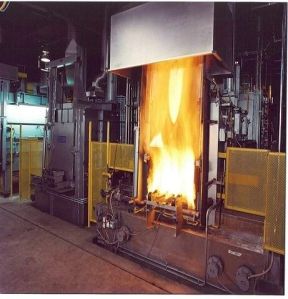

Sealed Quench Furnace

Get Price Quote

Drop Bottom Quench Furnace

300,000 Per Piece

Best Deals from Quench Furnace

Sealed Quench Furnace

Get Price Quote

We are actively engaged in providing a range of Sealed Quench Furnace, which is inclusive of Conveyor Type Furnace, Continuous Furnace and Batch Type Furnace. Available in different specifications, our Straight Through, Sealed Quench Furnace is widely demanded, owing to its superb quality and accurate functionality. From Maharashtra, India, we are the credible Manufacturer, Exporter and Supplier of Sealed Quench Furnace. For rock bottom prices, contact us. Specifications : The applications of Sealed Quench Furnace are as follows: Carburizing Carburizing-Hardening Carbonitriding Hardening Bright Annealing Controlled atmosphere annealing Normalizing Re-carburizing

Pin Type Lost Wax Loading Grids for Sealed Quench Furnace

Get Price Quote

Drop Bottom Quench Furnace

160,000 Per Piece

2 Piece (MOQ)

Heat Treatment Furnaces, Rapid Quench Furnaces

Get Price Quote

We offers heat treatment furnaces, rapid quench furnaces. Annealing normalising hardening solution treatment heating forge heating tempering aluminum solutionising stress relieving ductile iron full annealing.

Drop Bottom Quench Furnace

Get Price Quote

1 Number (MOQ)

Drop Bottom Quench Furnace

350,000 Per UNIT

1 UN (MOQ)

sealed quench furnaces

Get Price Quote

The multipurpose batch type chamber furnace plants or Sealed Quench Furnaces has revolutionized the heat treatment industry in the last few decades thanks to its versatility, easy integration in automatic treatment lines, providing flexibility of metallurgical processes, product mix and layout, with maximum quality heat treatment in terms of reliability, predictability and repetitiveness. These plants are normally coupled with companion equipment like Preheating and Tempering Furnaces, Washing Machines, Stationary Table, Scissor Lifts and fully automated one or more Charge Transfer Cars- all designed for maximum reliability.

Quench Furnace

Get Price Quote

Quench pressure, up to ten times atmosphere pressure (10-bar), can be used to quickly and thoroughly quench (cool) even the heaviest and thickest cross-sections after heating. This high capacity quench capability insures full and complete hardening of the material.

Sealed Quench Furnace

6,000,000 Per unit

Industrial Drop Bottom Quench Furnace

230,000 - 900,000 Per unit

Drop Bottom Quench Furnace

Get Price Quote

Sealed Quench Furnace

Get Price Quote

Uniform heating through close pitch radiant tubes located on either side from top. Options for electric / gas fired radiant tubes available • Fully automated control systems with PLC, Thyristor with PID temperature control, Carbon potential controller and scada system • Touch screen graphic operator panel with alarm annunciation,Multi point temperature recorder • Cast integral fan for uniformity of temperature and atmosphere • Silicon carbide skids or Heat resistant steel T-rails • Pneumatically operated doors, Elevators etc. • Options for using Endo gas, Nitrogen-Methanol LPG Process Atmospheres • Integrated and compact layout with Washing, Tempering and Material handling equipment at economical prices • Turnkey project offered with process knowhow • All alarms and annunciation with inter locks are provided for operating safety • Low Low cost spares with easy availability Applications Carburising & Hardening Carbo Nitriding Carburising & Annealing Bright Hardening Nitro Carburising Normalising

DROP BOTTOM QUENCH SOLUTION TREATMENT FURNACE

Get Price Quote

DBQ or drop bottom quench solution treatment furnace is primarily used for solutionizing of aluminium parts prior to forming. The requirement is a quick quenching of aluminium parts usually within 5 to 10 seconds so that the material comes to ideal precipitation hardened condition. When heated evenly to a temperature of upto 550°C, a solid solution of copper is formed in the aluminium structure which flows throughout the microstructure. The furnace is inverted type with charge lifting and lowering facility to accommodate the high speed quenching including de-clamping, door opening and quenching. The furnace can be stand alone type with charge carrier loader and quenching tank moving on the floor or floor mounted with charge carrier loader and quench tanks sliding in a pit. As the requirement is very fast quenching it is fully automated by the use of PLC and SCADA. These furnaces can also be used for continuous ageing cycle ranging from 16 – 24 hrs time. Various quench media such as water, glycol or other polymer oils as per process requirement are used. Area of application is generally used in aeronautical industries for solutioninzing and ageing of structural parts, also in forging industries of aluminium alloy forgings.

Quench Furnace

500,000 Per Units

Quench Furnace

1,000,000 Per Piece

Drop Bottom Quench Solutionizing Furnace

120,000 Per Units

Drop Quench Solution Annealing Furnace

Get Price Quote

Heat treatment of aluminium castings enhances their mechanical properties like UTS, Yield strength, Machinability and hardness. In the solution annealing procces, castings are taken to their eutectic temperature and then rapidly quenched in water. Equipment provided by Energy Systech includes the entire material handling system required to achieve this. Uniformity of temperature in the furnace results in very consistent properties in the castings. Salient Features 1) Strong Elevated structure. 2) Powerful air circulation in circular geometry giving excellent temperature uniformity. 3) Ceramic Fibre lining giving excellent energy economy. 4) Reliable, long life vertical heaters. 5) Mechanical Up/Down motion with “dunking” facility. 6) Powered movement of Tank and Door trolley. 7) Sharp, quick quenching within 15 seconds. 8) Can also act as a Precipitation hardening furnace.

quench fork Gas fired Box furnace

Get Price Quote

Gas fired Box furnace with quench fork for water quenching of Stainless Steel castings