenance. Features Minimum floor spaceLow energy consumptionLow maintenance costLess particle breakageLow residual moistureHigh washing efficiencyConsistent product quality

Pusher Centrifuge

1,500,000 Per Piece

1 Piece(s) (MOQ)

Pusher centrifuge is a continuous filtering type centrifuge used for solid-liquid separation in the chemical and mineral industries.

Pusher Centrifuge

Get Price Quote

PUSHER CENTRIFUGE With simple robust design the Pusher Centrifuge gives high throughputs under the toughest conditions. Operates purely on with mechanical drive the Pusher Centrifuge is suited for all fields for the separation of slurries with solid which filters easily. The average particle size of the solids must be at least 0.1 mm. Pusher Centrifuge utilizes continuous Filtration for the suspended, fast draining, crystalline and granular or fibrous solids from the liquid phase. These solids can be washed as they are transported though the basket.

Pusher Centrifuge

Get Price Quote

Pusher Centrifuge, Decanter Centrifuge, Horizontal Scraper Centrifuge

continuous pusher centrifuges

Get Price Quote

continuous pusher centrifuges, air receiver vessel, Security Cameras